Installation Instructions

The following instructions are for the installation of Siemens Type GB2 breakers (NGB2, HGB2 or LGB2) as

branch devices in a Switchboard or Type P4 or Type P5 Panelboard. The parts provided in this kit connect

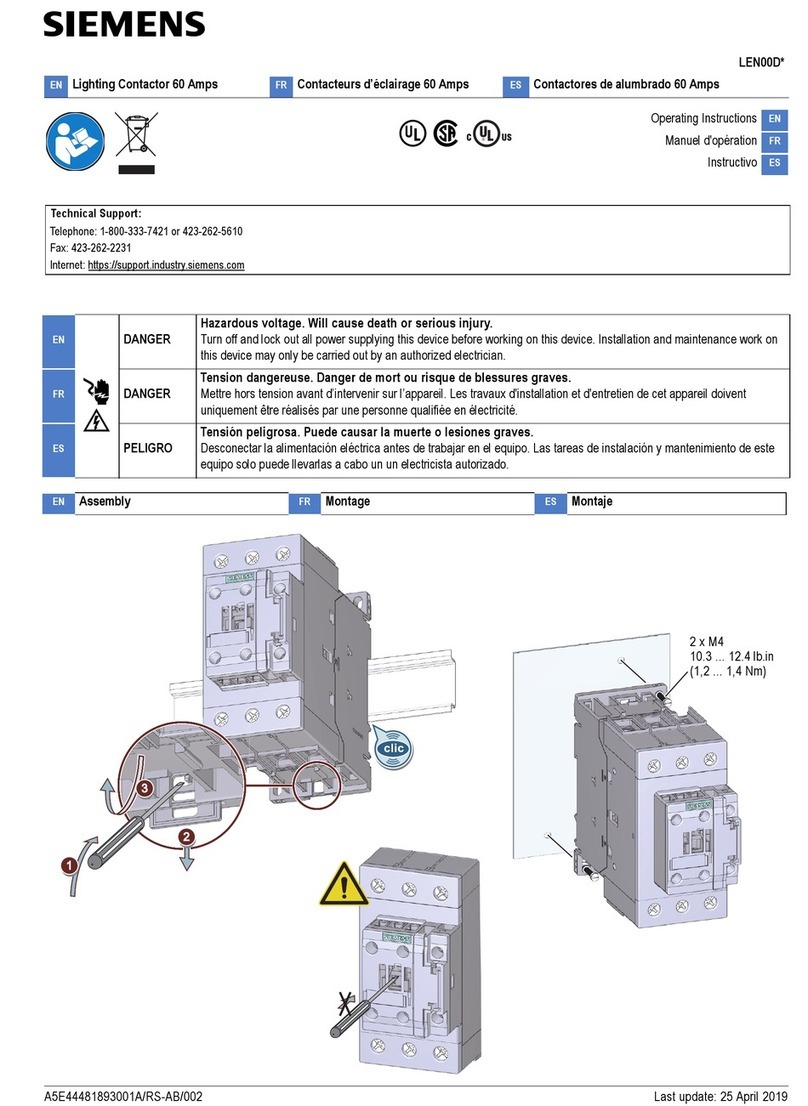

Type GB2 breakers to 3-phase/3-wire or 3-phase/4-wire systems ONLY. Kit SGB2 is for shallow (P4)

installations; kit SGB2D is for deep (P5 and Switchboard Distribution Section) installations. This kit requires

3-3/4” of unit space. NOTE: The breakers are NOT included in this kit and must be purchased separately.

