Siko AG24 User manual

225/18

AG24

Actuator with interface

User manual

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 2 of 130

Table of contents

1General Information .................................................................................................. 8

1.1 Documentation ........................................................................................................8

2Display and control keys ............................................................................................ 8

2.1 LCD display..............................................................................................................8

2.2 LED display..............................................................................................................9

2.2.1 Status LED 1.........................................................................................................9

2.2.2 Status LED 2.........................................................................................................9

2.2.3 Network status LED 4.............................................................................................9

2.2.4 Link/Activity LED 5, 6..........................................................................................10

2.2.5 Module status LED 7 ............................................................................................10

2.3 Control keys...........................................................................................................10

2.3.1 Key lock and enable time .....................................................................................10

2.3.2 Value input ........................................................................................................11

2.3.3 Value selection ...................................................................................................11

2.4 Menu control .........................................................................................................12

2.4.1 Menu selection ...................................................................................................12

2.4.2 Changeable parameters menu................................................................................13

2.4.2.1 PCM menu ......................................................................................................13

2.4.3 Readable parameters menu ...................................................................................13

2.4.4 Error memory menu .............................................................................................14

3Functional description ............................................................................................. 14

3.1 User units .............................................................................................................14

3.1.1 Example of spindle drive ......................................................................................15

3.1.2 Example of toothed rod/pinion, straight toothing, metric division .............................15

3.1.3 Example external gear..........................................................................................15

3.2 Protective functions................................................................................................16

3.2.1 Current limiting ..................................................................................................16

3.2.2 I2t monitoring....................................................................................................17

3.2.3 Temperature monitoring.......................................................................................17

3.2.4 Overvoltage protection with energetic recovery .......................................................17

3.2.5 Contouring error monitoring .................................................................................17

3.3 Warnings / Errors....................................................................................................18

3.3.1 Warnings ...........................................................................................................18

3.3.2 Errors ................................................................................................................18

3.3.2.1 Error codes .....................................................................................................18

3.4 Operating modes ....................................................................................................19

3.4.1 Positioning mode................................................................................................19

3.4.1.1 Limiting values ...............................................................................................20

3.4.1.2 Limit switch....................................................................................................21

3.4.1.2.1 Example of a configuration............................................................................21

3.4.1.2.2 Assembly of the limit switches.......................................................................22

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 3 of 130

3.4.1.3 Loop positioning .............................................................................................22

3.4.1.4 Inching operation............................................................................................23

3.4.1.4.1 Inching operation 1 .....................................................................................23

3.4.1.4.2 Inching operation 2 .....................................................................................24

3.4.1.5 Travel Against Load .........................................................................................24

3.4.1.6 Control word: Positioning mode (master slave)................................................25

3.4.1.7 Status word: Positioning mode (slave master) .................................................26

3.4.1.8 Flow chart: Operating mode Positioning mode .....................................................27

3.4.2 Local control (Stand-Alone Operation) ...................................................................28

3.4.2.1 Inching operation 2.........................................................................................28

3.4.2.2 Specifying the set point ...................................................................................28

3.4.3 Digital inputs and outputs....................................................................................29

3.4.3.1 Examples of digital input configurations.............................................................30

3.4.3.2 Example of digital output configuration..............................................................31

3.4.4 Position Control Mode..........................................................................................31

3.4.4.1 Examples of configuration of the digital inputs for the PCM...................................32

3.4.5 Calibration .........................................................................................................33

3.4.6 Sense of Rotation ...............................................................................................34

3.4.7 Rotational speed mode ........................................................................................34

3.4.7.1 Control word Operating mode: Speed mode..........................................................35

3.4.7.2 Status word Operating mode: Speed mode...........................................................36

3.4.7.3 Flow chart: Operating mode Speed mode.............................................................37

4EtherNet/IP™ .......................................................................................................... 38

4.1 Description............................................................................................................38

4.1.1 IP-Configuration .................................................................................................38

4.1.2 I/O Messages......................................................................................................40

4.1.3 Explicit Messages ................................................................................................40

4.1.4 ADI Object (Class A2h).........................................................................................40

4.2 CIP objects ............................................................................................................41

4.2.1 Identity Object (Class 01h)...................................................................................42

4.2.1.1 Class attributes of the Identity Object ................................................................42

4.2.1.2 Instance attributes of the Identity Object...........................................................42

4.2.1.3 Status............................................................................................................43

4.2.1.4 Reset service of the Identity Object ...................................................................44

4.3 Commissioning aids ................................................................................................44

5Parameters.............................................................................................................. 44

5.1 Positioning............................................................................................................45

5.1.1 Sense of Rotation ...............................................................................................45

5.1.2 Spindle Pitch......................................................................................................45

5.1.3 Gear Ratio Numerator ..........................................................................................46

5.1.4 Gear Ratio Denominator .......................................................................................47

5.1.5 Pos Window........................................................................................................47

5.1.6 Offset Value .......................................................................................................48

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 4 of 130

5.1.7 Delta Inch..........................................................................................................48

5.1.8 Inpos Mode........................................................................................................49

5.1.9 Pos Type............................................................................................................50

5.1.10 Loop Length.......................................................................................................50

5.1.11 Calibration Value.................................................................................................51

5.1.12 Control Word ......................................................................................................51

5.1.13 Status Word .......................................................................................................52

5.1.14 Target Value.......................................................................................................53

