AR-SP6N/RP6N OPEREATIONAL DESCRIPTIONS

– 5 –

[5] OPEREATIONAL DESCRIPTIONS

1. Major parts of the paper feed section 2. Out line of operations

QAR-RP6N (RSPF)

[Duplex documents]

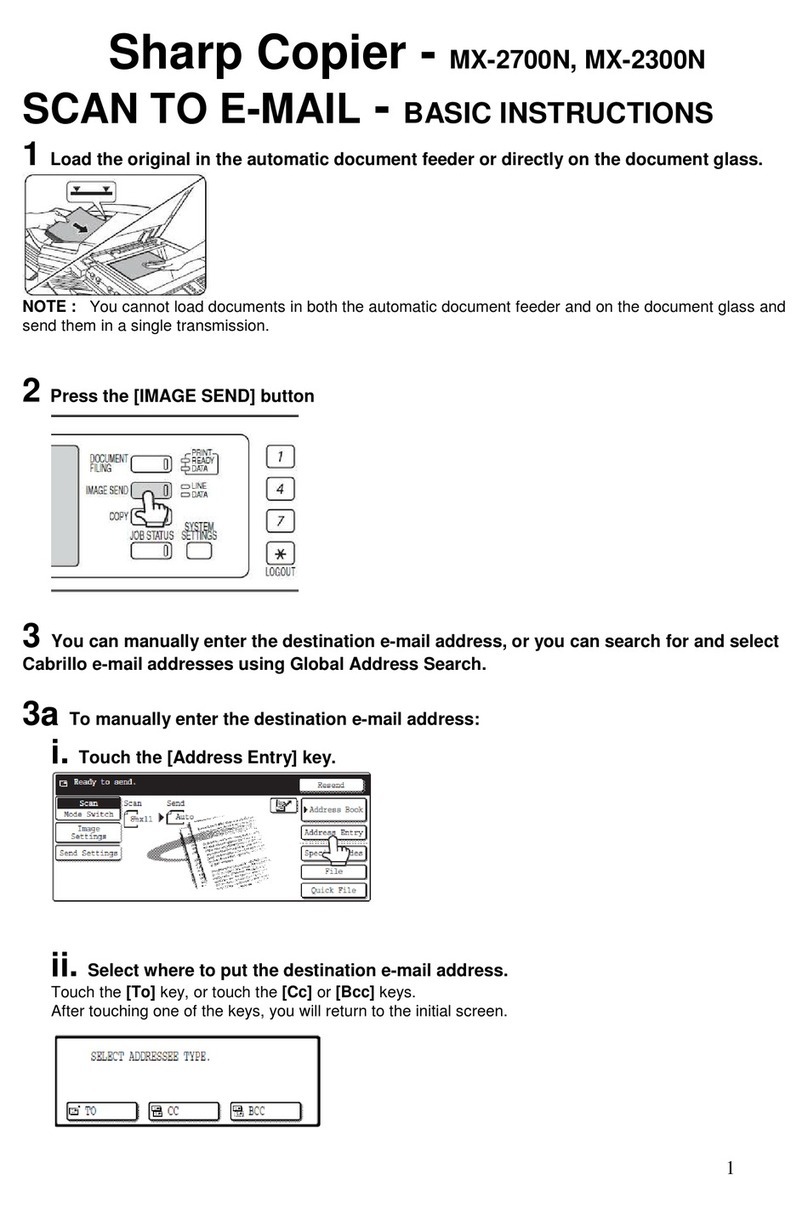

1) Document set (Document set sensor ON)

4

2) Document size detection (Document width sensors W1, W2, W3

detect the document width, and docu-

ment length sensors L1, L2 detect the

document length.)

4

3) Copier COPY key ON

4

4) RSPF motor ON

4

5) Pickup solenoid ON

4

6) Pickup roller and paper feed roller rotation

4

7) Paper entry sensor detects the document presence.