12-A-1031-01 Rev. 00

-3--2-

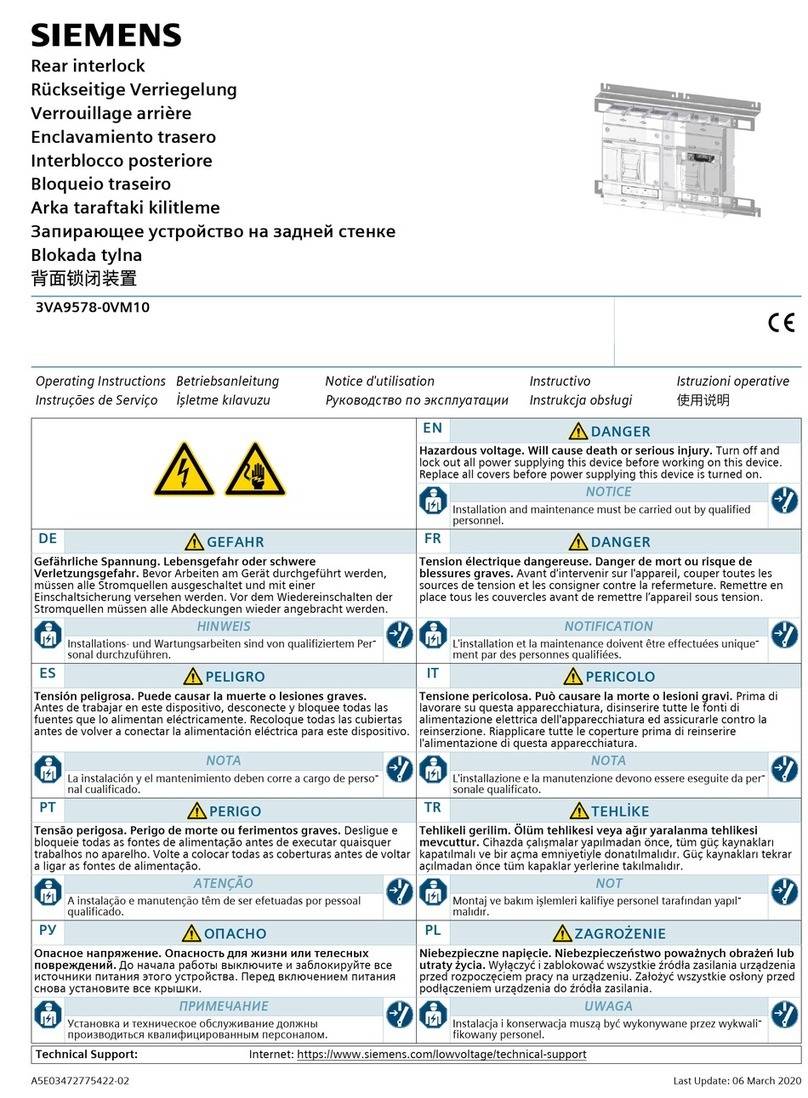

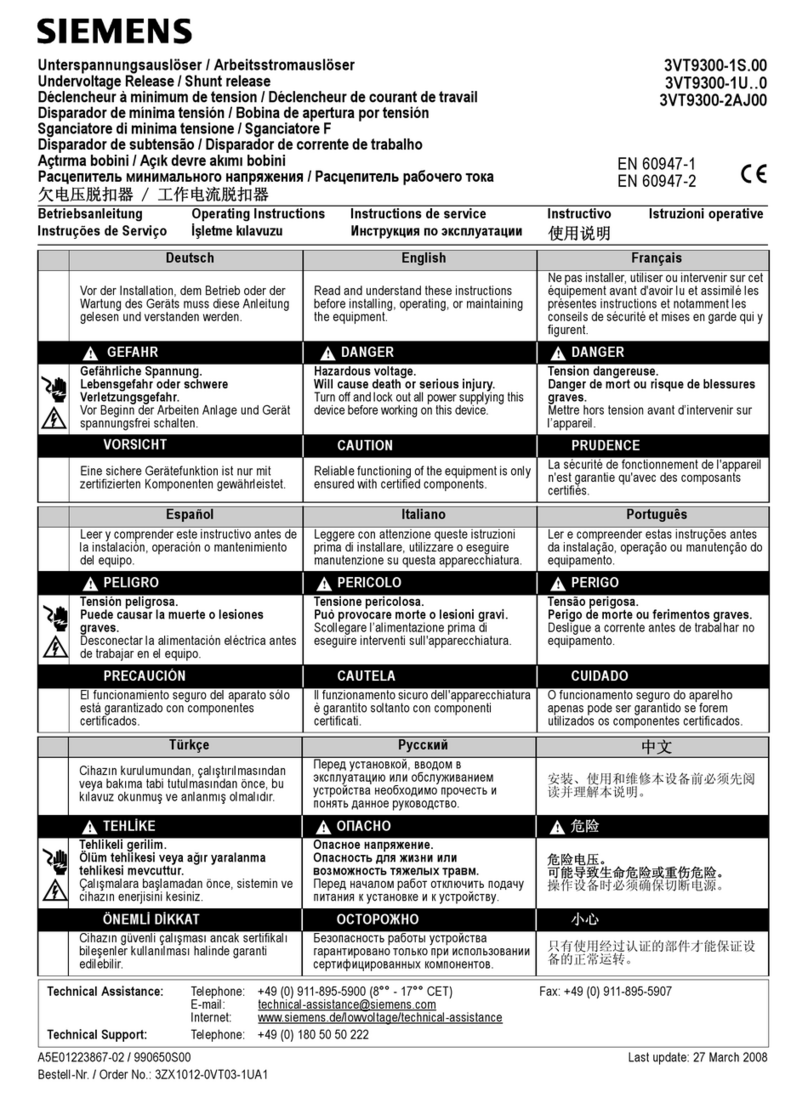

DANGER

Hazardous voltage.

Will cause death or

serious injury.

Keep out.

Qualified personnel only.

Disconnect and lock off all

power before working on

this equipment.

1. Lock off power supplying this equipment

before working on it.

7.

Reference Figure 4

Locate a 0.228” diameter hole in the left Z-rail

1.88” below the top of the empty unit space

selected. Insert a 1/4”-20 x 3/8” screw (Item 14)

through the barrier support bracket (Item 5)

mounting hole and into the selected hole in the

Z-rail (orienting the bracket as shown). Repeat

this for the second mounting bracket. Tighten

these two screws (Item 14).