5.1.15 Actual Value.......................................................................................................53

5.1.16 System Status Word.............................................................................................54

5.2 Actuator................................................................................................................56

5.2.1 Operating Mode ..................................................................................................56

5.2.2 A-Pos ................................................................................................................57

5.2.3 V-Pos ................................................................................................................57

5.2.4 D-Pos ................................................................................................................58

5.2.5 A-Inch...............................................................................................................59

5.2.6 V-Inch...............................................................................................................59

5.2.7 Inching 2 Offset .................................................................................................60

5.2.8 A-Rot ................................................................................................................60

5.3 Limiting values ......................................................................................................61

5.3.1 Software Limit 1 .................................................................................................61

5.3.2 Software Limit 2 .................................................................................................62

5.3.3 Peak Current Limit...............................................................................................62

5.3.4 Peak Current Time ...............................................................................................63

5.3.5 Continuous Current..............................................................................................63

5.3.6 Contouring Error Limit .........................................................................................64

5.3.7 Travel Against Load Trigger ..................................................................................64

5.3.8 Travel Against Load Direction ...............................................................................65

5.4 Visualization..........................................................................................................66

5.4.1 Display Orientation .............................................................................................66

5.4.2 Display Divisor....................................................................................................66

5.4.3 Display Divisor Application...................................................................................67

5.4.4 Decimal Places....................................................................................................67

5.4.5 Direction Indication Function ...............................................................................68

5.4.6 Displayed Value 2nd Line .....................................................................................69

5.5 Options.................................................................................................................70

5.5.1 Key Enable Time..................................................................................................70

5.5.2 Key Function Enable ............................................................................................70

5.5.3 Inching 2 Acceleration Type .................................................................................71

5.5.4 Inching 2 Stop Mode ...........................................................................................72

5.5.5 PIN Change ........................................................................................................72

5.5.6 Generic Mapping Parameter ..................................................................................73

5.5.7 Configuration .....................................................................................................74

5.5.8 S-Command........................................................................................................75

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 5 of 130

5.6 Controller parameter ...............................................................................................76

5.6.1 Controller Parameter P .........................................................................................76

5.6.2 Controller Parameter I .........................................................................................76

5.6.3 Controller Parameter D.........................................................................................77

5.7 Digital input/output ...............................................................................................78

5.7.1 Digital Input 1 Functionality ................................................................................78

5.7.2 Digital Input 2 Functionality ................................................................................79

5.7.3 Digital Input 3 Functionality ................................................................................79

5.7.4 Digital Input 4 Functionality ................................................................................80

5.7.5 Digital Inputs Polarity .........................................................................................81

5.7.6 Digital Input Functionalities State.........................................................................82

5.7.7 Digital Inputs State.............................................................................................83

5.7.8 Digital Output 1 Functionality...............................................................................83

5.7.9 Digital Outputs Polarity........................................................................................84

5.7.10 Digital Output Functionalities State.......................................................................85

5.7.11 Digital Outputs Control ........................................................................................86

5.7.12 Service Interface Baud Rate..................................................................................86

5.8 Position Control Mode .............................................................................................87

5.8.1 PCM Position 1 ...................................................................................................87

5.8.2 PCM Position 2 ...................................................................................................88

5.8.3 PCM Position 3 ...................................................................................................88

5.8.4 PCM Position 4 ...................................................................................................89

5.8.5 PCM Position 5 ...................................................................................................89

5.8.6 PCM Position 6 ...................................................................................................90

5.8.7 PCM Position 7 ...................................................................................................91

5.8.8 PCM Acceleration 1..............................................................................................91

5.8.9 PCM Acceleration 2..............................................................................................92

5.8.10 PCM Acceleration 3..............................................................................................92

5.8.11 PCM Acceleration 4..............................................................................................93

5.8.12 PCM Acceleration 5..............................................................................................93

5.8.13 PCM Acceleration 6..............................................................................................94

5.8.14 PCM Acceleration 7..............................................................................................95

5.8.15 PCM Velocity 1....................................................................................................95

5.8.16 PCM Velocity 2....................................................................................................96

5.8.17 PCM Velocity 3....................................................................................................96

5.8.18 PCM Velocity 4....................................................................................................97

5.8.19 PCM Velocity 5....................................................................................................98

5.8.20 PCM Velocity 6....................................................................................................98

5.8.21 PCM Velocity 7....................................................................................................99

5.8.22 PCM Deceleration 1 .............................................................................................99

5.8.23 PCM Deceleration 2 ........................................................................................... 100

5.8.24 PCM Deceleration 3 ........................................................................................... 101

5.8.25 PCM Deceleration 4 ........................................................................................... 101

5.8.26 PCM Deceleration 5 ........................................................................................... 102

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 6 of 130

5.8.27 PCM Deceleration 6 ........................................................................................... 102

5.8.28 PCM Deceleration 7 ........................................................................................... 103

5.9 Device information ............................................................................................... 104

5.9.1 Output Stage Temperature .................................................................................. 104

5.9.2 Virtual Motor Temperature.................................................................................. 104

5.9.3 Voltage of Control............................................................................................. 105

5.9.4 Voltage of Output Stage..................................................................................... 105

5.9.5 Motor Current ................................................................................................... 106

5.9.6 Actual Position ................................................................................................. 107

5.9.7 Actual Rotational Speed..................................................................................... 107

5.9.8 Overload .......................................................................................................... 108

