Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Explanation of symbols............................................................................ 5

1.3 Further information................................................................................... 6

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Improper use............................................................................................. 7

2.4 Cybersecurity............................................................................................ 8

2.5 Limitation of liability................................................................................. 8

2.6 Modifications and conversions................................................................ 8

2.7 Requirements for skilled persons and operating personnel.................. 9

2.8 Operational safety and specific hazards................................................. 9

3 Product description........................................................................... 11

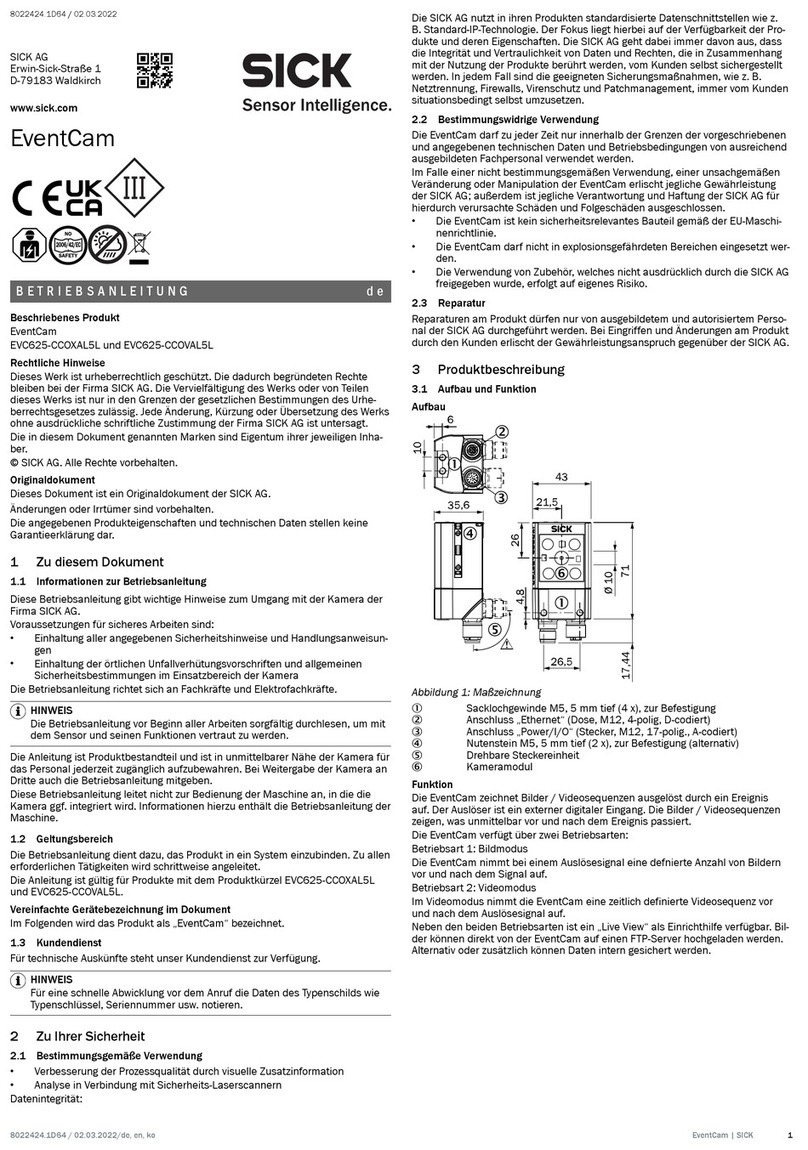

3.1 Device view................................................................................................ 11

3.2 Functionality.............................................................................................. 11

3.3 SICK AppSpace......................................................................................... 11

3.4 Preset Ethernet interfaces....................................................................... 12

4 Transport and storage....................................................................... 13

4.1 Transport................................................................................................... 13

4.2 Transport inspection................................................................................. 13

4.3 Storage...................................................................................................... 13

5 Mounting............................................................................................. 14

5.1 Overview of mounting procedure............................................................. 14

5.2 Scope of delivery....................................................................................... 14

5.3 Preparing for mounting............................................................................. 14

5.4 Mounting the device................................................................................. 14

6 Electrical installation........................................................................ 15

6.1 Important information.............................................................................. 15

6.2 Preparing the electrical installation......................................................... 15

6.3 Overview of connections.......................................................................... 16

6.4 Pin assignment......................................................................................... 16

6.5 Connecting peripheral devices................................................................ 18

6.6 Connecting voltage supply....................................................................... 18

7 Commissioning.................................................................................. 20

7.1 Preparatory commissioning..................................................................... 20

8 Operation............................................................................................ 21

8.1 Status LEDs............................................................................................... 21

CONTENTS

8028935//2023-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | SIM800 3

Subject to change without notice