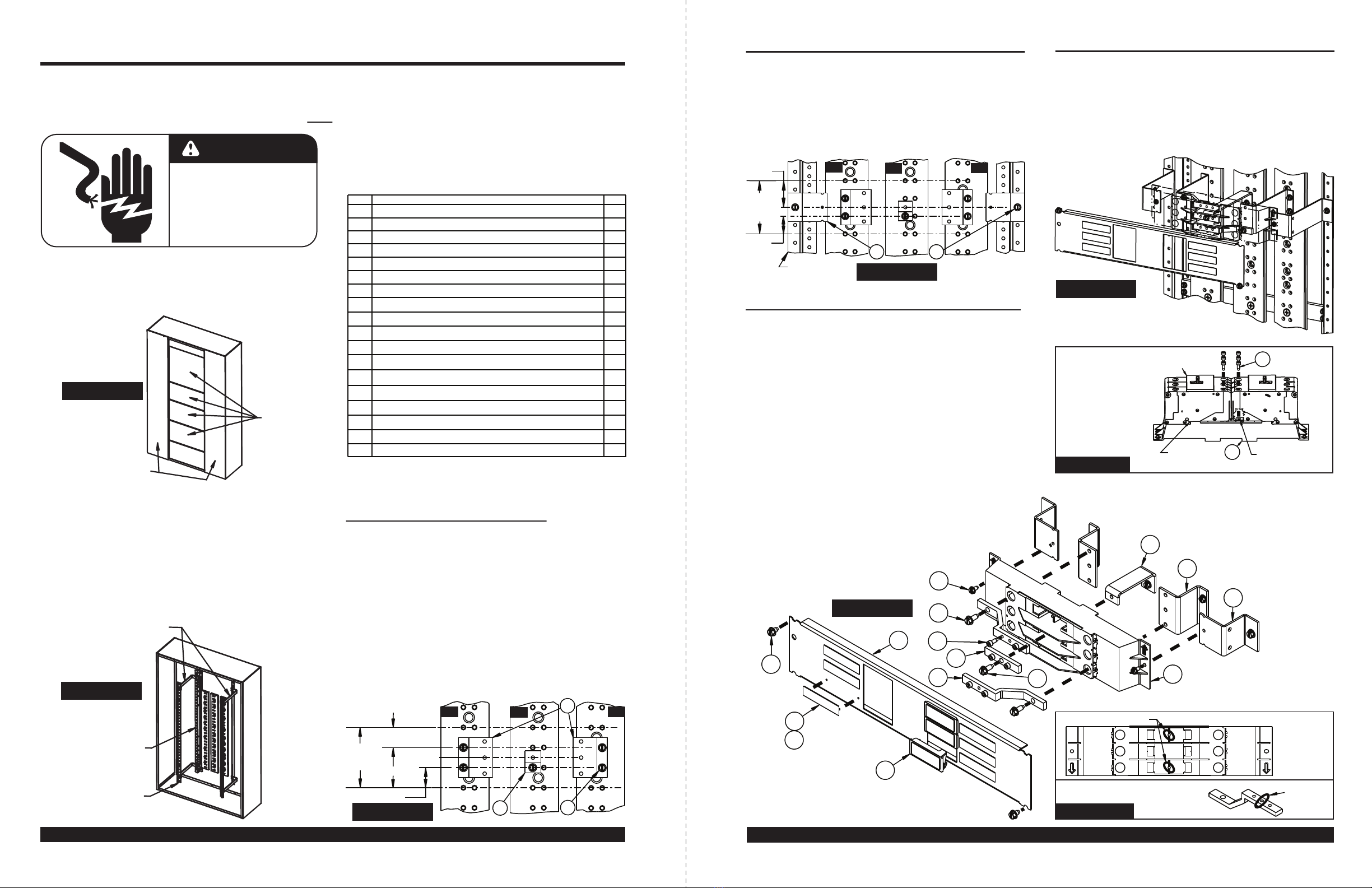

3. Refer to Figure 2

To mount a Siemens Type GB2 circuit breaker,

3-3/4” of empty unit space is required. To locate

the proper mounting position, measure from the

top deadfront support to the intended location of

the empty unit space (filler) on the deadfront.

Transfer this dimension from the deadfront

support along the Z-rail and mark. This will be

the unit space (as shown in Figures 3 & 4). After

marking the Z-rail, remove the deadfront rails.

4

.

If an existing branch module occupies the same

location chosen for this kit, remove all of its

devices, components and parts.