5.9.9 Actual Contouring Error...................................................................................... 108

5.9.10 Gear Reduction ................................................................................................. 109

5.9.11 Encoder Resolution............................................................................................ 109

5.9.12 Serial Number................................................................................................... 110

5.9.13 SW Motor Controller........................................................................................... 111

5.9.14 SW Ethernet Module .......................................................................................... 111

5.9.15 Production Date................................................................................................ 112

5.9.16 Device ID......................................................................................................... 112

5.9.17 Generic Mapping Channel ................................................................................... 113

5.10 Error memory ....................................................................................................... 114

5.10.1 Number of Errors............................................................................................... 114

5.10.2 Error Number 1 ................................................................................................. 114

5.10.3 Error Number 2 ................................................................................................. 115

5.10.4 Error Number 3 ................................................................................................. 115

5.10.5 Error Number 4 ................................................................................................. 116

5.10.6 Error Number 5 ................................................................................................. 117

5.10.7 Error Number 6 ................................................................................................. 117

5.10.8 Error Number 7 ................................................................................................. 118

5.10.9 Error Number 8 ................................................................................................. 118

5.10.10 Error Number 9 ................................................................................................. 119

5.10.11 Error Number 10................................................................................................ 119

6Service protocol......................................................................................................120

6.1 General Information.............................................................................................. 120

6.1.1 Communication................................................................................................. 120

6.1.2 Settings........................................................................................................... 120

6.1.3 ASCII commands............................................................................................... 120

6.1.4 Responses........................................................................................................ 121

6.2 Commands........................................................................................................... 121

6.2.1 Start travel job ................................................................................................. 121

6.2.2 Start of inching mode1 ...................................................................................... 121

6.2.3 Start inching mode 2 positive travel direction....................................................... 121

6.2.4 Start inching mode 2 negative travel direction ...................................................... 121

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 7 of 130

6.2.5 Cancel current travel job in positioning mode ....................................................... 121

6.2.6 Motor stop fast................................................................................................. 122

6.2.7 Motor stop ....................................................................................................... 122

6.2.8 Activate motor ................................................................................................. 122

6.2.9 Factory setting: all parameters............................................................................ 122

6.2.10 Factory setting: Standard parameter .................................................................... 122

6.2.11 Factory setting: Controller parameter ................................................................... 122

6.2.12 Factory setting: Visualization parameters.............................................................. 123

6.2.13 Factory setting: Network parameters .................................................................... 123

6.2.14 Acknowledge error............................................................................................. 123

6.2.15 Calibrate.......................................................................................................... 123

6.2.16 Delete error memory .......................................................................................... 123

6.2.17 Software reset .................................................................................................. 123

6.3 Flow charts.......................................................................................................... 124

6.3.1 Flow chart: Operating mode: Positioning mode...................................................... 124

6.3.2 Flow chart: Operating mode: Speed mode ............................................................. 125

6.4 Error number encoding .......................................................................................... 125

6.5 Examples............................................................................................................. 126

6.5.1 Write and read set point +500............................................................................. 126

6.5.2 Start travel job ................................................................................................. 126

6.6 ASCII command structure ...................................................................................... 126

6.7 Commissioning aids .............................................................................................. 127

7Ethernet Functions .................................................................................................128

7.1 Web server........................................................................................................... 128

7.2 FTP-Server ........................................................................................................... 129

7.3 Secure Host IP Configuration Protocol (Secure HICP) ................................................. 129

8Block diagram ........................................................................................................130

General Information

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 8 of 130

1General Information

1.1 Documentation

The following documents are associated with this document:

The data sheet describes the technical data, the dimensions, the pin assignment, the

accessories and the order key.

The installation instructions describe the mechanical and electrical installation with all

safety-relevant conditions and the associated technical specifications.

User manual describing the migration of the actuator into an Industrial Ethernet network

and its commissioning.

You can also download these documents at http://www.siko-global.com/p/ag24.

2Display and control keys

The actuator features a two-line display with special characters and three operating keys

, and .

The actuator can be configured and controlled via the keys.

The two LEDs and inform about the operating status of the actuator.

The four LEDs , , , and inform about the operating status of the Ethernet module.

Fig. 1: Display and control elements

2.1 LCD display

With operating voltage applied to the control unit, the actual value is displayed in the 1st line

and the target value is displayed in the 2nd line (factory setting). The value displayed in the

2nd line can be chosen by means of parameter setting (see chapter 5.4.6). In the positioning

mode, the direction indicators in the display indicate the key to be pressed for the inching

mode to get to the set positioning window (see chapter 5.4.5). For signaling the speed mode,

both direction indicators are activated in the display.

Display and control keys

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 9 of 130

2.2 LED display

2.2.1 Status LED 1

If the actual value is unequal after switching on the module and if it is

outside the programmed positioning window, then the LED status is "red" or

"red, flashing" due to volatile storage of the set point. The set point is

initialized with the value 0 after switching on.

LED state

Description

green

Actuator is within the programmed positioning window.

Operating voltage of the output stage is applied.

green, flashing

Actuator is within the programmed position window.

Operating voltage of the output stage missing.

red

Actuator is outside the programmed positioning window.

Operating voltage of the output stage is applied.

red, flashing

Actuator is outside the programmed positioning window.

Operating voltage of the output stage missing.

off

Operating voltage of control missing.

