Installation Instructions

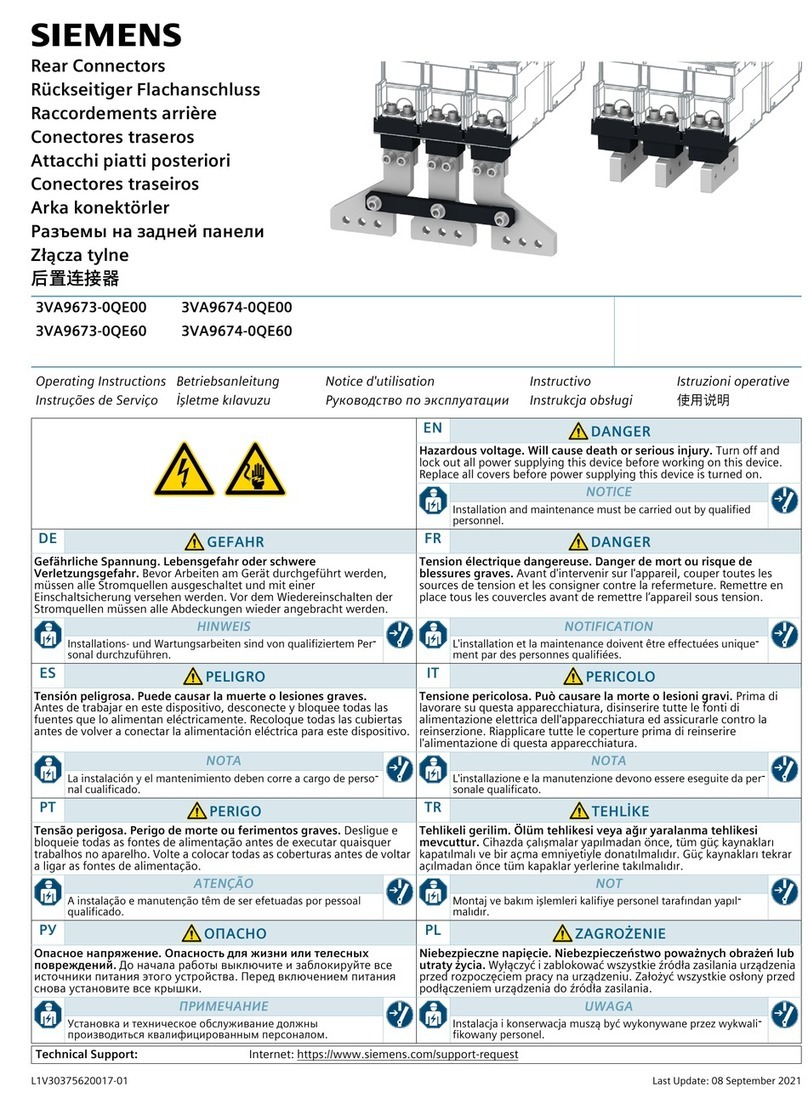

The following instructions are for the installation of Siemens strap kit S3VA55TD in a Distribution Switchboard or P5 Power

Panel. It is for use with a Siemens Type 3VA55 (MMAS, HMAS or CMAS) or Type 3VA65 (MMAE, HMAE or CMAE) breaker

as a Main or Branch device in an 800A application, or Type 3VA66 (MMNAE, HMNAE or CMNAE) breaker as a Main or Branch

device in a 1000A application. The parts provided in this kit connect these breakers to a 1-phase, 2 or 3-wire system or a

3-phase 3 or 4-wire system. This kit requires 8.75” of unit space. Breaker kit can be installed as shown or rotated 180°. (If

rotated, interchange A-phase and C-phase references in the assembly instructions.)

NOTE: The breakers and breaker lugs are NOT included in this kit and must be purchased separately.

11-B-1097-01 Rev. 00-3--2-

1. Lock off power supplying this equipment

before working on it.

