OPERATING INSTRUCTIONS| Bulkscan LMS5118014829/ZNC5/2017-06-06| SICK

Subject to change without notice

3

Inhalt

1 About this document .......................................................................................6

1.1 Purpose of this document ........................................................................................6

1.2 Target group...............................................................................................................6

1.3 Information depth .....................................................................................................6

1.4 Scope .........................................................................................................................6

1.5 Abbreviations used....................................................................................................7

1.6 Symbols used ............................................................................................................7

2 On safety............................................................................................................8

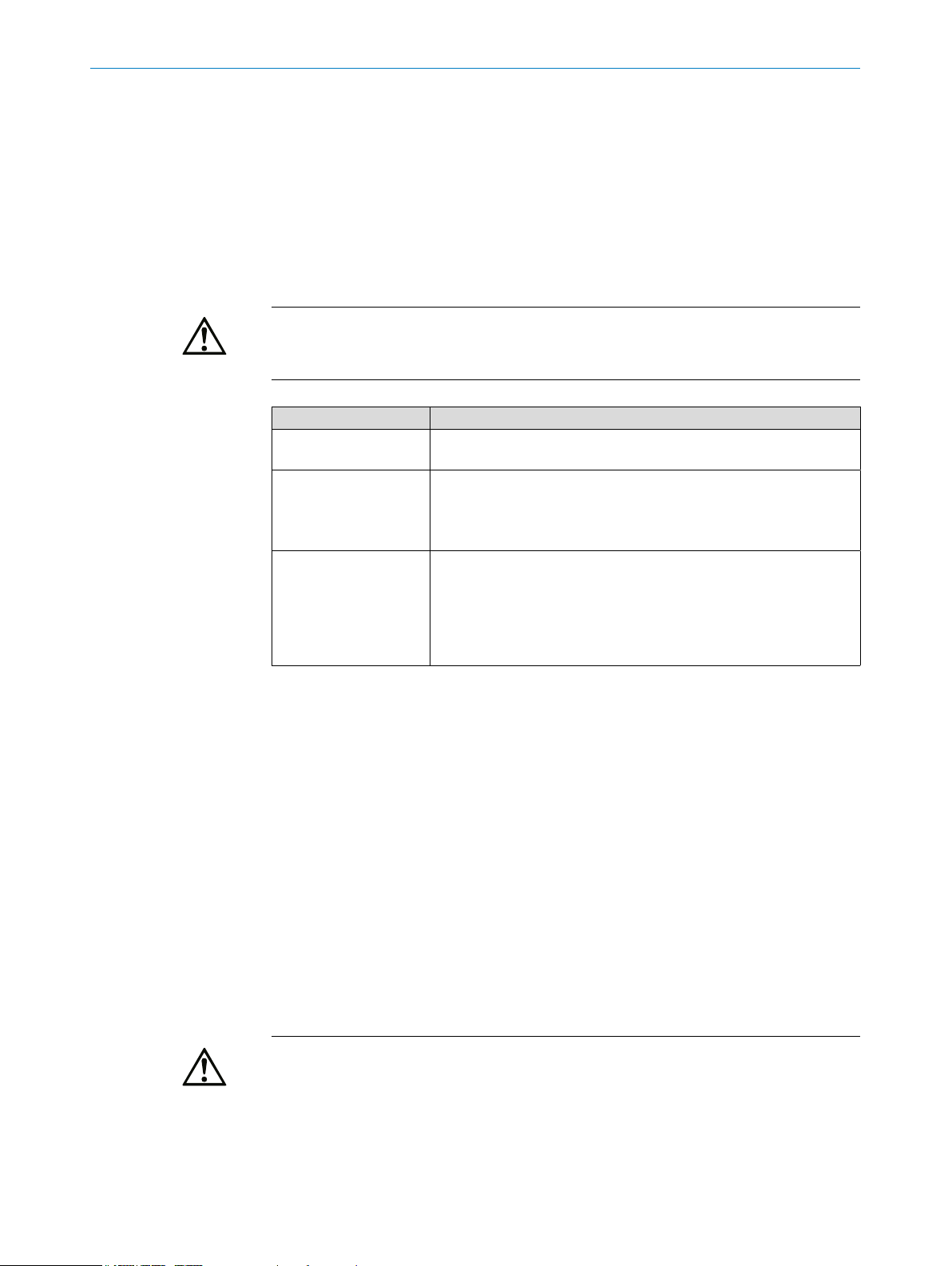

2.1 Authorized personnel................................................................................................8

2.2 Correct use ................................................................................................................8