2.2.2 Status LED 2

LED state

Description

green

Operating voltage applied to control, no fault.

red, flashing

Operating voltage applied to control, active fault.

flashing

red/green

Operating voltage of control is applied, switch lock active.

off

Operating voltage of control missing.

2.2.3 Network status LED 4

A test sequence is executed on this LED after switching on the device.

LED state

Description

off

No operating voltage or no IP address.

green

On-line, one or multiple connections established (CIP Class 1 or 3).

green, flashing

On-line, no connection established.

red

Double IP address, fatal error.

red, flashing

On-line, one or multiple connections timeout (CIP Class 1 or 3).

Display and control keys

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 10 of 130

2.2.4 Link/Activity LED 5, 6

LED state

Description

off

no connection, no activity

green

connection (100 Mbit/s) established

green, flickers

activity (100 Mbit/s)

yellow

connection (10 Mbit/s) established

yellow, flickers

activity (10 Mbit/s)

2.2.5 Module status LED 7

A test sequence is executed on this LED after switching on the device.

LED state

Description

off

no operating voltage

green

control via scanner

green, flashing

not configured or scanner inactive

red

serious error

red, flashing

Correctable error. The module has been configured but the stored

parameters differ from the parameters presently used.

2.3 Control keys

After applying operating voltage to the control, the actuator will be on the highest level of

the menu structure, the positioning mode will be active (factory setting).

Pressing the - key starts leftward travel (inching operation 2).

Pressing the - key starts rightward travel (inching operation 2).

Releasing the respective key stops travel movement.

Pressing the - key starts the parameter / programming mode.

2.3.1 Key lock and enable time

The access via keys to the functions of Inching mode 2, positioning mode and speed mode

can be generally locked via the Key Function Enable parameter (see chapter 5.5.2). Temporary

locking or enabling is possible via the control word Bit 9. The Key Enable Time parameter

(see chapter 5.5.1) defines the necessary period of holding down the asterisk key until you

get to the menu or until the set point setting via the display is enabled, respectively.

Display and control keys

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 11 of 130

2.3.2 Value input

When you enter values via the keys, the display range is limited to -199999

… 999999. If values beyond this range are entered via the network or

service protocol, "FULL" will be displayed when the parameter is called up.

Enter values via the key and the key.

Confirm values entered by pressing the key.

key: decimal place selection

key: value input

2.3.3 Value selection

For some parameters you can select values from a list. Direct value input is not possible there.

Pressing the key, the value can be selected from the list. By pressing the key, the

selection is confirmed.

Display and control keys

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 12 of 130

2.4 Menu control

2.4.1 Menu selection

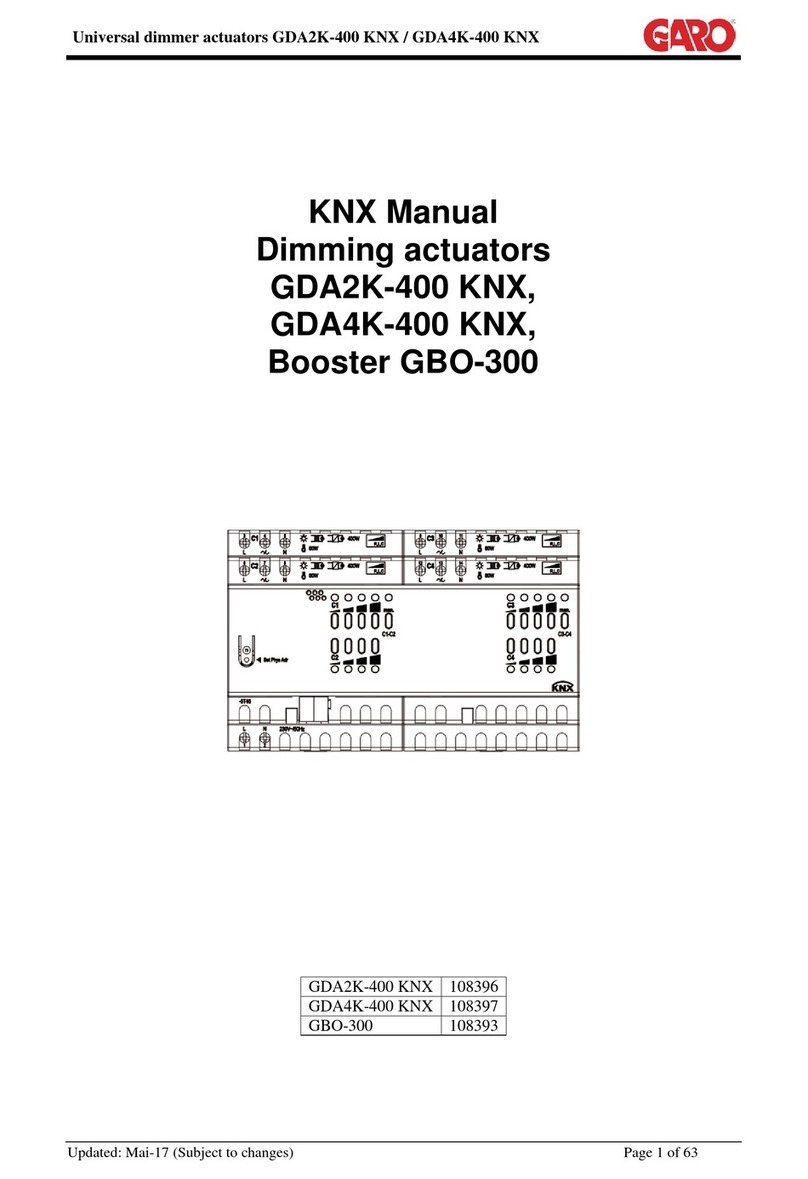

Start

Hold down

key

Key enable time

exprired?

