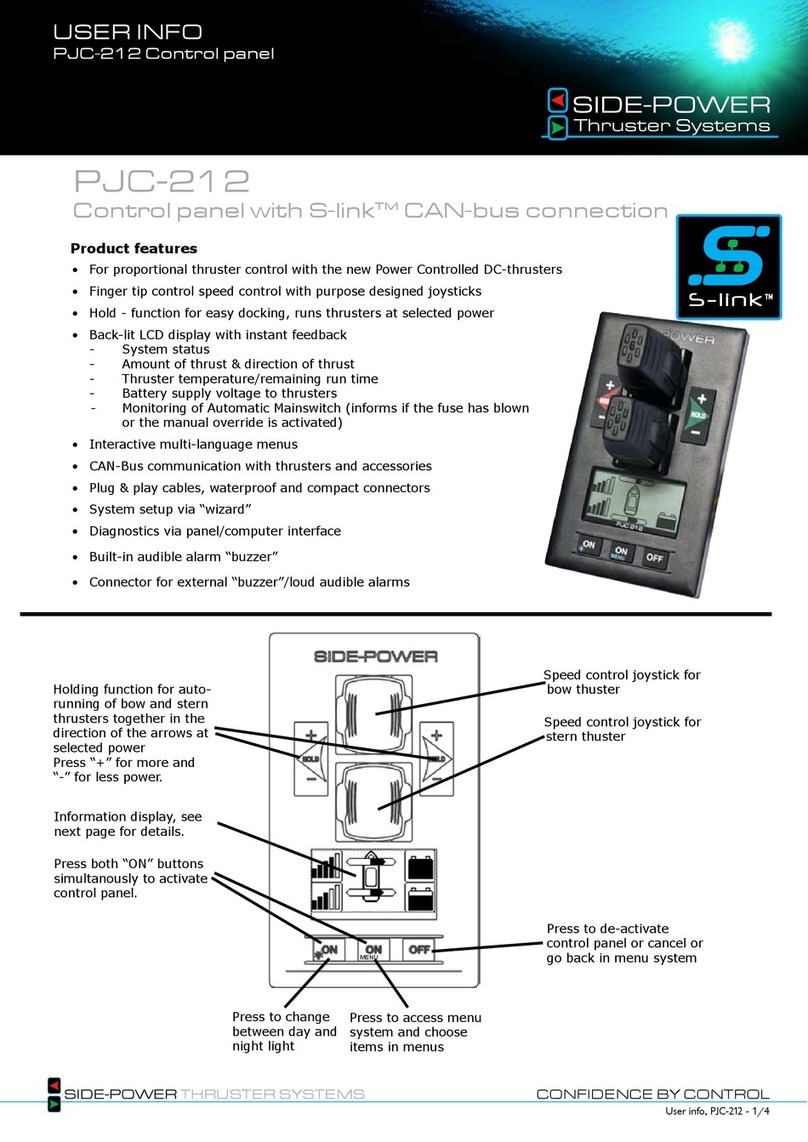

Battery indicator.

From 8.5V to 12V for 12V thrusters,

15V to 24V for 24V thrusters

Motor temperature indicator.

From 70°C to 130°C

INDICATORS FOR DC Thrusters:

INDICATORS FOR AC Thrusters:

INDICATORS FOR Hydraulic Thrusters:

Motor temperature indicator.

Hydraulic oil temperature indicator.

INDICATORS FOR Retractable Thrusters:

Symbol shown when the thruster deploys

Symbol shown when the thruster retracts

Symbol shown when the thruster is in

position OUT

When the thruster is deployed and no

input is given via the joysticks/buttons

over a 10 second period, the panel will

give a audible signal every 10th second

to tell that the truster is still deployed.

Thrust power and direction, Bow thruster(s)

Input from bow joystick on this panel.

The thrust indicator will be shown in this position on a single

joystick panel if the thruster is dened as a bow thruster

Indicating amount of thrust set by other control units in the

system, i.e additonal PJC panels, 8700 Retract panel, input

via 8730 S-link external switch interface, S-link remote con-

trol etc.

If two or more units is set to run the thruster in

opposite direction, this information will not be shown.

FIRST TIME SETUP

After installation of a S-link thrusters system, a System Setup procedure to setup control panels, thrusters and

additional equipment must be completed (ref. procedure on page 10) before the system can be used.

Thrust power and direction, Stern thruster(s)

Input from stern joystick on this panel

The thrust indicator will be shown in this position on a single

joystick panel if the thruster is dened as a stern thruster.

Battery indicator.

From 8.5V to 12V for 12V thrusters,

15V to 24V for 24V thrusters

Motor temperature indicator.

From 70°C to 130°C

Symbol shown when a DC Thruster is

used in a dual bow or dual stern setup:

INDICATORS showing thrust direction and amount: