16

OPERATION AND USE TIPS

SHAPE OF THE DETECTION BEAM AND LINE OF SIGHT

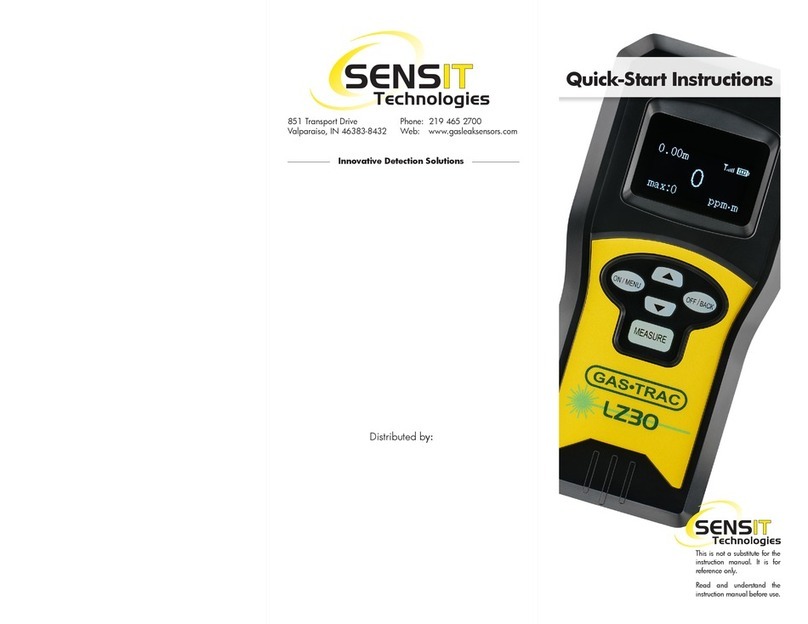

Due to the GAS•TRAC LZ-30 using a point of light for targeting, it can be easy to forget that the actual

detection path is in the shape of a cone, which starts from a point (the instrument) and gets wider on the

path to the target. At a distance of 30m (100ft.), this width is 20cm (8in.).The operator will get the most

consistent results if he/she keeps as much of this path in/over the target as possible.

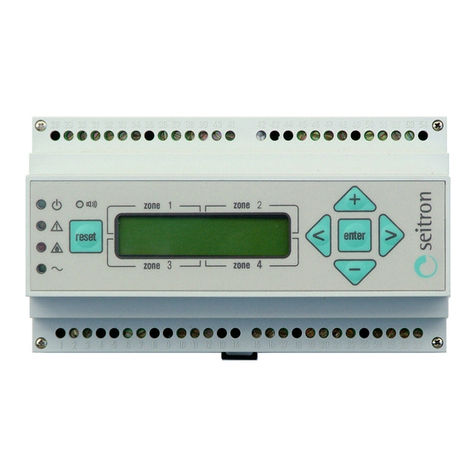

Because of this, some situations can present a challenge,

such as if part of the beam is reflecting off of a different

surface than another. This is known as “beam skipping”.

The operator will get the most consistent results if he/

she keeps as much of this beam in/over the target as

possible.

In the picture to the right (beam not to scale), part of

the beam is partially blocked by the fence, potentially

causing reduced sensitivity, or in some cases, false

positives. The operator should simply move slightly to the

left, ensuring that the full width of the beam will make it

to the target.

If the operator were surveying the ground behind the

fence, this wouldn’t be too great of a mismatch, but if the

target was the face of the building in the background,

there would be a very large difference in return signal

between the portion of the beam that is hitting the

building and the portion that is hitting the fence.

SHAPE OF THE DETECTION BEAM AND LINE OF SIGHT

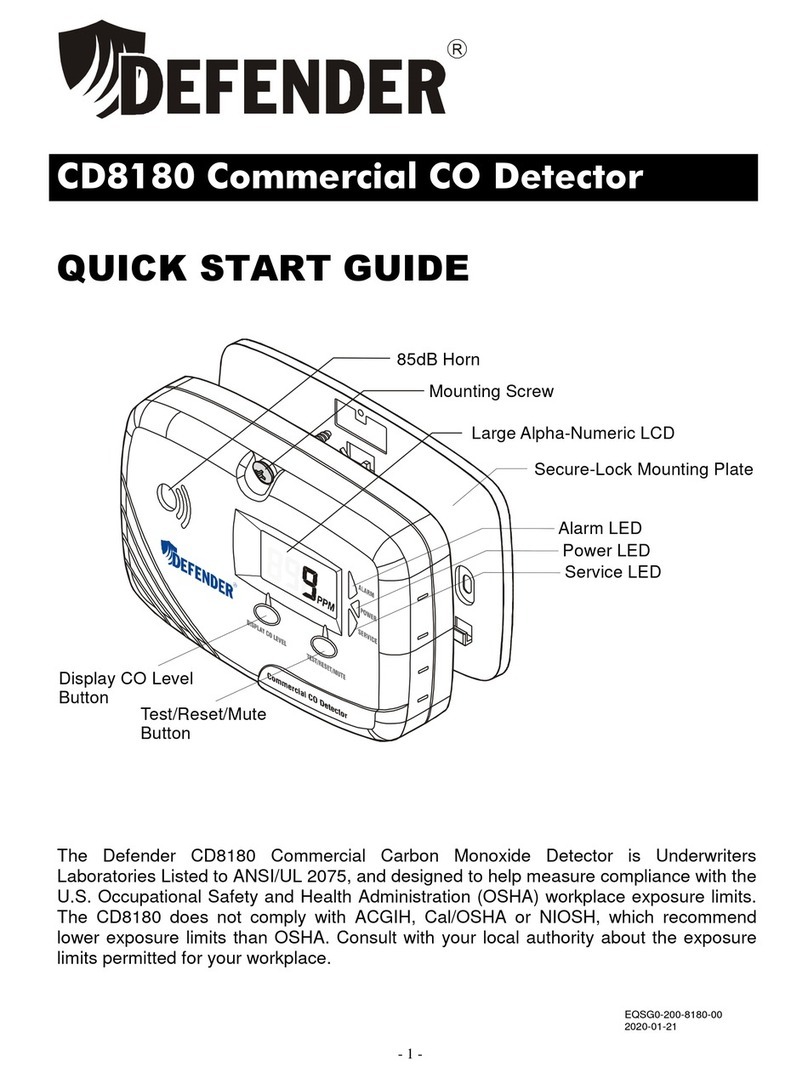

Another thing to consider is that the size of the beam can affect the

reading that the instrument gives, depending on the size of the plume.

Consider the picture to the right: the green colored beam is roughly the

same size as the plume of gas, which means that the instrument will be

reading only that plume. In the case of the red beam, only half of it is

traveling through the plume, meaning that the result on-screen is going

to be lower because part of what is being analyzed is gas-free air.

What this means is that the distance between the operator and the

plume can potentially affect the reading, because the beam expands

with distance. Realistically, though, it is unlikely to cause a noticeable

effect due to the gas plume naturally dispersing over a (relatively) large

area. Where this might be more noticeable is if the operator is far

away from a very small pinpoint leak. Most of the beam will not be

hitting the plume, and will lower the reading.

In a real-world scenario, a gas plume doesn’t have strictly defined

edges like this, and the operator obviously won’t be aware of where it

is to begin with. However, what this illustrates is that technology of this nature makes it near-impossible to

get true quantitative results. There are simply too many variables. Qualitative investigation and pinpointing

is where it shines.