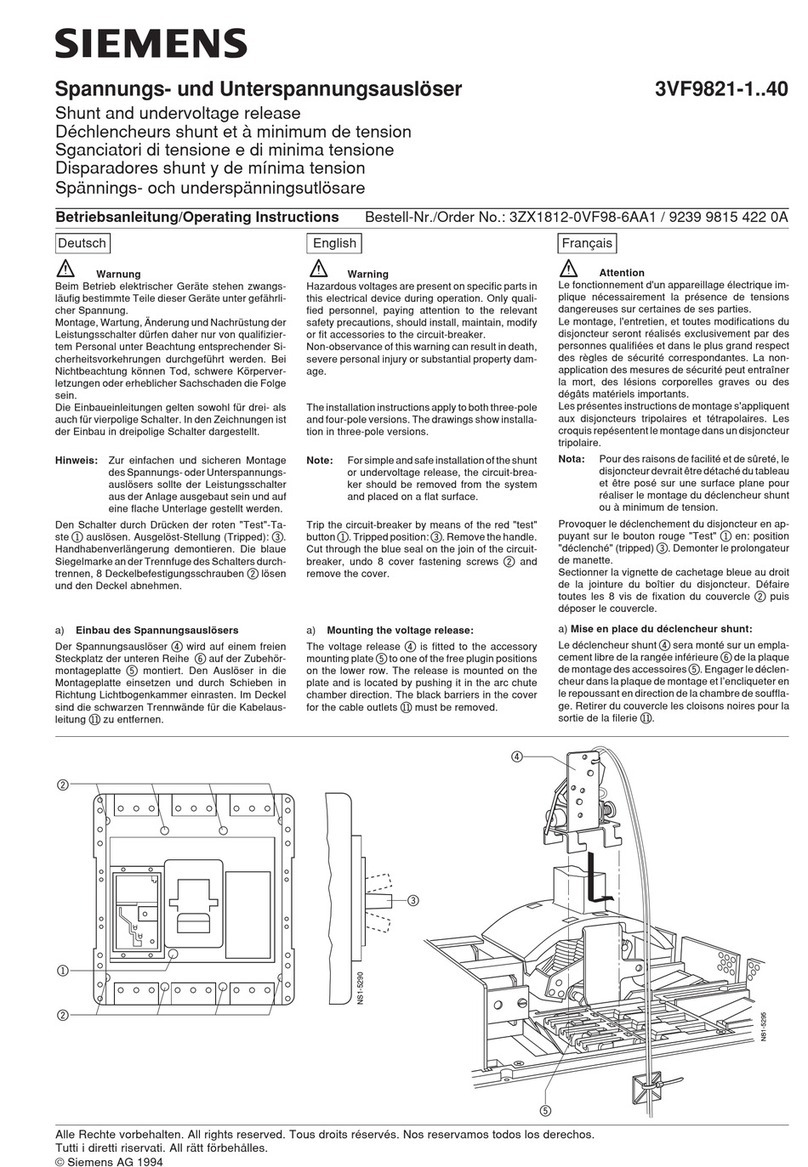

5. Orient one of the Mounting Brackets (Item 1) as

shown and attach it to the Z-rail with two 1/4”-20

screws (Item 19).

3. This kit requires 8.75” of empty unit space.

To locate

the proper mounting position, measure from the top

deadfront support to the top of the empty unit space

filler on the deadfront. Transfer this dimension from

the deadfront support along the Z-rail and mark. This

will be

the unit space (as shown in Figure 3). After

marking the Z-rail, remove the deadfront.

4

.

If an existing branch module occupies the same

location chosen for this kit, remove all of its devices,

components and parts.

INSTALLING THE MOUNTING BRACKETS:

INSTALLING THE SIEMENS BREAKER:

8. Align the Barrier (Item 2) to the Mounting Brackets

(Item 1) as shown and loosely fasten with the four

1/4”-20 tall hex screws (Item 20).