4

8) PS roller rotation

4

9) Copying (Front surface of document)

4

10) Transport roller rotation

4

11) Paper exit roller rotation

4

12) Paper exit gate falls down.

(Documents are discharged to the intermediate tray.)

4

13) Reverse gate falls down.

4

14) Paper exit roller reverse rotation

(Documents are fed to the reverse path.)

4

15) Paper entry sensor detects document presence.

4

16) PS roller rotation

4

17) Copying (Back surface of document)

4

18) Transport roller rotation

4

19) Paper exit roller rotation

4

20) Paper exit gate falls down

(Documents are discharged to the intermediate tray.)

4

21) Reverse gate falls down.

4

22) Paper exit roller reverse rotation

(Documents are fed to the reverse path.)

4

23) Paper entry sensor detects document presence.

4

24) PS roller rotation

4

25) Paper exit roller rotation

4

26) Paper exit gate lifts up.

4

27) Documents are fed to the paper exit tray.

4

28) Next document 3(YES) 3Go to 4).

4 (NO)

29) RSPF motor OFF

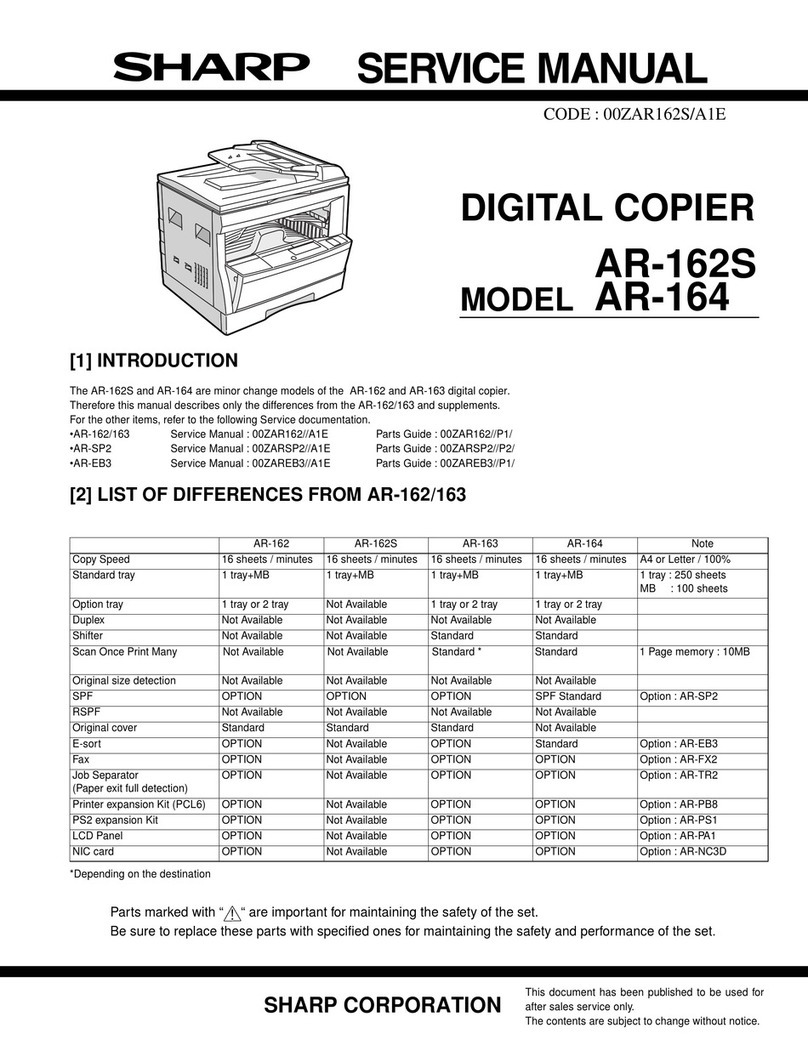

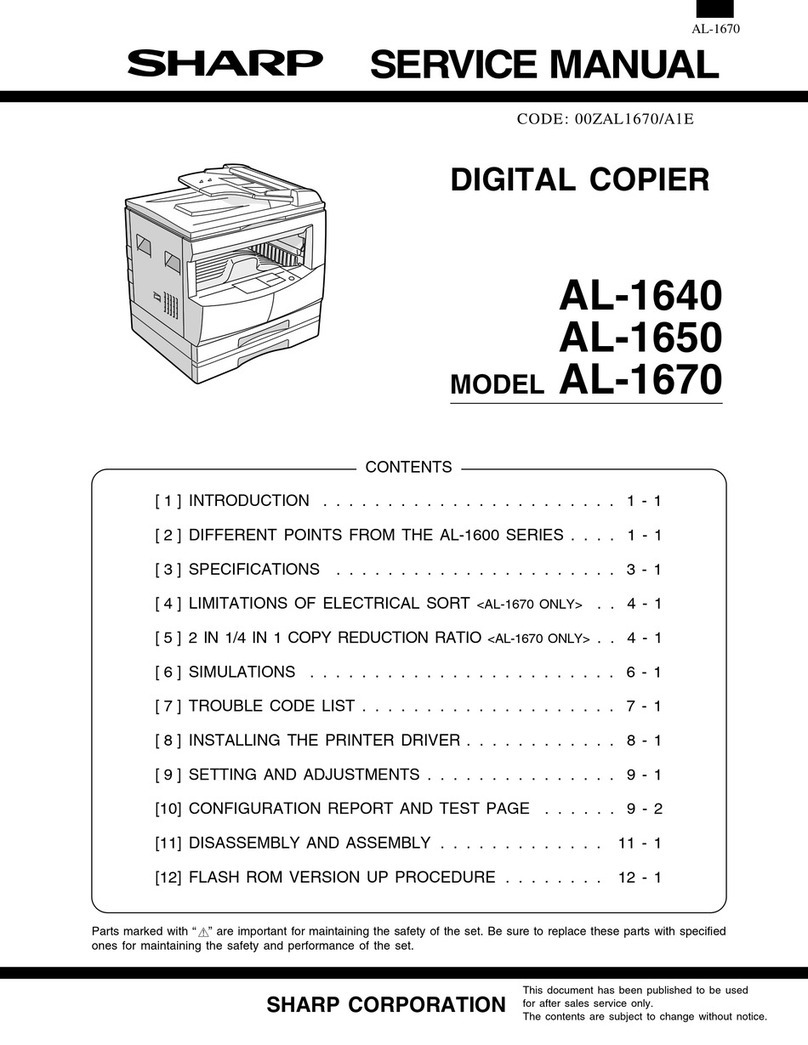

No. Part name Operation Note

1 Document length

sensor (L2) Detects the document length

on the tray.

2 Document length

sensor (L1) Detects the document length

on the tray.

3 Document set

sensor (W0) Detects presence of docu-

ments.

4 Document width

sensor (W1, W2, W3) Detects the document width.

5 Pickup roller Picks up documents.

6 Paper feed roller Feeds and transports docu-

ments.

7 Paper entry sensor

(PAPER) Detects transport of docu-

ments.

8 PS roller Makes synchronization

between the document lead

edge and the image lead

edge.

9 PS follower roller Makes synchronization

between the document lead

edge and the image lead

edge.

10 Transport roller Transports documents.

11 Transport follower

roller Transports documents.

12 Paper exit sensor

(PO) Detects transport of docu-

ments.

13 Paper exit follower

roller Discharges documents.

14 Paper exit roller Discharges documents.

15 Reverse gate Opens/closes the document

reverse path.

16 Paper exit gate Separate document exit to

the intermediate or the paper

exit tray.

AR-RP6N

only

17 Intermediate tray Dischargesdocuments to the

intermediate tray during doc-

ument reverse.

AR-RP6N

only

1 2 3,4 5 6 7 8

910111314 151617 12