GAMMA instabus

Technical product information

July 2008

Switching actuator, submodule N 512/21 5WG1 512-1AB21

3x AC 230/400V, 16A, C-load, load-check

Siemens AG N 512/21, 4 pages Technical manual

Industry Sector, Building Technologies

Electrical Installation Technology © Siemens AG 2008 Update: http://www.siemens.com/gamma

P.O. Box 10 09 53, D-93009 Regensburg Subject to change without further notice

2.4.3.3/1

Product and functional description

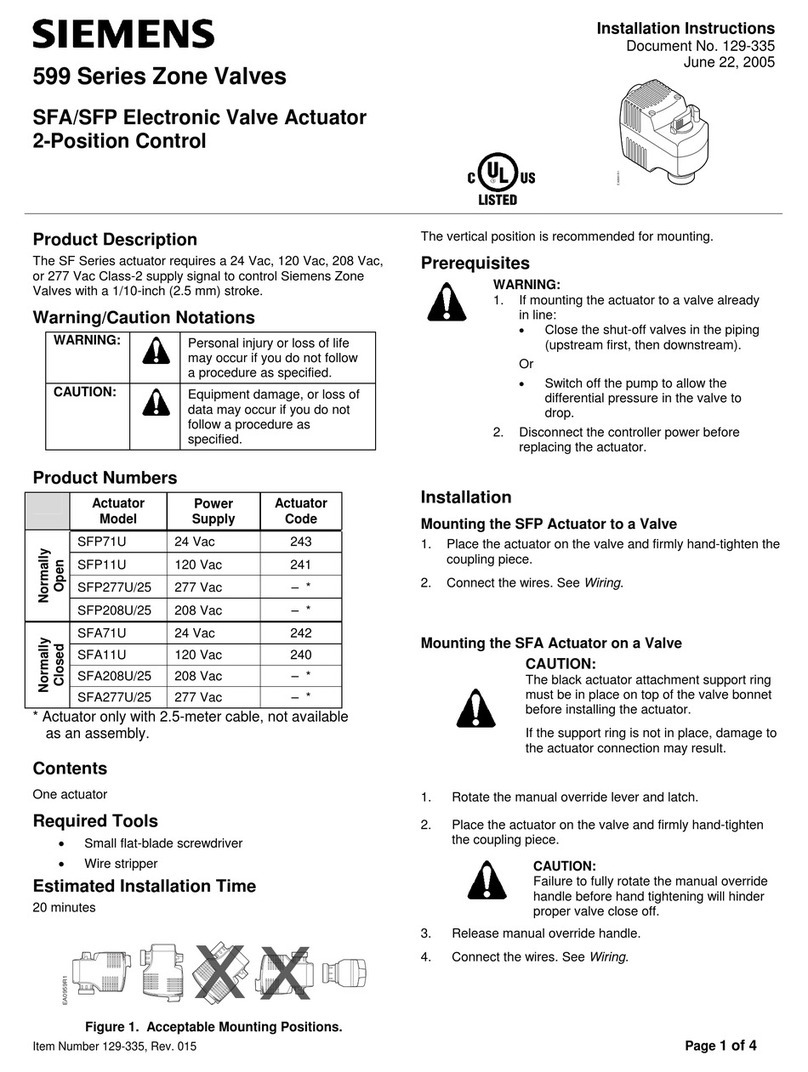

The switching actuator submodule N 512/21 is a 3 MU

(module units) wide device for DIN-rail mounting in N-

system dimensions, with 3 switching outputs (relay con-

tacts) for AC 230/400V, 16A, C-load, each with load cur-

rent measurement and monitoring (load-check). A sub-

module cannot be operated stand-alone or be directly

connected to the bus. But it can be connected via a spe-

cial 6-pole bridging connector either with a switching

actuator main module or with another submodule which

is already connected to a main module (see figure 1).

The submodule electronics are supplied by bus voltage

via the 6-pole bridging connector.

In total up to 4 switching actuator submodules can be

connected in series to a switching actuator main module,

so that a main module, if need be, can be extended sim-

ply from a 3-fold to a 6-, 9-, 12- or 15-fold switching

actuator and thus be matched flexibly to the number of

loads to be switched.

It is indicated by flashing of the corresponding green LED

A to E on the top of the main module if more sub-

modules are set than are actually connected or if the set

submodule type does not correspond with the sub-

module type actually connected or if a submodule is

detected as faulty.

Behavior in case of mains failure / recovery

Because the electronics of a submodule are fed from the

bus (via the 6-pole interface to the main module), a

mains failure then leads solely to a failure of the sub-

module if the bus voltage also fails as the result of a

mains failure. However, it can be set for each submodule

output individually which switching state it is to assume

on a bus voltage failure and after the bus voltage recov-

ery: as before bus voltage failure, ON or OFF.

Application program

The N 512/11 switching actuator needs the application

program "07B0 A15 Switching Actuator 981B01". This

controls the outputs of the main module as well as the

outputs of all connected submodules via their 6-pole

interface.

In bus mode, a communication object can be available

for each actuator output - for switching, for manual

override, for a forced control, for a logical combination

and for status query. Furthermore, if required, time-

limited switching instead of permanent switching on can

be enabled for each channel via an optional "Night

mode" object (e.g. for lighting while cleaning), if need be

with a warning before switching off by multiple switch-

ing the output on and off (flashing). It can also be se-

lected whether all a module's outputs are to be set jointly

and thus identically or whether each output is to be set

separately and individually.

Amongst others, the application program includes op-

tional detection and monitoring of the load current for

each output on load failure and/or overload, simultane-

ous switching of all 3 outputs (3-phase switching), con-

version of a speed given as a percentage value into 1- to

3-stage switching commands (fan speed control), con-

version of a valve setting given as a percentage value

into a pulse width modulated (PWM) switching com-

mand (thermal drive control), a switching cycle and

operating hours count with threshold monitoring for

each output and an integrated 8-bit scene control, in

which each output can be incorporated into up to 8 sce-

nes.

To load the application program, the Engineering Tool

Software (ETS) is required as version 3.0 f or higher.

Note: If the N 512/11 application program is "unloaded"

with the ETS, then you will no longer be able to activate

direct mode, i.e. the LED status display and local switch-

ing of the outputs using the buttons on the front panel

of the actuator are disabled. Only after reloading the

application program can you re-enable the status display

and direct mode.