INSTALLING THE BARRIER:

2. Remove the two gutter covers.

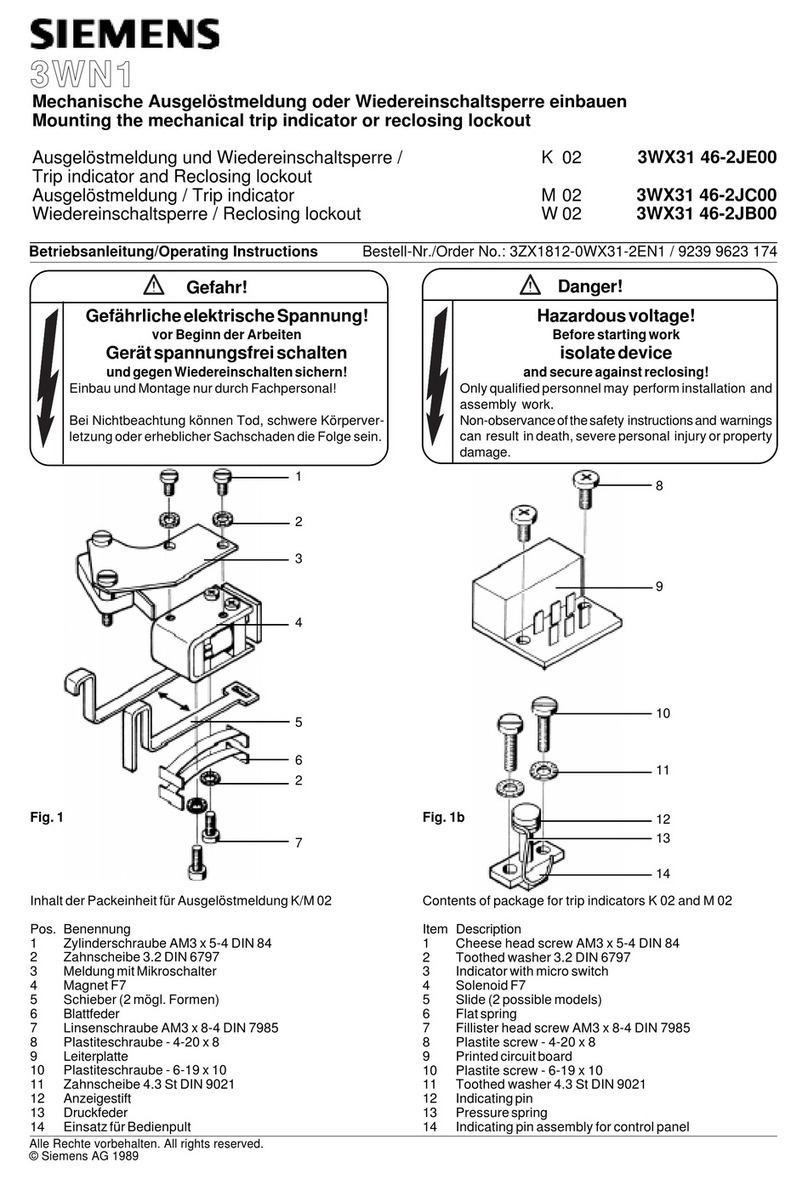

Figure 1

Figure 2

COVER

PLATES

GUTTER

COVERS

Z-RAIL

DEADFRONT

SUPPORTS

DEADFRONT

RAIL (Provision instructions on following page)

6. Repeat for the second Mounting Bracket.

7. Tighten the four screws

to the torque specified on the

rear of the deadfront or noted in the table on this page.

10. To install the

(A-phase) Short Strap (Item 3) and the

(C-phase) Long Strap (Item 5),

locate them as shown,

aligning the holes in the straps to the posts on the

barrier, and loosely attach them to the A and C-phase

bus (respectively) with the four appropriate 1/4”-20

screws from the Bus Hardware Kit (Item 17) each,

thru the straps and into the bus.

