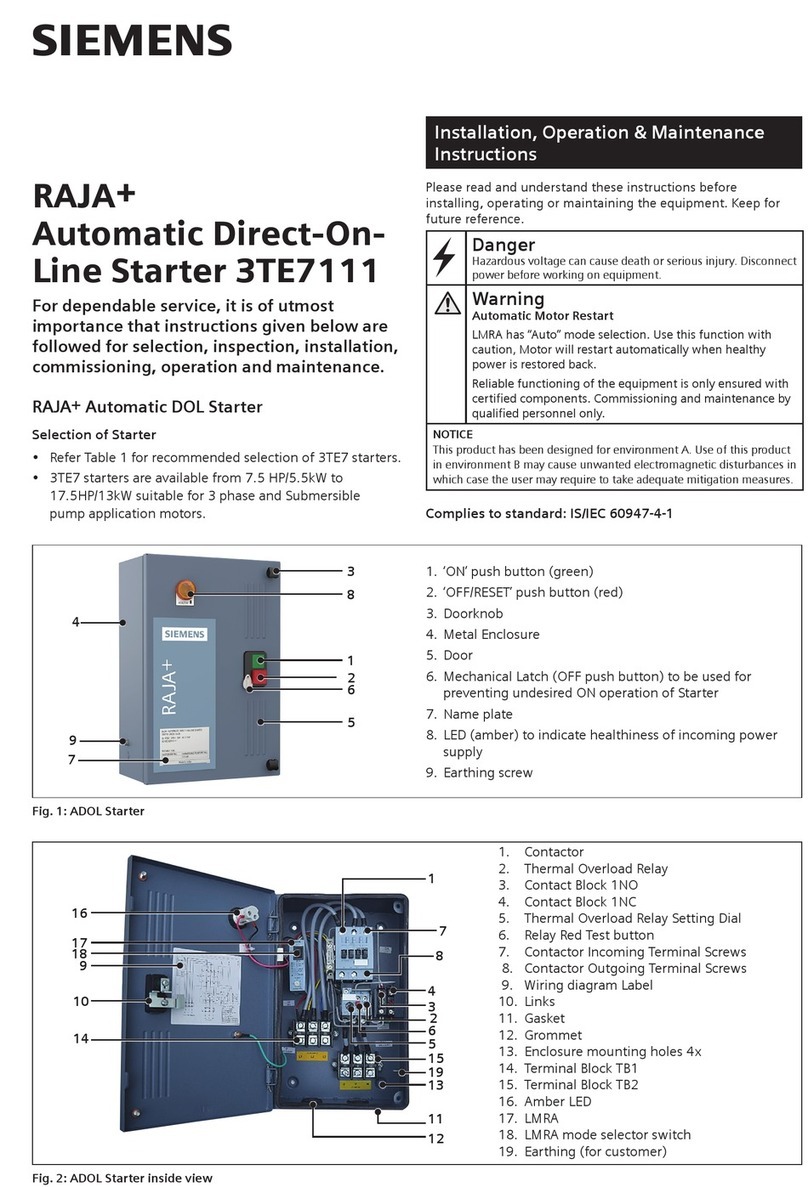

Installation:

• Openthedoorbyrotatingthedoorlocksanticlockwise.

• Mountthecontrolleronaverticalwall/platefreefrom

vibrationswithpropernutsandbolts.ReferFig.6for

mountingdimensions.

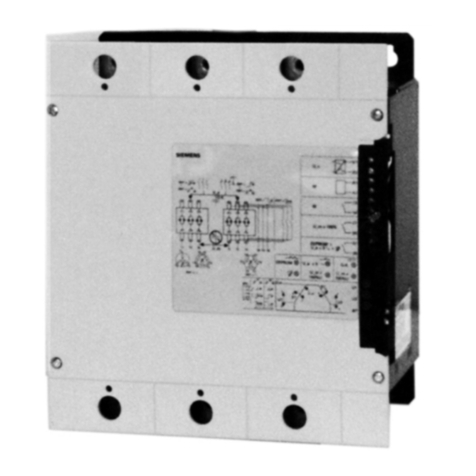

• Removetherubbergrommetsfortheincomingand

outgoingcableconnections.(ReferFig.2)

• Connectincomingandoutgoingcablesasfollows(Refer

Fig.2):

– Usepropercableglandstoensuredustproong.For

conduitentryusepackedwashers.

– SelectcorrectsizeofcablesfromTable1.

– Connectlineandmotorcablesexactlyasperwiring

diagrampastedinsidethecoverofthecontroller.

– Terminatetheincomingsupplycablesonterminal

blockTB1&outgoingcablestomotoronterminal

blockTB2,TB3(Tighteningtorque-Refertable2).

NOTE:LMRAissetinManualmode(Factorysetting)

WLCissetinDeliverymode(Factorysetting)

– Connecttheearthingconductortoterminalsmarked

(earth)onthecontrollerbodywithtorque1.2to

1.6Nm.

TheControllerisnowreadyforcommissioning.

• Initiallysettheoverloadrelayto0.58timestherated

motorcurrent.

• Setthetimerdialtothenearestvalueofstartingtime

availableonmotornameplate.

Ifitisnotavailable,thensetthedialtoapproximately

6-8secs.

• Closethedoorbyrotatingthedoorlocksclockwise.

Commissioning:

Forexactsettingoftimerandoverloadrelay,followthe

instructiongivenbelow:

Before switching ON recheck all external connections.