2.3 General safety notes and protective measures.......................................................8

2.3.1 Electrical installation work........................................................................9

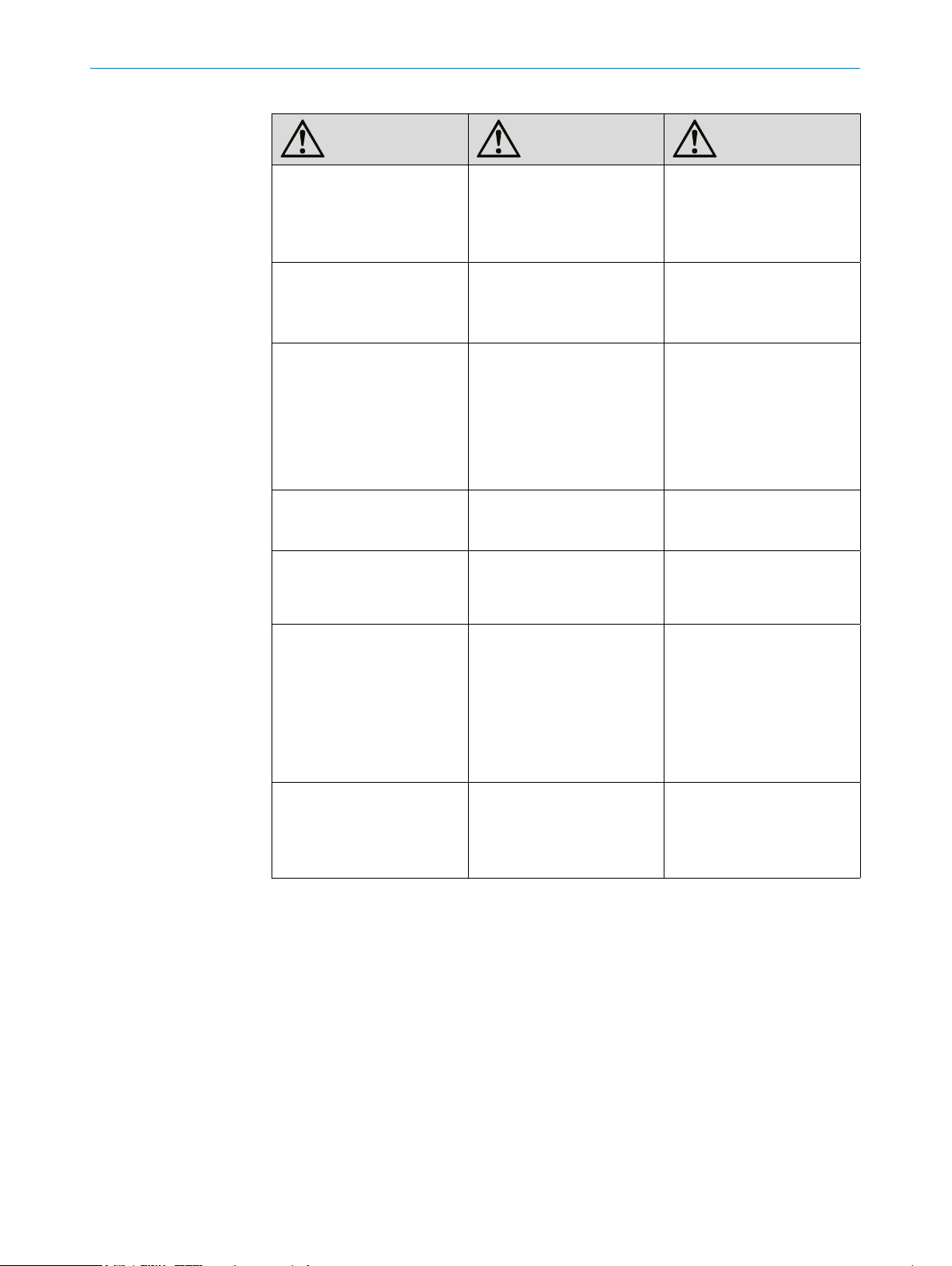

2.3.2 Laser radiation...........................................................................................9

2.3.3 Damaging potential equalization currents due to different ground po-

tentials 11

2.4 Quick stop and quick restart ................................................................................. 11

2.5 Environmental protection ..................................................................................... 12

2.5.1 Power consumption................................................................................ 12

2.5.2 Disposalafternaldecommissioning ................................................... 12

2.6 IP technology .......................................................................................................... 12

3 Product description....................................................................................... 13

3.1 Special features of the Bulkscan .......................................................................... 13

3.2 Operating principle of the Bulkscan...................................................................... 13

3.2.1 Measurement principle ......................................................................... 13

3.3 Application examples............................................................................................. 14

3.4 Status indicators .................................................................................................... 15

4 Congurable functions ................................................................................. 16

4.1 Setting the belt speed............................................................................................ 16

4.2 Measurement of the volume ................................................................................. 17

4.3 Measurement of the mass .................................................................................... 17

4.4 Measurementofvolumeowrate ........................................................................ 18

4.5 Measurementofthemassowrate ..................................................................... 18

4.6 Measurement of the bulk density ......................................................................... 19

4.7 Measurement of the bulk height........................................................................... 19

4.8 Monitoring the center of gravity ............................................................................ 20

4.9 Monitoring the bulk edge....................................................................................... 22

4.10 Monitoring the conveyor belt edge........................................................................ 23

4.11 Averaginglter........................................................................................................ 24

4.12 Digital inputs........................................................................................................... 24

4.13 Digital outputs ........................................................................................................ 25

4.14 Analog module BAM100........................................................................................ 26

4.15 Data interfaces....................................................................................................... 27

4.15.1 Ethernet interface................................................................................... 27

4.15.2 Serial host interface ............................................................................... 27

4.15.3 Serial auxiliary interface/USB................................................................ 28