SICK WSO26 A0 Series User manual

Other SICK Accessories manuals

SICK

SICK UM12 Series User manual

SICK

SICK GSE6L Series User manual

SICK

SICK GRTB18SV User manual

SICK

SICK Bluetooth WLA16 User manual

SICK

SICK SureSense HTB18L Series User manual

SICK

SICK CS81-P3612S02 User manual

SICK

SICK GSE2 Flat Side User manual

SICK

SICK Flexi Loop User manual

SICK

SICK TriSpectorP1000 User manual

SICK

SICK OD1000 User manual

SICK

SICK KTX Prime KTX-WB91141259ZZZZ User manual

SICK

SICK WS24-2 Series User manual

SICK

SICK MPS-G 1108675 User manual

SICK

SICK CSS High Speed User manual

SICK

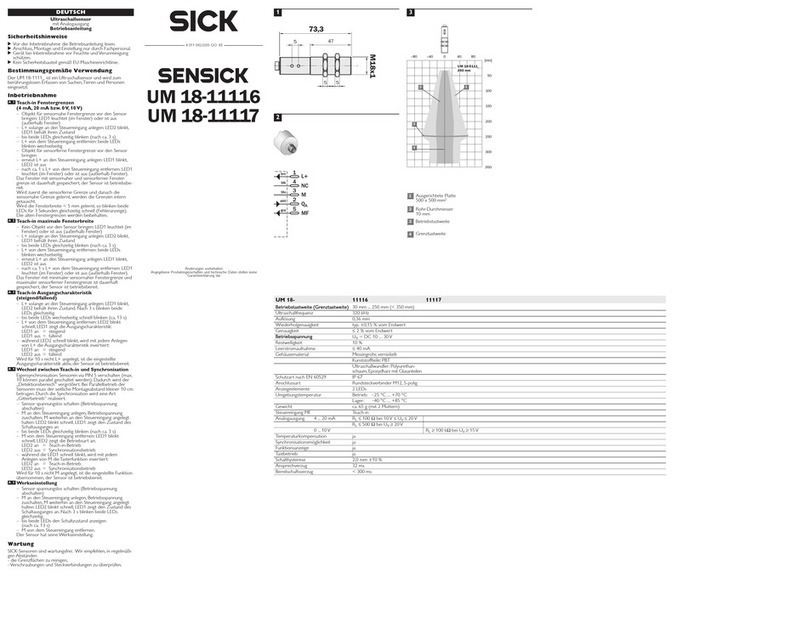

SICK SENSICK UM 18-11116 User manual

SICK

SICK GTB6L User manual

SICK

SICK W4F User manual

SICK

SICK GLD20 User manual

SICK

SICK LFV 330 User manual

SICK

SICK Inspector PIM60 User manual