INSTALLING THE RUNBACKS

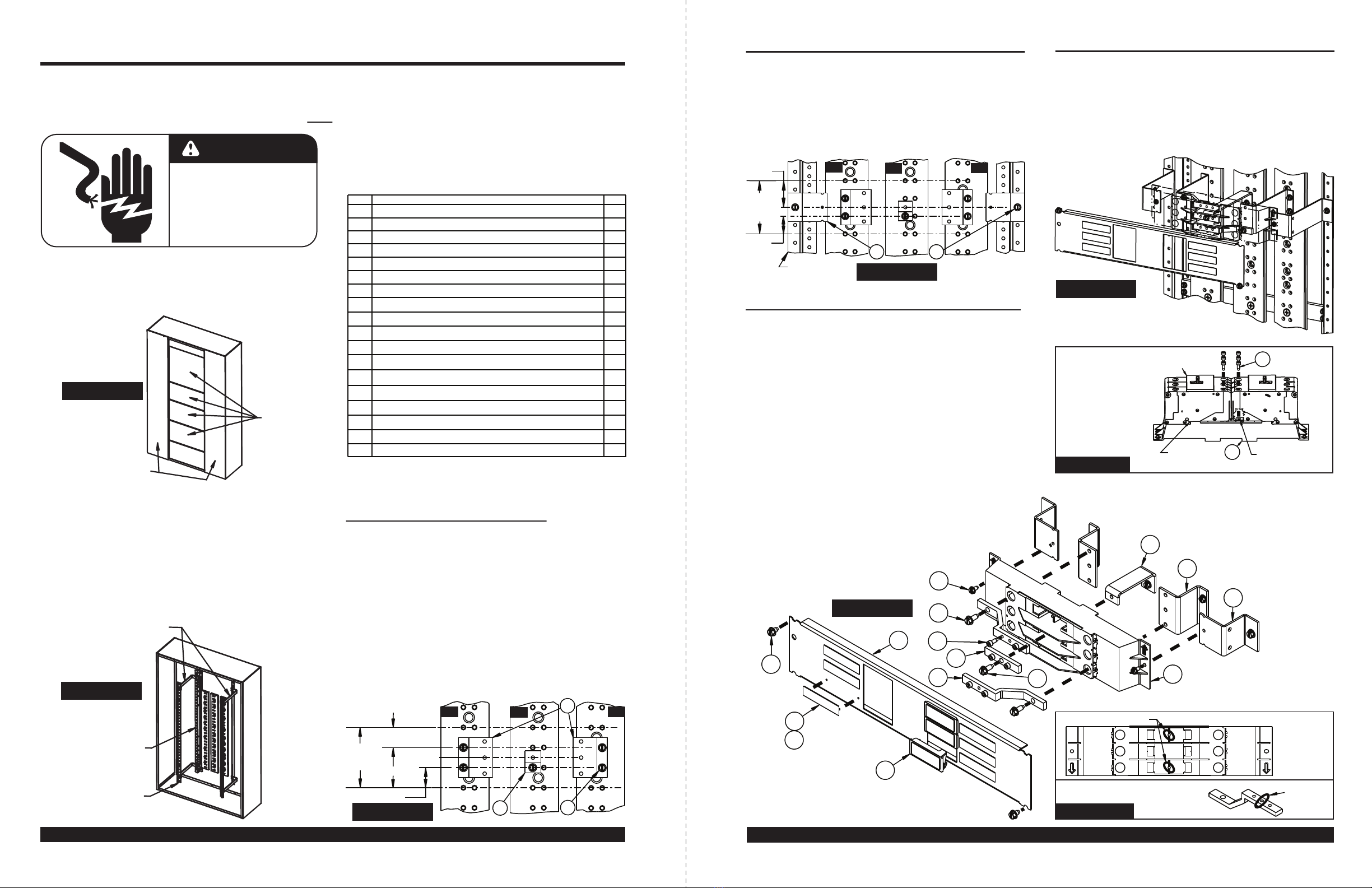

6. Refer to Figure 3

Locate (2) 0.228” diameter holes in the A-phase

bus 1.25” down from the top of the 3.75” empty

unit space selected. Insert (2) 1/4”-20 screws (see

mounting hardware kit instructions located in Item

11

for the proper length) through the two mounting

holes in the A/C runback (Item 1) and into the (2)

selected holes in the A-phase bus (orienting the

A/C strap as shown) and tighten. Repeat this step

to mount the second runback to the C-phase bus.

Insert one 1/4”-20 screw (Item 11) through the

mounting hole in the B-phase runback (Item 3) and

into the proper 0.228” hole located in the B-phase

bus, 1.25” up from the bottom of the 3.75” empty

unit space (orienting the B-phase runback as shown)

and tighten. Torque all hardware as specified on

the rear of the deadfront.

INSTALLING THE MOUNTING BRACKETS

9. Reference Figure 6

Align the bottom of the Type GB2 Breaker with the

top of the barrier. Slide the breaker along until the

notch on the bottom of the breaker fully engages

the edge of the barrier (as shown in Figure 6a).