Changeable parameters

PARAM

CHANGE

Read-only parameters

PARAM

RoPARA

Error memory

PARAM

ErrBuF

Changeable

parameters

menu

PIN entry required

Readable

parameters

menu

Error memory

menu

End

yes

no

PIN correct? yes

no

Fig. 2: Menu selection

Display and control keys

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 13 of 130

2.4.2 Changeable parameters menu

The changeable parameters menu is structured as follows:

Description

Display

Page

EtherNet/IP

EIP

38

Positioning

POSIT

45

Actuator

DRIVE

56

Limiting values

BOUNDS

61

Visualization

VISUAL

66

Options

OPTION

70

Controller parameter

CONTR

76

Digital input/output

DIG IO

77

Position Control Mode

PCM

87

2.4.2.1 PCM menu

The PCM menu is divided into single sets of parameters. A set of parameters contains a travel

dataset, e. g. PARAM CHANGE \ PCM \ PCM SET 1 \.

Description

Display

PCM Position 1

POS 1

PCM Acceleration 1

ACC 1

PCM Velocity 1

VEL 1

PCM Deceleration 1

DEC 1

2.4.3 Readable parameters menu

The readable parameters menu contains device information.

Description

Display

Chapter

Output Stage Temperature

OS DEG

5.9.1

Virtual Motor Temperature

VM DEG

5.9.2

Voltage of Control

C VOLT

5.9.3

Voltage of Output Stage

P VOLT

5.9.4

Motor Current

MotCur

5.9.5

Actual Position

POS

5.9.6

Actual Rotational Speed

VEL

5.9.7

Overload

OVLOAD

5.9.8

Gear Reduction

REduc

5.9.10

Encoder Resolution

EncRES

5.9.11

Digital Inputs State

DI4321

5.7.7

Digital Output State

DO 1

SW Motor Controller

VErDrv

5.9.13

SW Ethernet Module

VErMod

5.9.14

Functional description

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 14 of 130

Description

Display

Chapter

Serial Number

SEr No

5.9.12

Production Date

DtProd

5.9.15

IP Address

IP 1.2 / 3.4

4.1.1

Subnet Mask

SNM 1.2 / 3.4

4.1.1

Gateway Address

GW 1.2 / 3.4

4.1.1

2.4.4 Error memory menu

The error memory menu contains the number and type of errors that occurred

(see chapter 3.3.2.1). Up to ten errors are stored non-volatilely in the error memory. Empty

memory locations are not listed in the menu. The last error is at the lowest position in the

menu.

Description

Display

Number of errors

Err No

Error number 1

Err 01

:

:

Error number 10

Err 10

Example: Err No = 6 > The last error is in the menu entry Err 06.

3Functional description

If there is no upstream control, you can control the drive via keys or digital inputs and service

interface, respectively. You can configure the drive via display and service interface.

3.1 User units

With factory settings, the drive works with 1024 steps per revolution.

If scaling is desired, with no need to consider the internal gearbox, the Spindle Pitch

(see chapter 5.1.2), Gear Ratio Numerator (see chapter 5.1.3) and Gear Ratio Denominator

(see chapter 5.1.4) parameters must be set correspondingly.

The scaled position value is calculated as follows:

The external gear ratio is calculated as follows (see chapter 3.1.3):

Value jumps will occur if scaling exceeds the absolute encoder's basic resolution of 1024 steps

per revolution.

The following condition shall be met for this reason:

Functional description

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 15 of 130

The travel range expressed as user units is calculated with the following formula:

3.1.1 Example of spindle drive

Spindle pitch p = 2 mm

The drive is mounted directly to a spindle.

The desired unit of the position value is 1/100 mm.

The Spindle Pitch parameter (see chapter 5.1.2) is calculated with the following formula:

3.1.2 Example of toothed rod/pinion, straight toothing, metric division

Division p = 5 mm

Number of pinion teeth z = 20

The desired unit of the position value is 1/10 mm.

The Spindle Pitch parameter (see chapter 5.1.2) is calculated with the following formula:

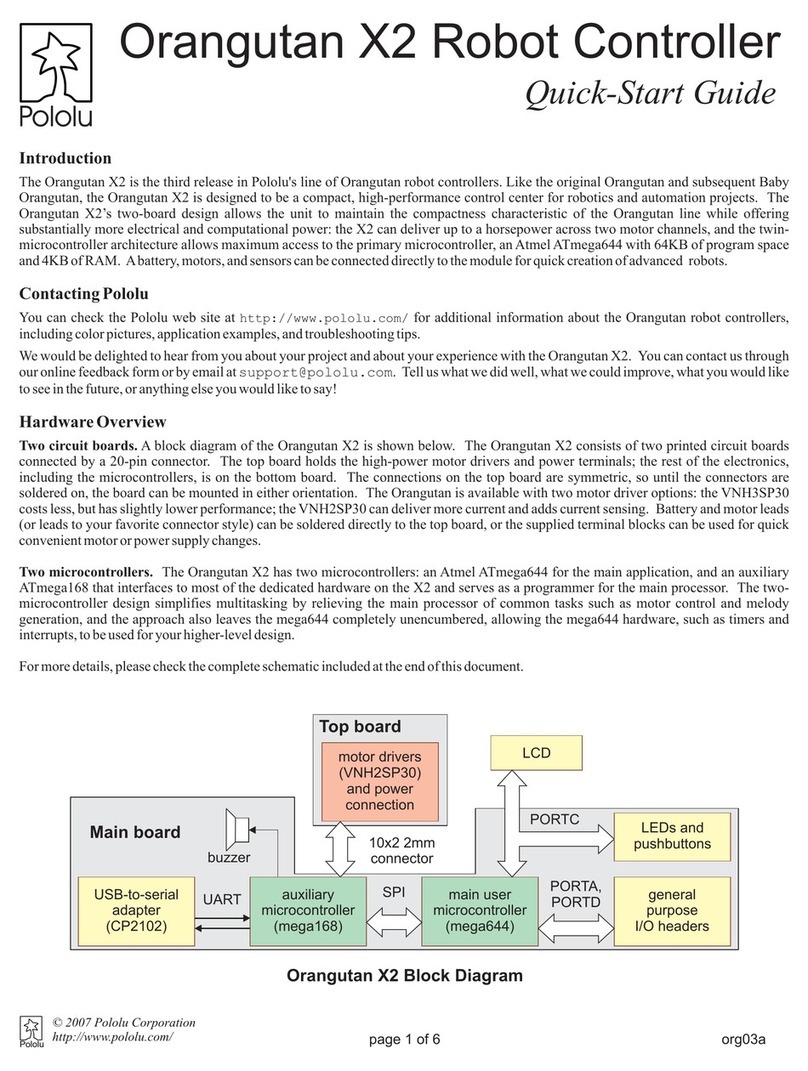

3.1.3 Example external gear

If an external gear is used, a factor can be programmed via the parameters Gear Ratio

Numerator (see chapter 5.1.3) and Gear Ratio Denominator (see chapter 5.1.4) in order to

include the gear ratio in position sensing.

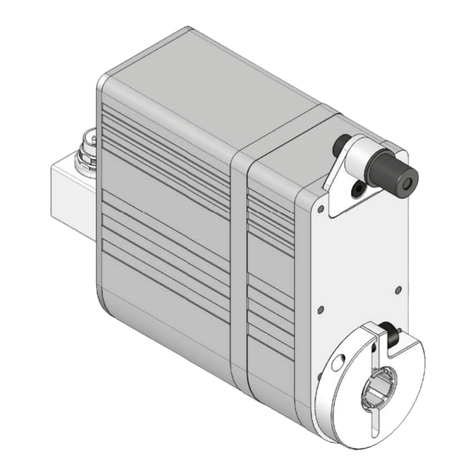

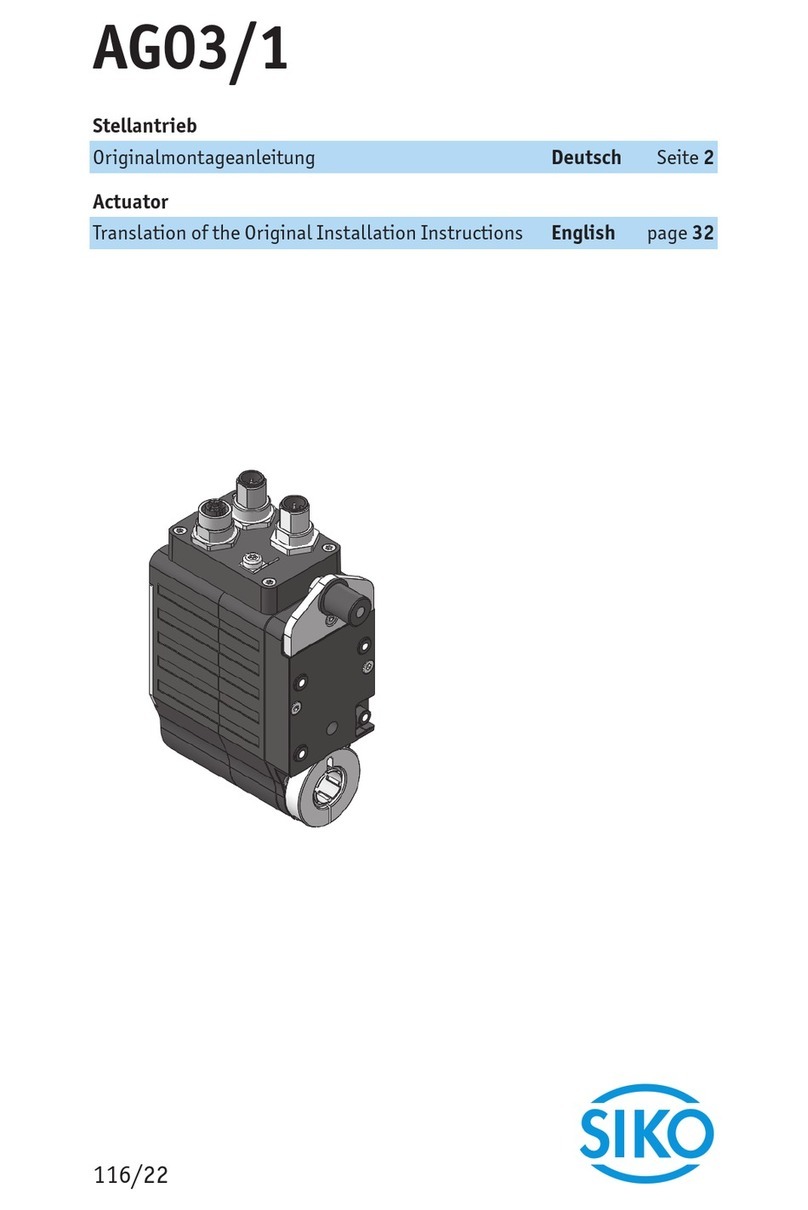

The actuator is operated on a gear (Fig. 3) with transmission reduction of 5:1. For this

purpose, the parameters must be programmed as follows:

Parameter Gear Ratio Numerator = 5

Parameter Gear Ratio Denominator = 1

Functional description

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 16 of 130

Fig. 3: External gear

Input of an odd gear transmission reduction value is possible according to the following

example:

Transmission reduction = 3.78

Parameter Gear Ratio Numerator = 378

Parameter Gear Ratio Denominator = 100

3.2 Protective functions

3.2.1 Current limiting

The actual motor current cannot be indicated by measuring the supply

current. With cycled output stages, the supply current does not correspond

to the motor current. Actual motor current can be read via the interface.

The current limit is set via parameter Peak Current Limit (see chapter 5.3.3), which serves

primarily for protecting the drive against overload.

With default set, nominal speed indicated on the data sheet is achieved.

Actuator overload results in limiting the motor current to the set value.

As a consequence, the actuator cannot maintain the speed set, the contouring error increases.

The actuator changes to the error status if the contouring error exceeds the contouring error

limit defined by the Contouring Error Limit parameter (see chapter 5.3.6): contouring error.

5 revolution

1 revolution

Gear output

external

gear unit

5:1

M

internal drive

Functional description

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 17 of 130

3.2.2 I2t monitoring

I2t monitoring serves the protection of the output stage and gear.

The I2t limit is calculated with the following formula:

The resulting peak current time is calculated with the following formula:

3.2.3 Temperature monitoring

The temperature of the output stage is measured directly on the output stage board. The

output stage is switched off at 90 °C.

The motor temperature is calculated from the motor current based on a thermal model. An

error is triggered when the motor temperature exceeds 105 °C.

3.2.4 Overvoltage protection with energetic recovery

Active overvoltage protection of the operating voltage of the output stage

is effective only with operating voltage of the control switched on.

The response of active overvoltage protection causes immediate

sluggishness of the driving shaft. This shall be considered when the driving

shaft is adjusted manually.

Besides overvoltage protection by means of passive overvoltage protection elements, the

actuator offers also active overvoltage protection of the operating voltage +UB output stage.

In case of voltage rise caused by energetic recovery (e. g., foreign adjustment), the motor

coils will be short-circuited for at least 4 s if the voltage of 32 V is exceeded. Excess energy

will be converted to heat in the motor coils.

3.2.5 Contouring error monitoring

Disturbance variables such as load and friction may lead to the actuator's inability to follow

the calculated travel profile. If the control deviation of the PID-positioning controller exceeds

the value defined by the Contouring Error Limit parameter (see chapter 5.3.6), the contouring

error will be triggered.

Functional description

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 18 of 130

3.3 Warnings / Errors

3.3.1 Warnings

Warnings do not influence the operation of the actuator.

Warnings disappear after removing the cause.

Possible warnings:

Current limiting active. The current limiting bit (bit 12) is set in the status word

(see chapter 3.4.1.7).

3.3.2 Errors

Errors cause an immediate stop of drive movement. For drives with the brake option, the brake

is activated. The drive will be activated if there is no brake option.

An error is indicated via the drive status LEDs and the display.

The error bit (Bit 7) is set in the status word

The error messages are entered in the error memory in the order of their detection. The last

10 error messages are displayed when the error memory is full.

The cause of error can be tracked down with the help of the error codes.

3.3.2.1 Error codes

If the error cannot be acknowledged after removal of the cause of error and

the error persists after power-on reset, then the drive must be inspected in

the factory.

Error code

Display

Fault

Trouble shooting

00h

-

No error

07h

C UVLT

Low control electronics voltage

check control operating voltage

08h

C OVLT

Control electronics overvoltage

check control operating voltage

09h

P OVLT

Power electronics overvoltage

check output stage operating

voltage

0Ah

TMP OS

Output stage excess temperature

reduce ambient temperature

reduce load

0Bh

LAG

Contouring error

reduce load

reduce acceleration or speed

0Ch

BLOCK

Output shaft blocked

disengage shaft

10h

Q1OVR

EEPROM queue overrun

internal error

13h

CSEEP

EEPROM check sum

reset parameters to factory

settings

14h

M WDER

Ethernet module watchdog

internal error

Functional description

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 19 of 130

Error code

Display

Fault

Trouble shooting

15h

M ERRO

Ethernet module in the ERROR

status while travel job is active

internal error

16h

M EXCE

Ethernet module in EXCEPTION state

internal error

The behavior of the drive when

this fault occurs can be set with

the parameter configuration, bit

6 (see chapter 5.5.7).

