Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Explanation of symbols............................................................................ 5

1.3 Further information................................................................................... 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 7

2.3 Cybersecurity............................................................................................ 7

2.4 Limitation of liability................................................................................. 8

2.5 Modifications and conversions................................................................ 8

2.6 Requirements for skilled persons and operating personnel.................. 8

2.7 Operational safety and specific hazards................................................. 9

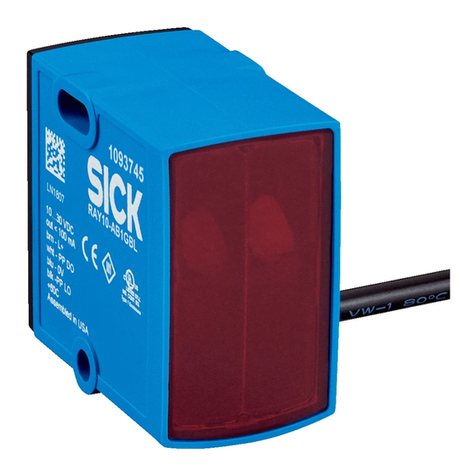

3 Product description........................................................................... 10

3.1 Scope of delivery....................................................................................... 10

3.2 Status indicators....................................................................................... 10

3.3 Type label.................................................................................................. 10

3.4 Principle of operation............................................................................... 11

3.4.1 Measurement principle........................................................... 11

3.4.2 Range finding........................................................................... 11

3.4.3 Direction measurement.......................................................... 11

3.4.4 Impact of object surfaces on the measurement................... 12

3.4.5 Beam diameter and measuring point distance..................... 14

3.4.6 Minimum object size................................................................ 16

3.4.7 Maximum and average pulse rate.......................................... 17

3.4.8 Output of measured values..................................................... 18

3.4.9 Multi-echo analysis.................................................................. 18

3.4.10 Field application (LD-LRS3600)............................................. 19

3.4.11 Integration into other controllers............................................ 20

4 Transport and storage....................................................................... 24

4.1 Transport................................................................................................... 24

4.2 Unpacking.................................................................................................. 24

4.3 Transport inspection................................................................................. 24

4.4 Storage...................................................................................................... 24

5 Mounting............................................................................................. 25

5.1 Mounting instructions............................................................................... 25

5.2 Mounting the device................................................................................. 25

5.3 Mounting multiple devices....................................................................... 25

6 Electrical installation........................................................................ 26

6.1 Wiring instructions.................................................................................... 26

6.2 Prerequisites for safe operation of the device........................................ 26

CONTENTS

8016506/1G07/2020-11-08 | SICK O P E R A T I N G I N S T R U C T I O N S | LD-LRS 3

Subject to change without notice