Contents

1 Information on the operating instructions..................................... 5

2 About this document........................................................................ 6

2.1 Further information................................................................................... 6

2.2 Symbols and document conventions...................................................... 6

2.3 Customer service...................................................................................... 6

3 Safety information............................................................................ 8

3.1 Intended use............................................................................................. 8

3.2 Improper use............................................................................................. 8

3.3 Limitation of liability................................................................................. 8

3.4 Requirements for skilled persons and operating personnel.................. 9

3.5 Hazard warnings and operational safety................................................. 9

4 Product description........................................................................... 10

4.1 Product ID.................................................................................................. 10

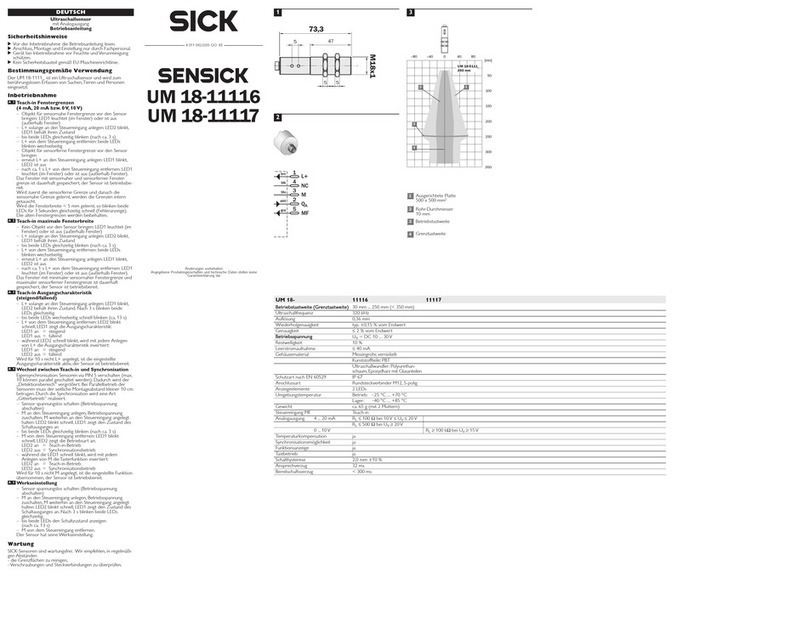

4.1.1 Device view............................................................................... 10

4.2 Product characteristics............................................................................ 10

4.2.1 Product features...................................................................... 10

4.2.2 Status indicators...................................................................... 11

4.2.3 System architecture................................................................. 11

4.3 Vibration analysis (Index 4474-4588).................................................... 12

4.3.1 Principle of operation.............................................................. 12

4.3.2 Settings for vibration analysis (Index 4477, 4479, 4482,

4531)........................................................................................ 12

4.3.3 Trigger (Index 4474-4475)...................................................... 15

4.3.4 Activity detection (Index 4479-4480).................................... 16

4.3.5 Vibration in time range (Index 4483-4539)........................... 16

4.3.6 Vibration in the frequency range............................................ 18

4.4 Temperature monitoring (Index 4352-4355).......................................... 19

4.5 Shock (Index 4434–4448)...................................................................... 19

5 Transport and storage....................................................................... 20

5.1 Transport................................................................................................... 20

5.2 Transport inspection................................................................................. 20

5.3 Storage...................................................................................................... 20

6 Mounting............................................................................................. 21

6.1 Mounting requirements............................................................................ 21

6.2 Mounting................................................................................................... 21

6.3 Mounting methods................................................................................... 21

6.4 Optional accessories................................................................................ 23

7 Electrical installation........................................................................ 24

7.1 Safety......................................................................................................... 24

CONTENTS

8028041/2022-08-16 | SICK O P E R A T I N G I N S T R U C T I O N S | MPB10 3

Subject to change without notice