11. Tighten all the Barrier and Strap screws

to the torque

specified on the rear of the deadfront or noted in the table

on page 2.

PREPARING THE EQUIPMENT:

9. For three-phase installation ONLY:

(Skip to Step 10 for single-phase systems)

To install the (B-phase) Medium Strap (Item 4), locate

it as

shown, aligning the holes in the strap to the posts

on the barrier, and loosely attach it to the B-phase bus

with the four appropriate 1/4“-20 screws from the Bus

Hardware Kit (Item 17) thru the strap and

into the bus.

INSTALLING THE BREAKER STRAPS:

(Refer to Figures 1, 2 and 3)

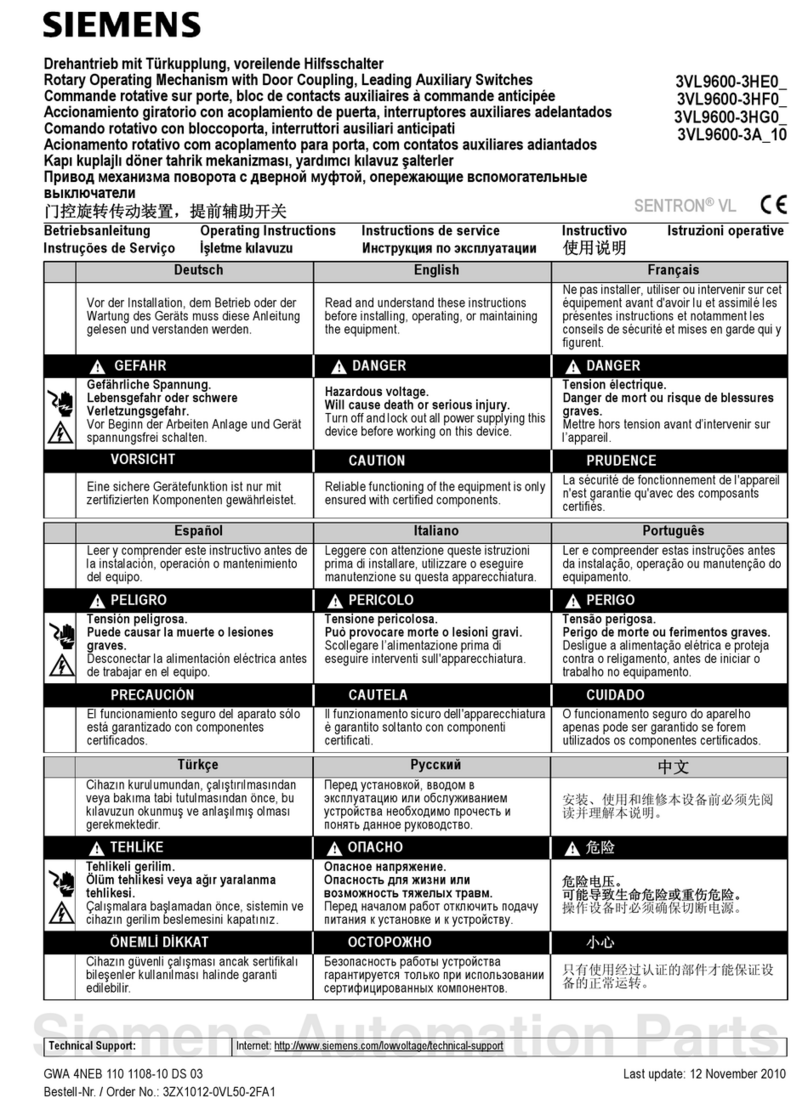

(Refer to Figure 3)

(Refer to Figure 4)

(Refer to Figure 5)

12. Remove the breaker “OFF”-side shield cover and

nut keepers, per the breaker instructions.

