2PJC211/212/221/222 version 2.0.7 - Sept 2014

DO NOT connect any other control equipment to the S-link controlled products except

Side-Power original S-link products or via a Side-Power supplied interface product made for inter-

facing with other controls. Any attempt to directly control or at all connect into the S-link control

system without the designated and approved interface, will render all warranties and responsi-

bilities for the complete line of Side-Power products connected void and null. If you are interfac-

ing by agreement with Sleipner and through a designated and approved interface, you are still

required to also install an original Sidepower control panel to enable efcient troubleshooting if

necessary

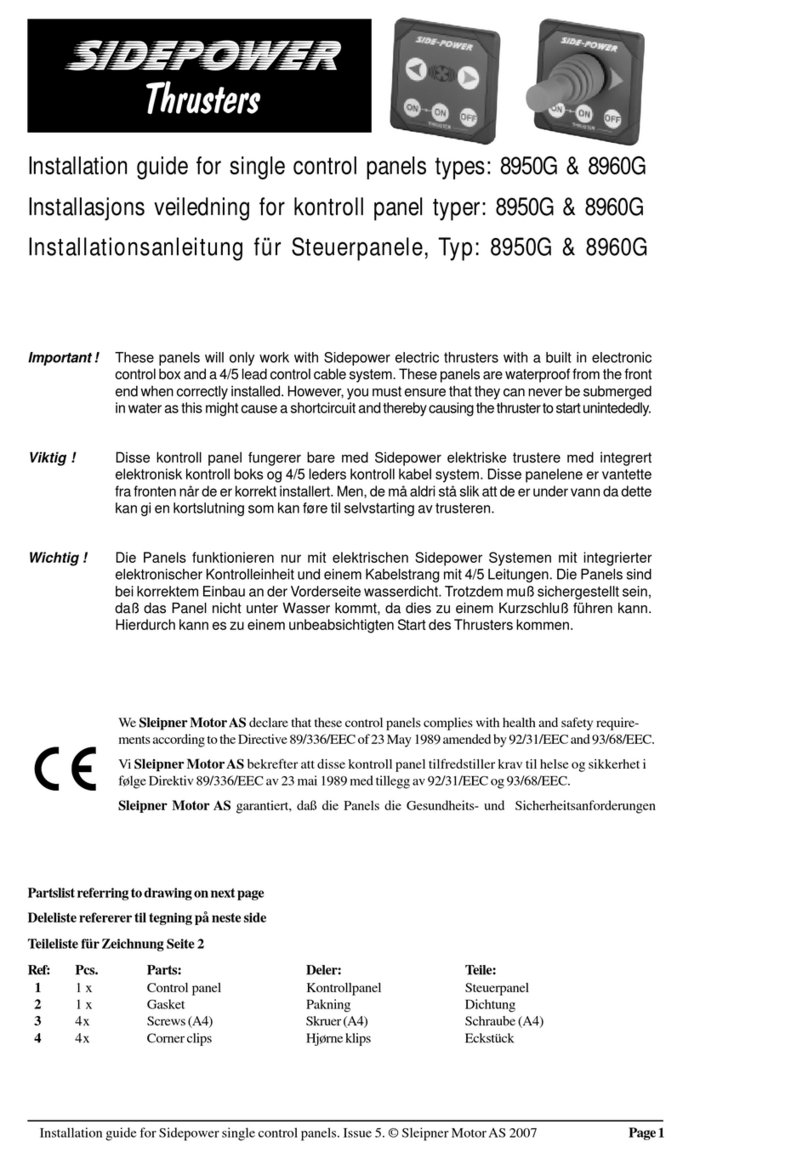

DECLARATION OF CONFORMITY

We, Sleipner Motor AS

P.O. Box 519

N-1612 Fredrikstad, Norway

declare that this product with accompanying standard remote

control systems complies with the essential health and safety

requirements according to the Directive 89/336/EEC of 23

May 1989 amended by 92/31/EEC and

93/68/EEC.

