Document No. 129-253

Installation Instructions

August 2, 2007

Page 2 of 4 Siemens Building Technologies, Inc.

Installation

If you are mounting an actuator on a new valve, begin with

the instructions Mounting an Actuator on a Valve.

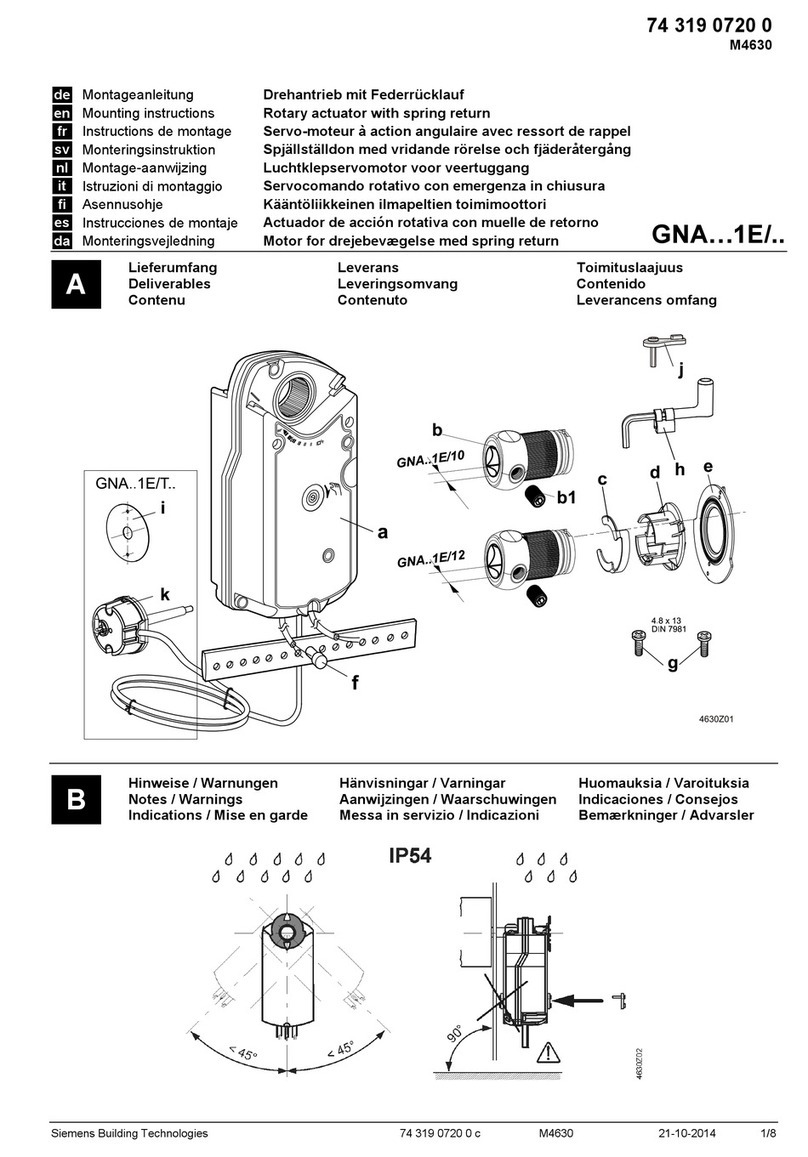

Removing the actuator from a valve

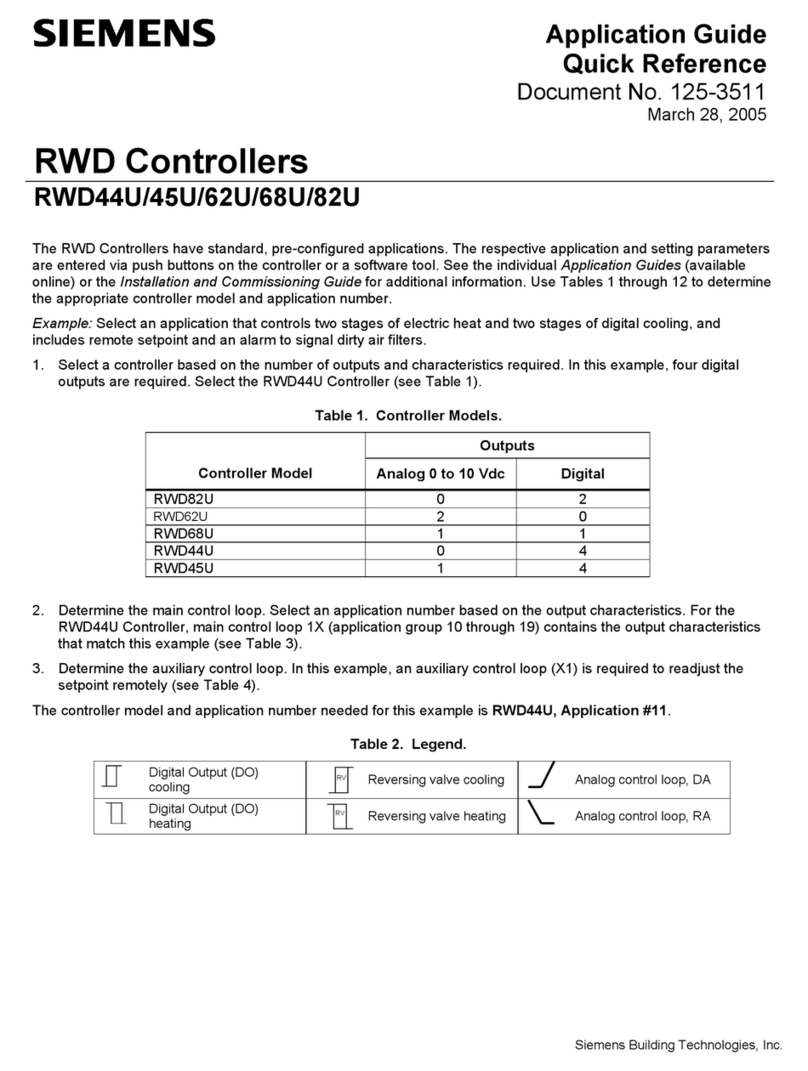

1. Remove the terminal cover (Figure 2) using a Phillips

head screwdriver,

2. Identify and disconnect wiring from the terminals.

3. Remove wiring retention screw.

4. Do one of the following:

•Remove plenum cable adapter and plenum

cable; or

•Remove flex conduit.

5. Loosen the actuator coupling on the valve (Figure 3,

reverse #2).

6. Remove the actuator from the valve.

EA1154R1

WIRING TERMINAL

WITH REMOVABLE

TERMINAL BLOCK

TERMINAL

COVER

AND SCREWS

FLEX

CONDUIT

ADAPTER

PLENUM CABLE

ADAPTER

(OPTIONAL USE)

WIRING

RETENTION

SCREW

Figure 2. SSC Actuator Components.

Mounting an Actuator on a Valve

1. If you are attaching the actuator to a new valve,

remove the protective plastic cap from the valve

stem.

2. Turn the manual position indicator on the top of the

actuator to the 0 position (Figure 10).

3. Using a Phillips head screwdriver, remove the

terminal cover (Figure 2).

4. Remove wiring retention screw.

5. Remove plenum cable adapter.

6. For plenum applications, complete wiring as follows:

a. Route cable through plenum cable adapter so

there is sufficient cable to complete wiring

terminations.

b. Insert plenum cable adapter into flex conduit

adapter and secure in place with wiring retention

screw.

NOTE: Insert wiring retention screw in hole farthest from

wiring terminals. (The hole nearest the wiring

terminals is to secure the terminal cover in

place.)

c. Continue with Step 8.

7. For 3/8-inch flex conduit applications, complete

wiring as follows:

a. Discard plenum cable adapter.

b. Insert flex conduit into flex conduit adapter and

secure in place with wiring retention screw.

NOTE: Insert wiring retention screw in hole

farthest from wiring terminals. (The

hole nearest the wiring terminals is

to secure the terminal cover in

place.)

c. Route wiring through flex conduit for wiring

terminations.

8. Connect wires to wiring terminals per the Wiring

section of this document.