Once fully engaged, use #10-24 x 1/2” screws

(Item 13) to secure the breaker tabs to the properly

aligned straps. Torque all hardware as specified

on the rear of the deadfront.

INSTALLING THE TYPE GB2 BREAKER

8. Reference Figure 5

Set the top barrier (Item 6) over the two barrier

support brackets (Item 5) such that the barrier

mounting holes align with the holes on the brackets.

Insert a #10-24 x 3/8” screw (Item 12) on each

side of the barrier and tighten. To install the

B-phase strap (Item 4), locate it in the center

opening such that the center hole lines up with

the mounting hole on the B-phase runback. Drive

a 1/4“-20 x 5/8” screw (Item 15) thru the strap and

into the runback and tighten. For the A & C-phase

straps (Item 2) take one and angle the mounting

side under the barrier such that the strap

mounting hole aligns with the appropriate hole in

the A-phase runback and the center hole of the

strap sits on the barrier locating pin (Figure 5a).

Drive a 1/4”-20 x 5/8” screw (Item 15) through the

strap and into the runback and tighten. Repeat

this for the C-phase strap as shown. Torque all

hardware as specified on the rear of the deadfront.

INSTALLING THE BARRIER & STRAPS

Figure 1

Figure 4

CENTER

HOLE

LOCATING PINS

Figure 5a

GB2

TOP

BARRIER

A/C

PHASE

STRAP

2. Refer to Figure 1

Remove the gutter covers and cover plates.

Figure 2

5. Open the shipping box and inspect the contents.

Figure 3

Figure 5

Figure 6a

GB2

BREAKER

NOTCH

ENGAGEMENT

6GB2

BREAKER

LINE STAB

GB2

BREAKER

BASE NOTCH

13

GB2

BREAKER

COVER

PLATES

GUTTER

COVERS

(INLINE)

3.75”

UNIT

SPACE

2.50”

1.25”

1.25”

AØ BØ CØ

1

311

Z-RAIL

3.75”

UNIT

SPACE

AØ

1.88”

1.25”

BØ CØ

5

14

(SHALLOW KIT

REFERENCE)

3

1

5

6

2

4

13

15

12

8

9

10

14

7

Figure 6

(DEEP KIT

REFERENCE)

WARNING: Do NOT use with NGB, LGB or HGB breakers. ONLY use with NGB2, LGB2 or HGB2 breakers.

WARNING: Do NOT use with NGB, LGB or HGB breakers. ONLY use with NGB2, LGB2 or HGB2 breakers.

THIS KIT CONTAINS THE FOLLOWING ITEMS:

*

Kit contains shorter units for shallow applications (SGB2)

or taller units for deeper applications (SGB2D).

**

Application dictates amount of these components used.

*** SGB2D only

ITEM

DESCRIPTION

QTY

1

2

3

4

5

6

7

8

9

10

Circuit ID Card

#10-24 x 1/2” Socket Head Cap Screw

Card Holder

B-phase Strap

B-phase Runback *

A/C-phase Strap

3-3/4” Cover Plate 1

2

1

1

6

2

6

6

11

12

GB2 Barrier Support Bracket *

1/4”-20 x 5/8” Hex Head Washer Screw ** 5

2

13

14

Blank Filler ** 6

15

16 #8-32 x 5/8” Hex Head Washer Screw

1/4”-20 x 3/8” Hex Head Washer Screw 4

2

#10-24 x 3/8” Hex Head Washer Screw

Bus Hardware Kit, 1/8” Strap to Section ** 1

A/C-phase Runback * 2

GB2 Top Barrier 1

Branch Neutral Connector *** 1

17

18 Branch Neutral Terminal Strip 1

15

Z-RAIL

DEADFRONT

SUPPORTS

DEADFRONT

RAIL