Contents

1 About this document........................................................................ 5

1.1 Further information................................................................................... 5

1.2 Symbols and document conventions...................................................... 5

2 Safety information............................................................................ 6

3 Intended use...................................................................................... 7

4 Product description........................................................................... 8

4.1 Product identification............................................................................... 8

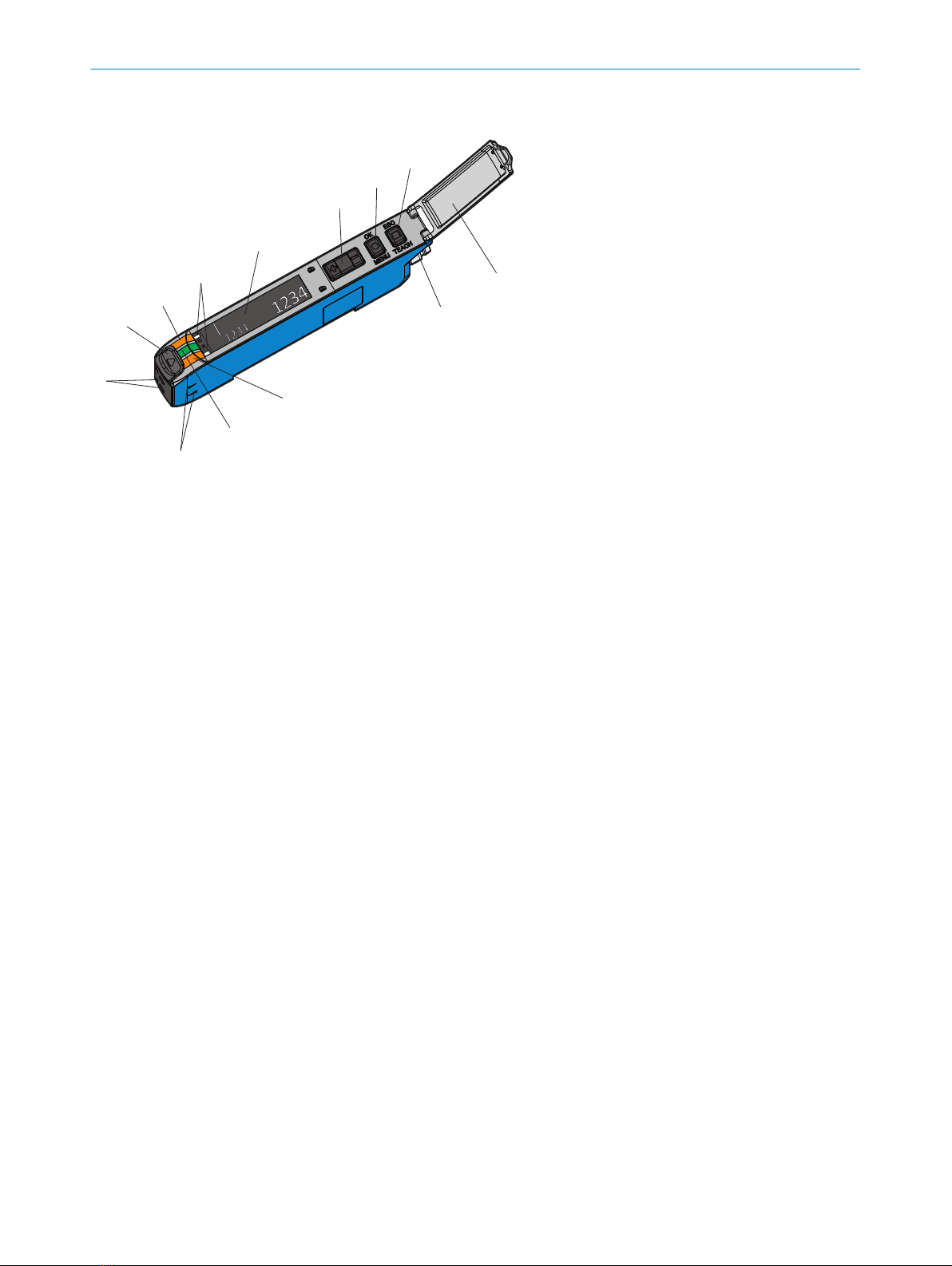

4.2 Device overview........................................................................................ 9

5 Mounting............................................................................................. 10

5.1 Scope of delivery....................................................................................... 10

5.2 Mounting requirements............................................................................ 10

5.3 Connecting fibers...................................................................................... 10

5.4 Mounting/removing the sensor............................................................... 11

5.5 Ambient temperature............................................................................... 12

5.6 Alignment.................................................................................................. 12

6 Electrical installation........................................................................ 13

6.1 Notes on UL approval............................................................................... 13

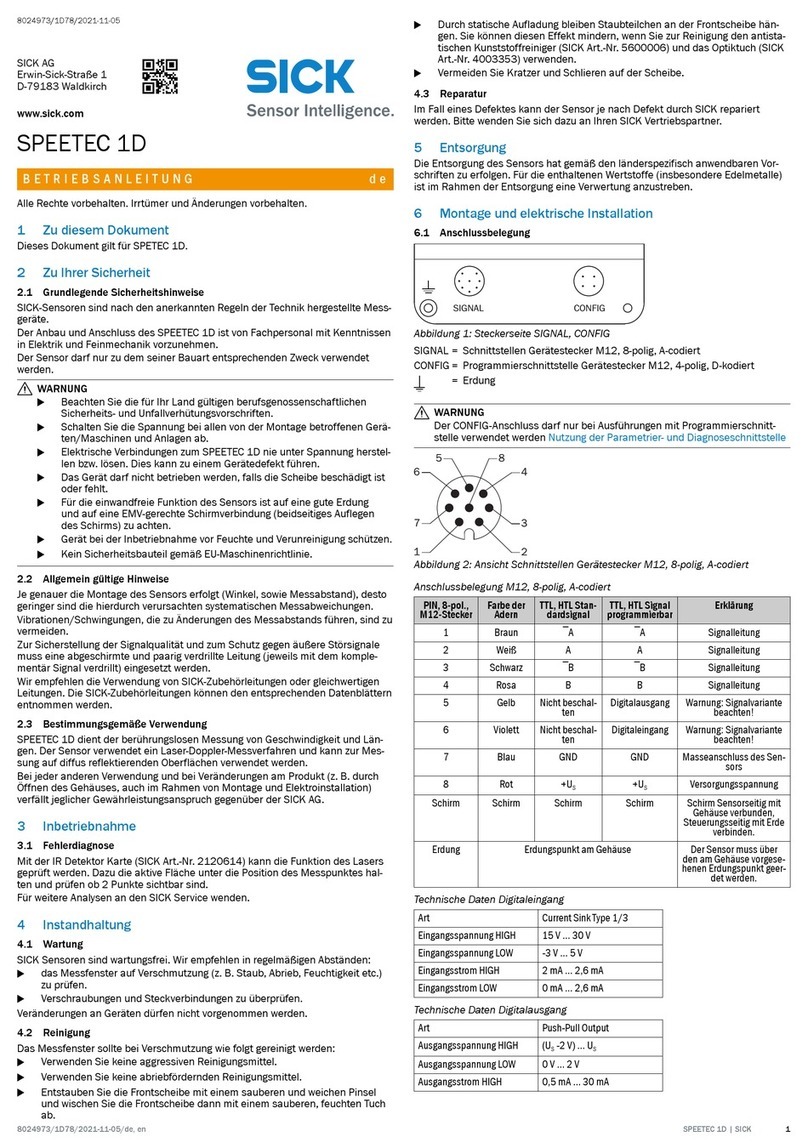

6.2 Connections.............................................................................................. 14

6.3 Multifunction input/output....................................................................... 15

6.4 Wiring the digital input............................................................................. 15

6.5 Wiring the digital outputs......................................................................... 15

7 Commissioning.................................................................................. 17

7.1 YouTube videos......................................................................................... 17

7.2 Initial menu settings................................................................................. 17

7.3 Setting the sensing range/switching threshold/current or voltage

range/teach-in.......................................................................................... 18

8 Operation............................................................................................ 21

8.1 Control elements...................................................................................... 21

8.2 General sensor functions......................................................................... 22

8.3 Main menu navigation tree (1st menu level).......................................... 24

8.4 Default settings (1st menu level)............................................................ 25

8.5 Display settings......................................................................................... 27

8.6 Time functions.......................................................................................... 30

8.7 Detection parameters............................................................................... 33

8.8 I/O settings............................................................................................... 39

8.9 Device information.................................................................................... 45

8.10 Analog channel settings........................................................................... 47

8.11 Initializing the device................................................................................ 50

CONTENTS

8027947 /2022-12-14 | SICK O P E R A T I N G I N S T R U C T I O N S | WLL80 Analog 3

Subject to change without notice