• Star-DeltaTimersettingforFASDController:

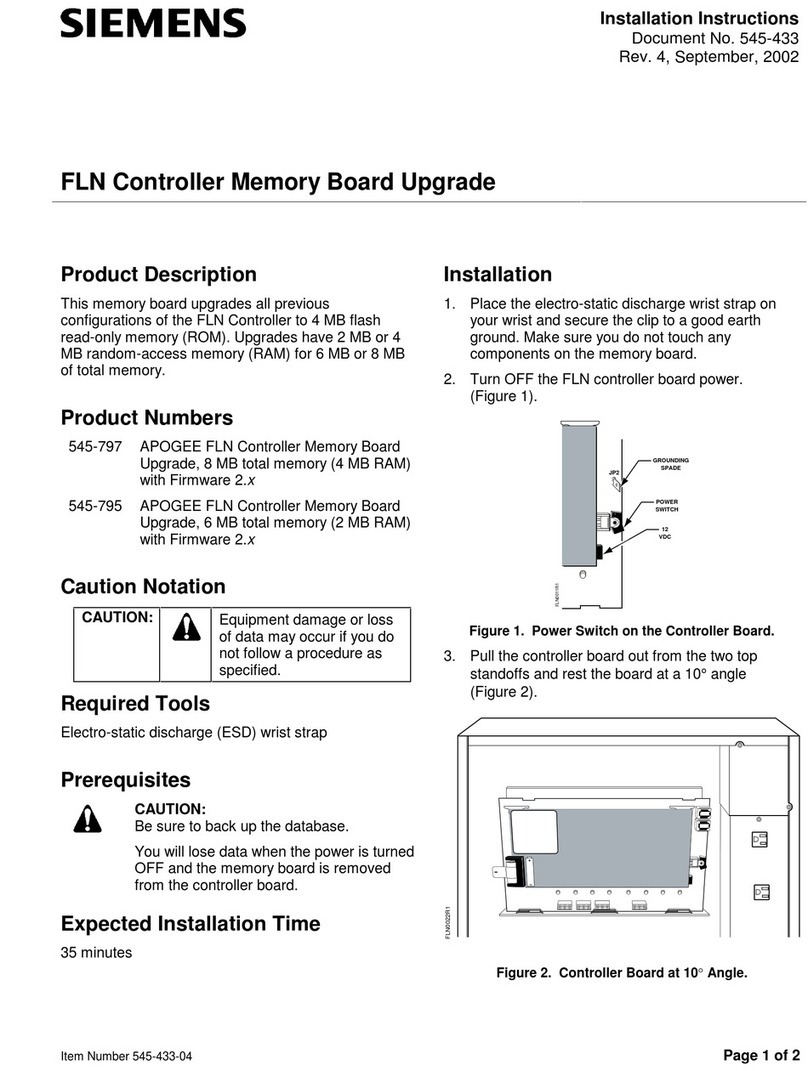

– FirstSwitchONtheRockerswitch(ControlOn/Off).

– Startthemotorbypressingthe‘ON’buttonshownin

Fig.1.

– Measurethetimetakenbythemotortonearly

reachratedspeedorsteadystatecurrentcondition

(indicatedwhenthemotorreachesasteadyhum).

– StopthemotorbyOFFbuttonshowning.1.

– Openthedoor&Setthetimertothismeasuredvalue

byrotatingthedialshowninFig.3.

• Overloadrelaysetting:

– Forcloserprotectionsettheoverloadrelaytoactual

phasecurrentasmeasuredbyanammeter.Inthe

absenceofanammeter,usetheproceduregiven

below:

– Startthemotorandletitrunfor30mins.Then

graduallyreducetherelaysettingstillittrips.Setthe

relayataslightlyhighervaluethanthissetting.

Overloadrelaycharacteristics(Referservicemanual

A5E50797230A)canbeusedtoestimatetheaverage

trippingtimeatdifferentmultiplesofsetcurrent.

– Allowaresettimeofapprox.4min.beforepressing

theblueknobontherelaytoresetit.

– Restartthemotoraftersometime.Iftherelaydoes

nottripthenconsiderittobeproperlyset.Ifthe

relaytrips,setatalittlehighervaluethanbeforeand

recheck.

• Closethefrontdoor.

Caution:

• During commissioning or maintenance always ensure

that the main supply is disconnected by switching off

the main switch & Rocker switch.

• InthecaseofFASDcontrollersunderno

circumstances should the relay be set higher than the

phase current i.e. 0.58 times the rated current on the

motor name plate.

• Iftherelaytripsevenwhensetatratedmotorcurrent

thesuitabilityofthecontroller/relayfortheparticular

applicationshouldbecheckedwiththenearestSiemens

office.

Procedure for connecting WLC sensors & terminations:

• ThesesensorsneedtoberoutedfromleftsideofBaseplatethroughcablegland(Pleaseensureduecaretoavoid

damagetothesensors.)

Mode For Single Tank application

(Delivery or Suction mode)

For Dual Tank application

(Dual tank mode) For by passing WLC

ConnectionProcedure ConnectsensorsP1,P2&P3

toTerminalX1,X2,X3of

TerminalblockTB5

ConnectsensorsP1,P2&

P3toTerminalX1,X2,X3of

TerminalblockTB5&sensors

P4,P5&P6toTerminalX4,

X5,X6ofTerminalblockTB5

Removeconnectionbetween

X7-X8ofTerminalblockTB5.

RemoveconnectionfromX11

ofTB5&ConnectittoX12of

TB5.

2

Fig. 3 Timer Adjustment

Dial