13. Install lug kit (NOT INCLUDED) per lug installation

instructions. (Do NOT install lug covers at this time.)

14. Remove the breaker “ON”-side shield cover, and

clip off just enough mesh to clear the straps. (Leave

the nut keepers in place.)

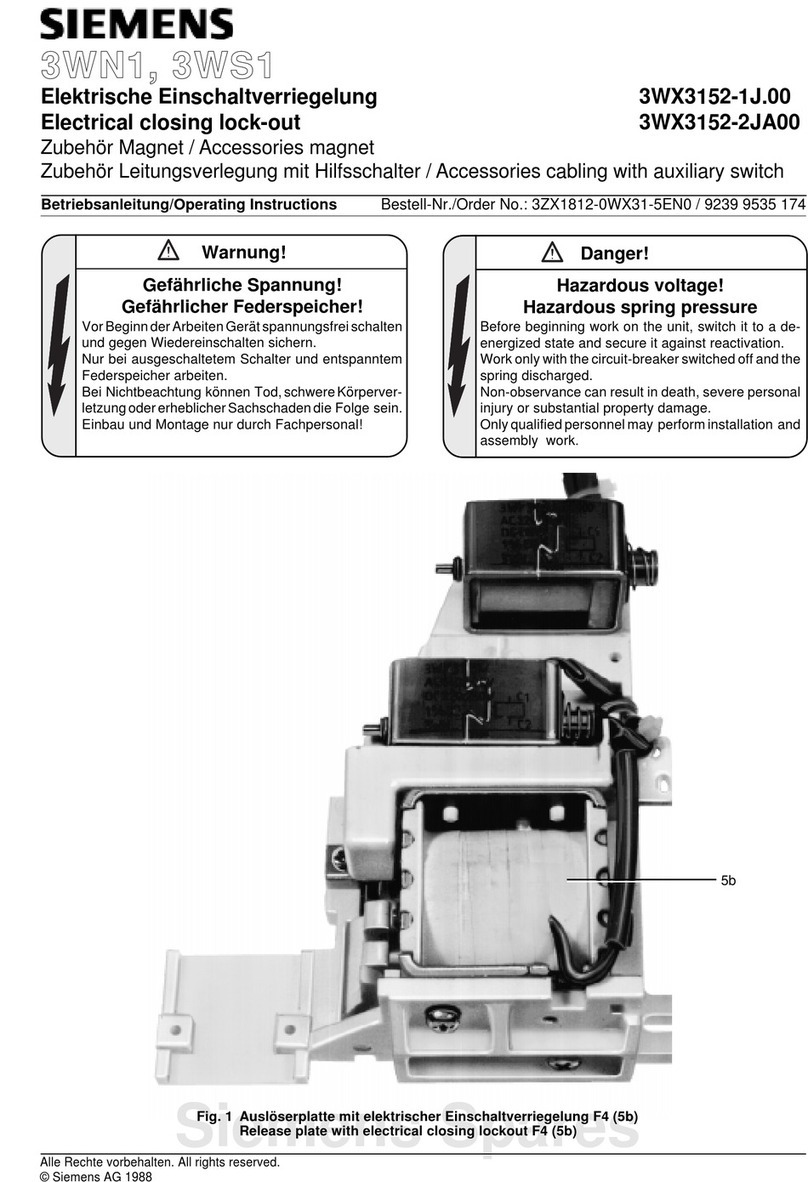

(Refer to Figure 6)

15. Slide the breaker “ON”-side stabs under the bus

straps, aligning the holes, and loosely fasten with the

M10 SEMS Screws (Item 21).

16. Loosely secure the breaker “OFF”-side to the Barrier

(Item 2) using the pair of M6 x 80mm mounting

screws that came with the breaker.

