Showa Denko Shodex OHpak LB-800 Series User manual

This manual suits for next models

14

Table of contents

Other Showa Denko Laboratory Equipment manuals

Showa Denko

Showa Denko Shodex RSpak NN-814 User manual

Showa Denko

Showa Denko Shodex RSpak JJ-50 2D User manual

Showa Denko

Showa Denko Shodex RSpak DS-413 User manual

Showa Denko

Showa Denko Shodex Asahipak GF-HQ Series User manual

Showa Denko

Showa Denko Shodex RSpak DM-614 User manual

Showa Denko

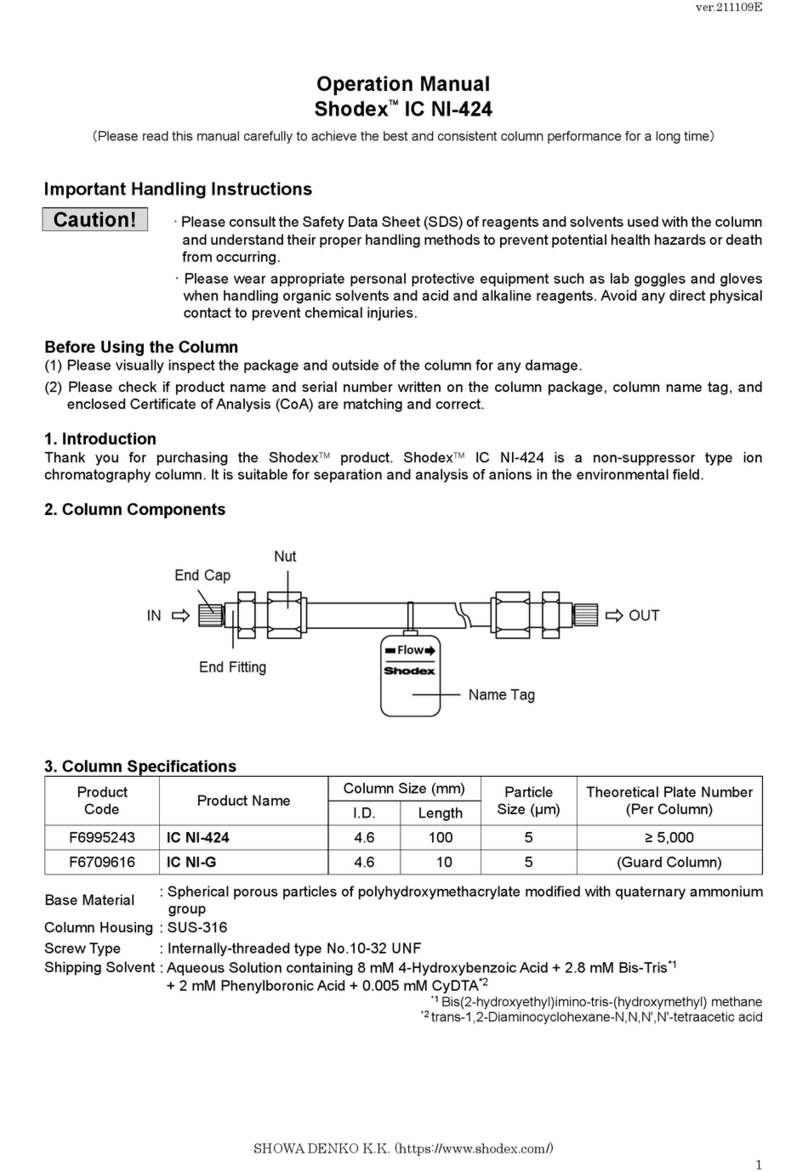

Showa Denko Shodex IC NI-424 User manual

Showa Denko

Showa Denko Shodex IC SI-90 4E User manual

Showa Denko

Showa Denko Shodex Asahipak GS-HQ Series User manual

Showa Denko

Showa Denko Shodex C18U 2B User manual

Showa Denko

Showa Denko Shodex SUGAR SP0810 8C User manual

Showa Denko

Showa Denko Shodex GPC LF-404 User manual

Showa Denko

Showa Denko Shodex PROTEIN LS-G 4J User manual

Showa Denko

Showa Denko Shodex GPC LF-604 User manual

Showa Denko

Showa Denko Shodex ODP2 HP-2B User manual

Showa Denko

Showa Denko Shodex IC Y-521 User manual

Showa Denko

Showa Denko Shodex GPC KD-800 Series User manual

Showa Denko

Showa Denko Shodex ORpak CDBS-453 User manual

Showa Denko

Showa Denko Shodex Asahipak NH2P-50 10E User manual

Showa Denko

Showa Denko Shodex RI-101 Installation and user guide

Showa Denko

Showa Denko Shodex Shodex IC SI-36 4D User manual

Popular Laboratory Equipment manuals by other brands

Cleaver Scientific

Cleaver Scientific CSL-CELLAS instruction manual

Centurion Scientific

Centurion Scientific Pro-Research instruction manual

Newport

Newport Oriel VeraSol LSS-7120 user guide

Thermo Scientific

Thermo Scientific mySPIN 6 instruction manual

Tuttnauer

Tuttnauer 6690 STS-1V Operation & maintenance manual

Yamato

Yamato RE201 instruction manual

Hameg

Hameg HM8123 user manual

WLD-TEC

WLD-TEC gasprofi1 micro operating instructions

IKA

IKA WiCo T25 Easy Clean Control operating instructions

Leica BIOSYSTEMS

Leica BIOSYSTEMS VT1000 S Instructions for use

Waters

Waters Magnet+ user manual

Agilent Technologies

Agilent Technologies ZORBAX RRHT Series user guide