SICK HTE18 Series User manual

Other SICK Accessories manuals

SICK

SICK WLA26 00 Series User manual

SICK

SICK PowerProx Mini WTT4SLC User manual

SICK

SICK UM12 Series User manual

SICK

SICK KTS User manual

SICK

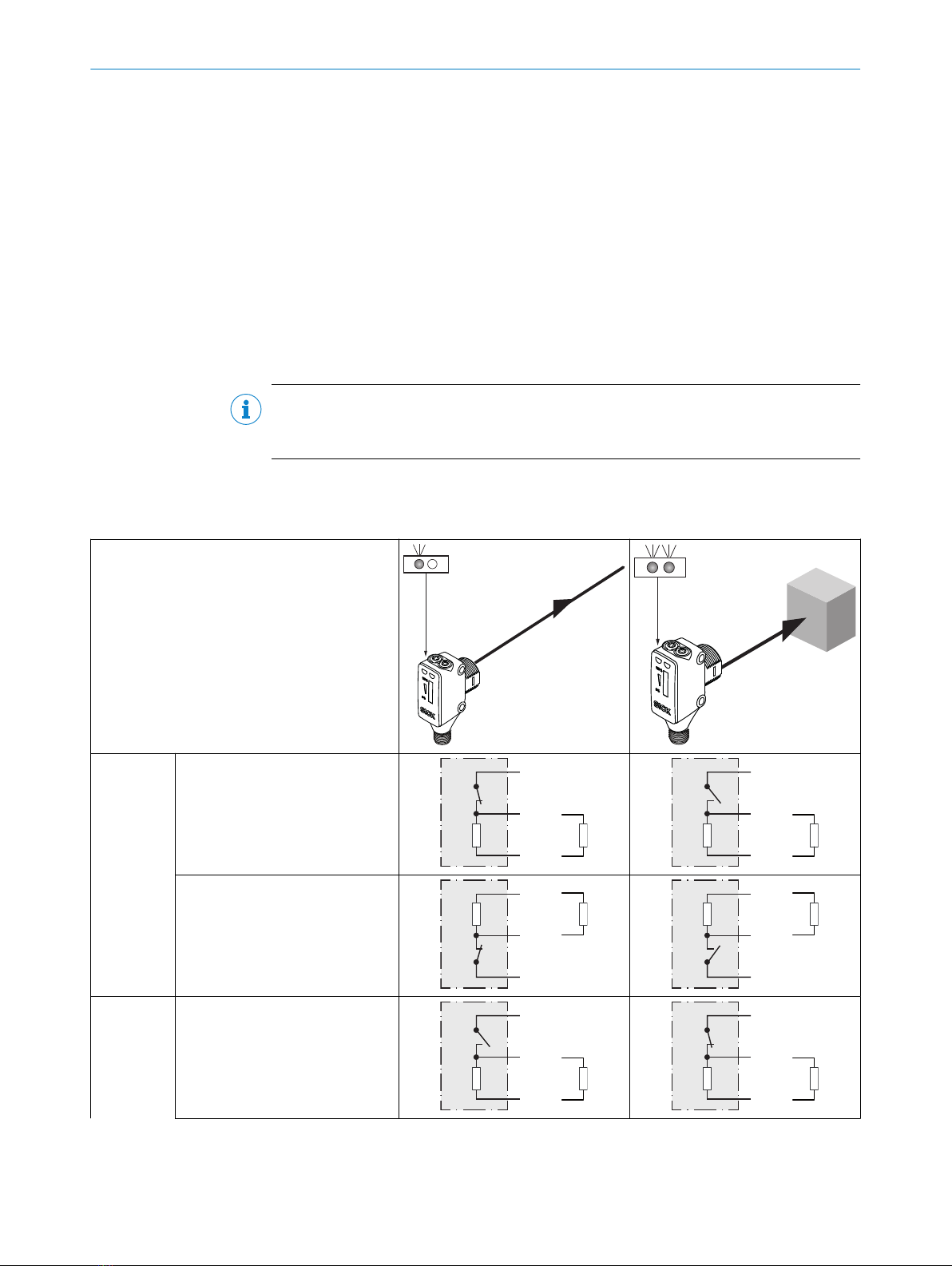

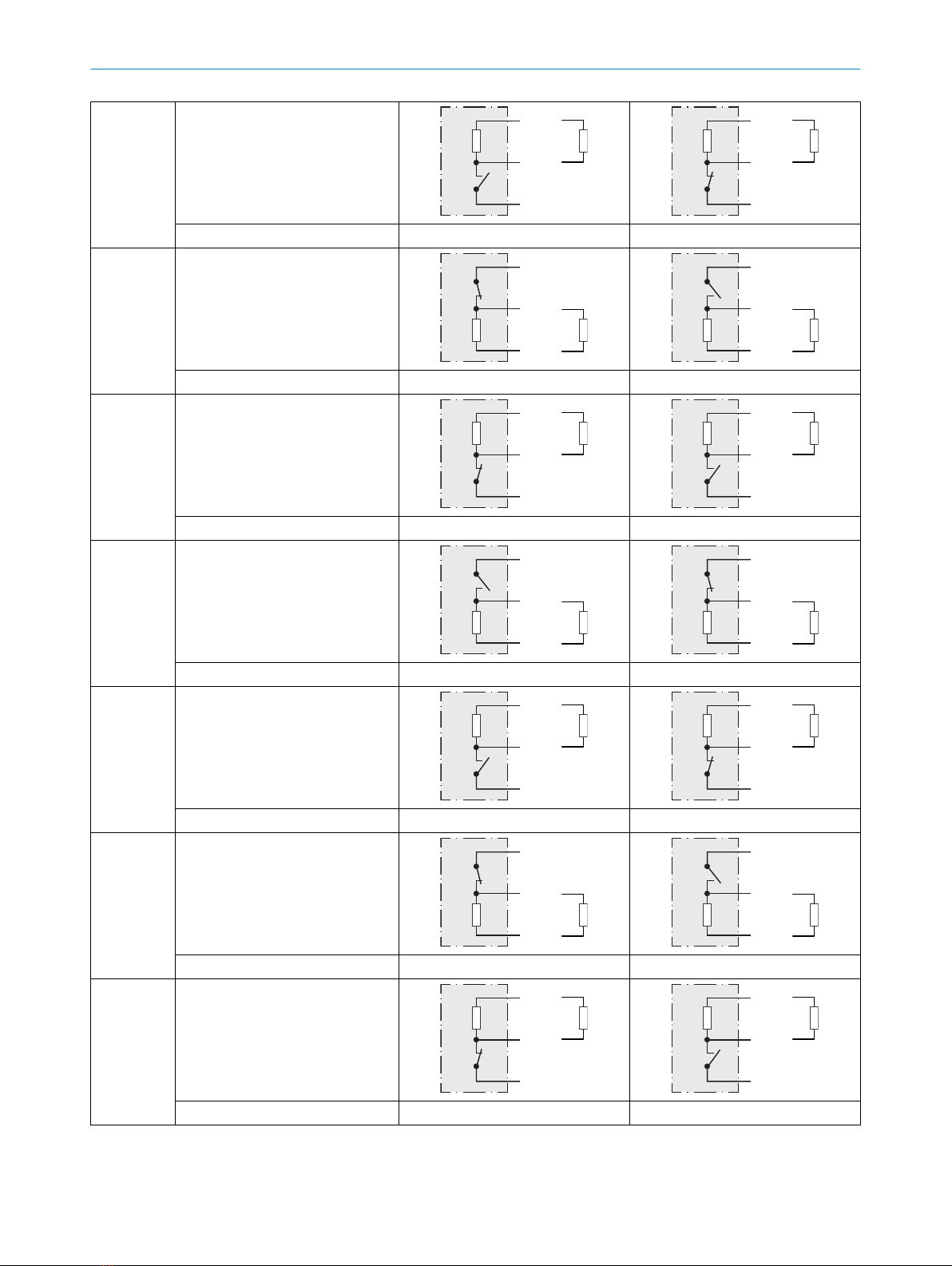

SICK MAX48 User manual

SICK

SICK PowerProx WTT12L User manual

SICK

SICK DT1000 User manual

SICK

SICK LBV 320 User manual

SICK

SICK SIM2000ST User manual

SICK

SICK DL100 Pro User manual

SICK

SICK WLD26 User manual

SICK

SICK DL1000 User manual

SICK

SICK TiM4 Series User manual

SICK

SICK MLS User manual

SICK

SICK SureSense HTF18L User manual

SICK

SICK SureSense HTB18L Series User manual

SICK

SICK CFP CUBIC User manual

SICK

SICK RAY26 User manual

SICK

SICK DT50-2 Pro User manual

SICK

SICK W4F User manual