( Breaker sold separately)

17. Tighten all the screws

to the following torque:

M10 screws: 275 lb-in M6 screws: 18 lb-in

19. Re-install the “OFF”-side and modified “ON”-side

shield covers by sliding them down over the proper

ends, inserting the shield cover screws and tightening

to 13 lb-in.

18. Insert and secure the cables to the lugs on the

“OFF”-side of the breaker, and tighten to the torque

noted in the lug instruction sheet, on the device or

specified on the rear of the deadfront.

INSTALLING THE COVER PLATE:

21. Install the Cover Plate (Item 6) by aligning the opening

over the breaker and loosely secure it to the deadfront

support rails with the four 1/4”-20 x 3/8” screws (Item 18).

(Refer to Figure 8)

22. Once all the covers are in place, tighten all the screws

to the torque specified on the rear of the deadfront or

noted in the table on page 2.

23. Follow the

instructions

provided with the

Handle Extension

Holder Assembly

(Item 9) to locate

and install it.

Z-RAIL

AØ BØ CØ

19

1

Figure 3

8.75”

UNIT

SPACE

1.87”

AØ BØ CØ

Figure 4 20

2

20. If this kit is installed in a panelboard, install the

Panelboard Neutral Lug Assembly (Item 10).

If this kit is installed in a switchboard,

install the

Switchboard Neutral Lug Assembly (Item 11).

INSTALLING THE NEUTRAL LUG:

24. Ensure that any bus or breaker hardware is

torqued as specified on the rear of the deadfront.

Then replace all the cover plates and gutter

covers. Finally, ensure any fillers are in place

BEFORE re-energizing the equipment.

COMPLETING THE INSTALLATION:

HANDLE EXTENSION:

AØ

BØ CØ

Figure 6

21

“ON”

side

“OFF”

side

“ON”-side

Shield Cover

M6 x 80mm

Nut

Keeper

“OFF”-side

Shield Cover

Mesh

Shield

Screws

Figure 7b

11

Figure 7a 10

(Refer to Figures 7a and 7b)

18

Figure 8

6

HANDLE

EXTENSION

HANDLE

HOLDER

3VA BREAKER

ON / OFF

HANDLE

9

Figure 9

(Refer to Figure 9)

AØ

BØ

CØ

Figure 5

17

3

4

5

THIS KIT CONTAINS THE FOLLOWING ITEMS:

* This sub-kit of parts is packaged in a bag labeled “Standard Bus Hardware

Kit”. It includes an instruction card and 18 fasteners (of three different

lengths). Select fasteners per the instruction card and discard the rest.

ITEM

DESCRIPTION

QTY

1

2

3

4

5

6

7

8

9

10

Card Holder

#10-32 Thread-forming Screw

Handle Extension Holder Assembly

Medium Strap

Short Strap

Barrier

Circuit ID Card 1

1

1

1

1

1

1

1

11

12

Long Strap

Provision Filler

2

1

13

14

Panelboard Neutral Branch Lug Assy. 4

15

16 #10 Locknut

#10-24 x 5/8” Round-head Screw

1

2

Provision Strap Barrier

Switchboard Neutral Branch Lug Assy. 4

Mounting Bracket 2

Cover Plate 1

TORQUE

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

20 lb-in

30 lb-in

N/A

N/A

N/A

1/4”-20 x 1/2” Hex Head Washer Screw

1

4

17

1/4”-20 x 3/8” Hex Head Washer Screw

4

18

19

20

21 M10 SEMS Screw **

1/4”-20 x 1/2” Tall Hex Washer Screw

4

6

Bus Hardware Kit, Strap to Section * 72 lb-in

40 lb-in

72 lb-in

72 lb-in

275 lb-in

** Breakers ship with six M10 Screws; those should be discarded.

Instead, use the six M10 SEMS Screws included with this kit.

Hazardous voltage.

Will cause death or

serious injury.

Keep out.

Qualified personnel only.

Disconnect and lock off all

power before working on

this equipment.

DANGER

!