9. Secure the terminal cover in place over the wiring

terminals (Figure 2) using a Phillips head

screwdriver,

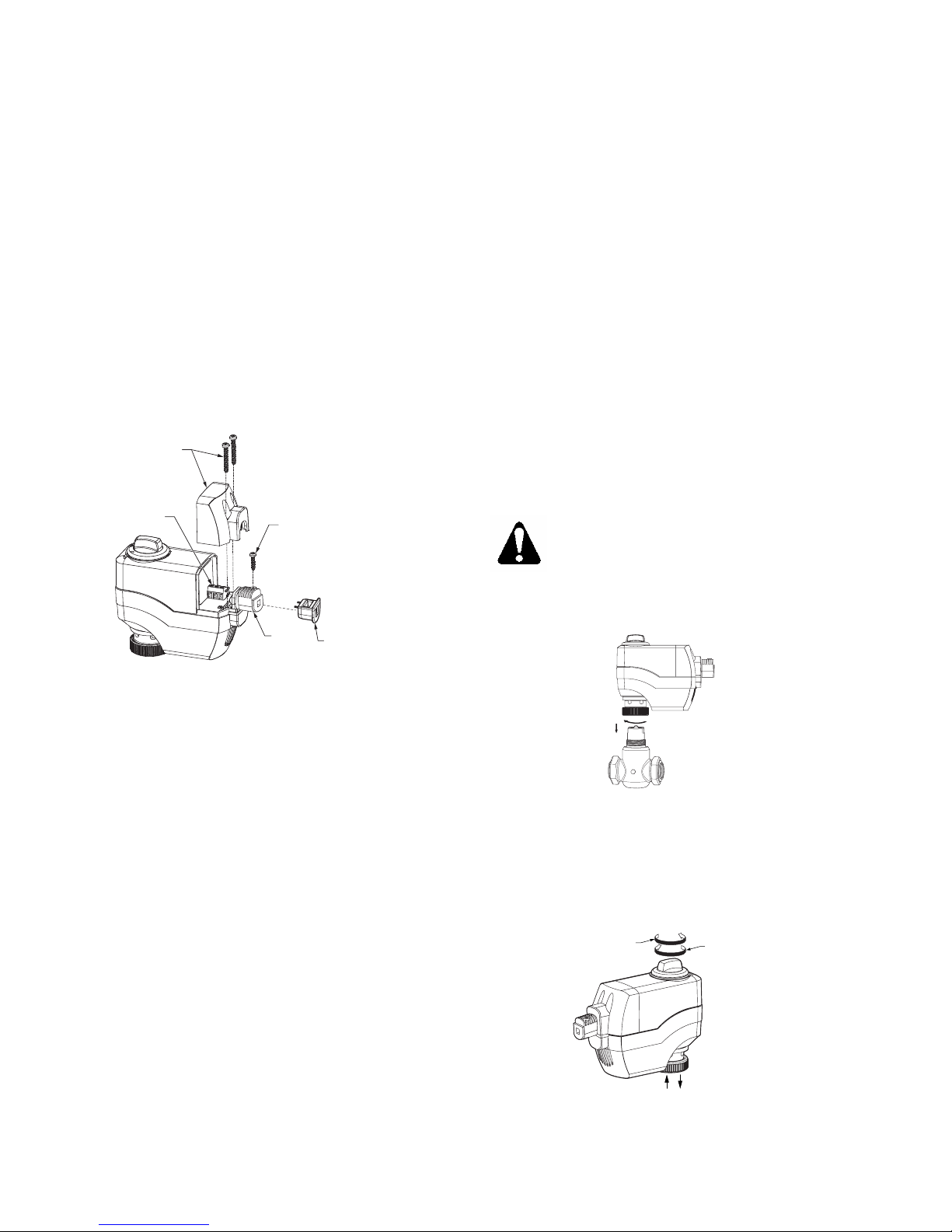

10. Place the actuator on the valve and firmly hand-

tighten (Figure 3).

CAUTION:

Hand-tighten the actuator to the valve. The

use of tools to tighten the assembly together,

will cause damage.

The installation is complete.