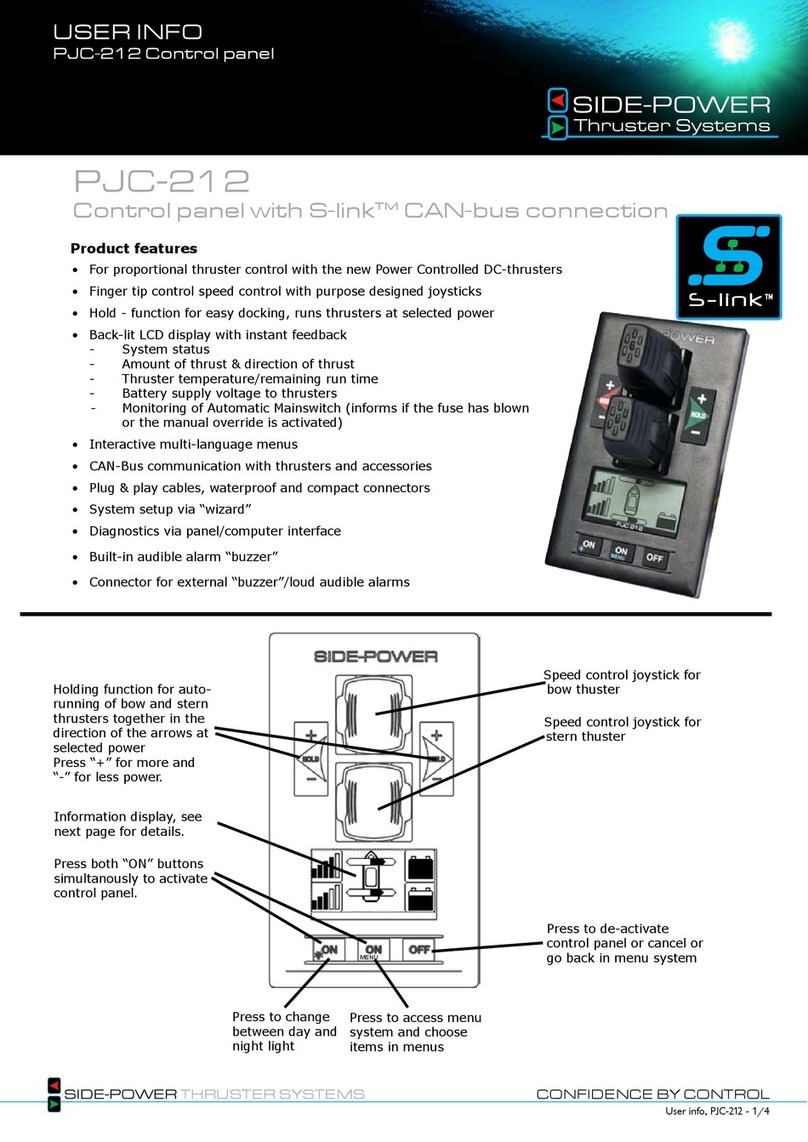

Product Features ..............................................................................................................................................................................................3

Panel layout & functions ............................................................................................................................................................................. 4-5

Display in normal use .....................................................................................................................................................................................6

symbols explanations.................................................................................................................................................................................. 7-8

Alarm DC system .............................................................................................................................................................................................9

Alarms ( AC and hydraulic thrusters )......................................................................................................................................................... 10

Menu system ................................................................................................................................................................................................. 11

Menu system - Language - Stabilizer - default settings ........................................................................................................................... 12

Setup procedure........................................................................................................................................................................................... 13

Menu system - Setup...............................................................................................................................................................................14-19

System devices ...................................................................................................................................................................................... 14

1. PHC 024 .................................................................................................................................................................................. 14

2. PDC 201 .................................................................................................................................................................................. 17

3. PDC 101 .................................................................................................................................................................................. 17

4. MAIN SWITCH ........................................................................................................................................................................ 18

5. PPC800, SR150 000, SR61242.........................................................................................................................................18-19

6. RCRS-1..................................................................................................................................................................................... 20

7. MSI8730 .................................................................................................................................................................................. 20

Hold calibration ..................................................................................................................................................................................... 21

Menu system - Info........................................................................................................................................................................................ 22

Menu system - Panel Setup.......................................................................................................................................................................... 23

Alarm descriptions ..................................................................................................................................................................................24-25

Technical specications................................................................................................................................................................................ 26

S-link system example.................................................................................................................................................................................. 27

Measurements............................................................................................................................................................................................... 28

Connections .................................................................................................................................................................................................. 29

Notes .........................................................................................................................................................................................................30-31

Contents