17h

ACYTO

Timeout in acyclic data exchange

check cycle time of the control

20h

I2T

I2T limit exceeded

reduce load

reduce acceleration or velocity

21h

TMO MO

Motor overtemperature

reduce load or duty cycle

22h

ENCODR

Encoder error

internal error

Table 1: Error codes

3.4 Operating modes

The following operating modes are distinguished: positioning mode and speed mode.

In the positioning mode, inching operation is additionally available. Drive control via digital

inputs and Position Control Mode is possible independent of the chosen operating mode.

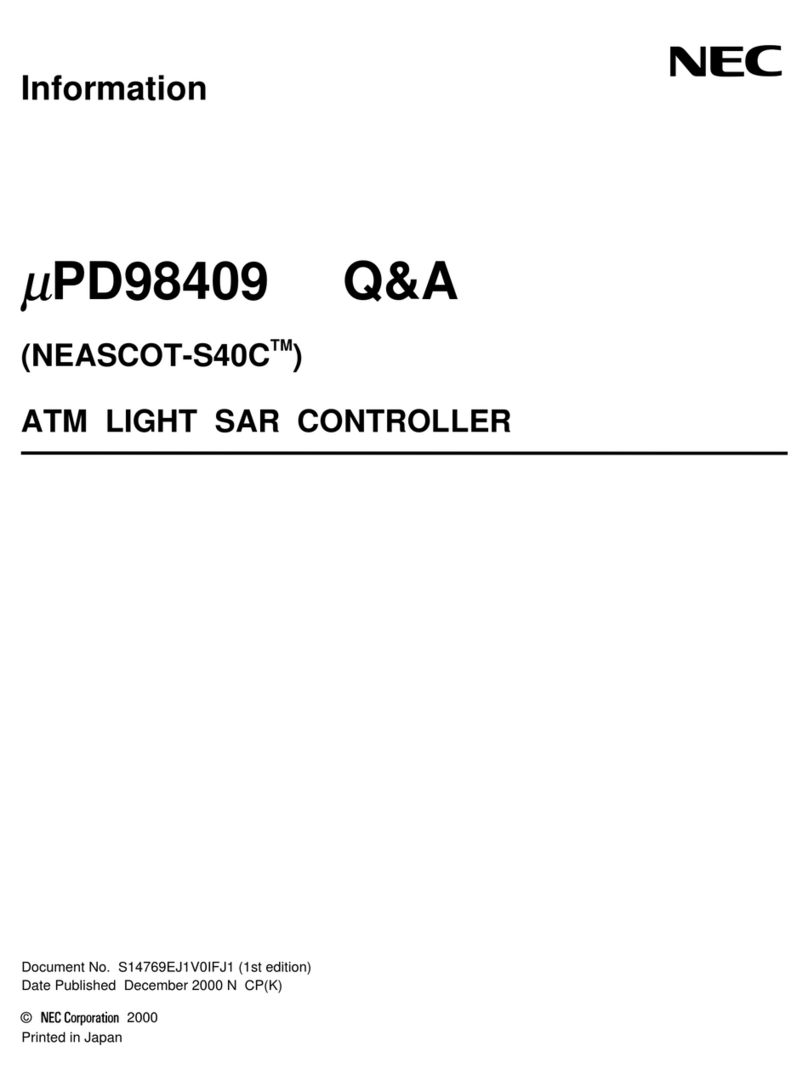

3.4.1 Positioning mode

In the positioning mode, positioning to the specified set point is executed by means of a

ramp function (Fig. 4) calculated on the basis of the actual position as well as the

programmed controller parameters acceleration and speed.

After activating the travel job, the actuator accelerates with the acceleration A-Pos

(see chapter 5.2.2) to velocity V-Pos (see chapter 5.2.3). The measure of delay until reaching

the set point is also A-Pos.

Alternately, the delay D-Pos (see chapter 5.2.4) can also be used to configure a value that

deviates from the acceleration.

The actuator is repositioned to the calculated path by means of PID position controller.

The controller can be optimized and adjusted to the local conditions via the Controller

Parameter P (see chapter 5.6.1), Controller Parameter I (see chapter 5.6.2) and Controller

Parameter D (see chapter 5.6.3) controller parameters.

Changing controller parameters during a positioning process does not influence the current

positioning operation.

Functional description

AG24 Date: 09.07.2018 Art. No. 89255 Mod. status 225/18 Page 20 of 130

Fig. 4: Ramp travel, direct positioning mode

If the actual position is inside the window defined by the Pos Window parameter

(see chapter 5.1.5), this will be signaled by Bit 5 = 1 in the status word. Upon reaching the

programmed window via parameter (see chapter 5.1.8), you can define the behavior of the

actuator.

Fig. 5: Positioning mode

3.4.1.1 Limiting values

Positioning operating mode:

If Software Limit 1 (see chapter 5.3.1) is equal Software Limit 2

(see chapter 5.3.2), then monitoring of the software limiting value is

deactivated. If the resolution of the absolute encoder is exceeded, there will

be a jump of the actual position.

Speed operating mode: insignificant

If the drive's position is outside the operating range defined by Software

Limit 1 and Software Limit 2, then traveling is only enabled in inching mode

in the direction of the operating range.

Start position

Target position

Time

Speed

V-Pos

A-Pos

D-Pos

A-Pos

Software Limit 1

Software Limit 2

Travel range

Upper limit

Travel range

Lower limit

+

-

0

Pos Window

Inpos Mode

-10

+10

Operating range

Other manuals for AG24

1

Table of contents

Other Siko Controllers manuals