EA1160R1

1

2

Figure 3. Coupling Actuator to Valve.

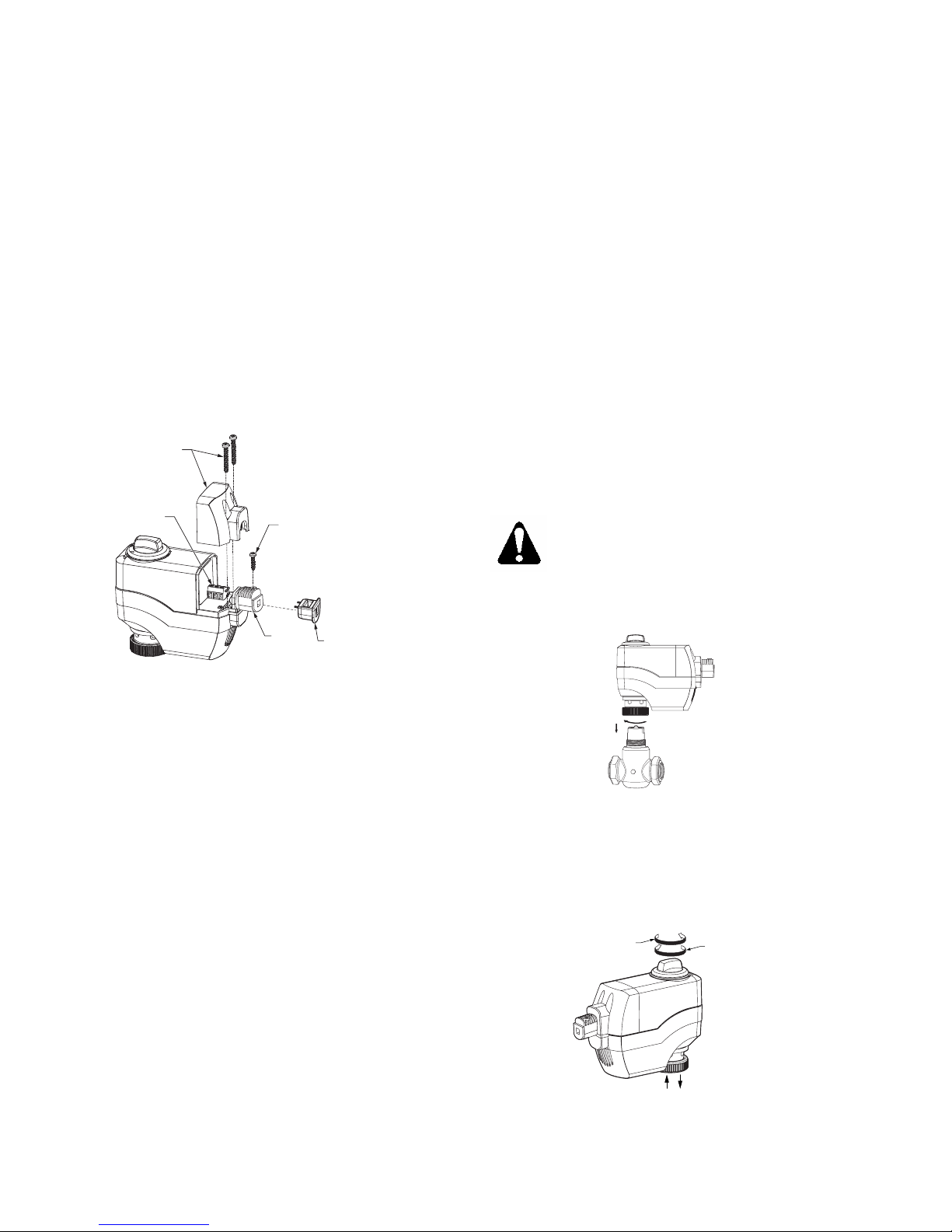

Manual Override

To position the actuator manually, use the manual override

knob in the center of the position indicator (Figure 4).

CLOCKWISE

EXTENDS

SHAFT

COUNTER

CLOCKWISE

RETRACTS

SHAFT

EA1161R1

A

B

AB

Figure 4. Manual Override.