Siko MSA501 User manual

330/18

MSA501

Actuator with CANopen interface

User manual

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 2 of 51

Table of contents

1General Information .................................................................................................. 4

1.1 Documentation ........................................................................................................4

1.2 Definitions ..............................................................................................................4

2Intended use............................................................................................................. 4

2.1 Switching on the supply voltage.................................................................................4

3Operating elements ................................................................................................... 5

3.1 General Information..................................................................................................5

3.2 LEDs .......................................................................................................................5

3.3 DIP switch (applies only to SP01 + SP03).....................................................................7

4Functional description ............................................................................................... 8

4.1 Measuring range.......................................................................................................8

4.2 Calibration ..............................................................................................................9

4.3 Reset to factory settings .........................................................................................10

5Communication via CAN bus (CANopen) .................................................................... 10

5.1 Telegram structure..................................................................................................10

5.2 Node control..........................................................................................................12

5.2.1 Network management (NMT) services .....................................................................12

5.2.1.1 NMT communication states ...............................................................................12

5.2.1.2 Toggling between the NMT communication states ................................................13

5.2.2 Boot-Up.............................................................................................................13

5.2.3 SYNC object........................................................................................................13

5.3 Process data exchange ............................................................................................14

5.3.1 Transfer of process data objects (PDO) ...................................................................14

5.3.1.1 Transmit PDO (from the MSA501 to the master) ...................................................14

5.3.1.2 Variable TPDO mapping.....................................................................................15

5.4 Parameter data exchange.........................................................................................16

5.4.1 Transmission of Service Data Objects (SDO).............................................................16

5.4.1.1 Expedited Request/Response .............................................................................16

5.4.1.2 Normal Request/Response.................................................................................18

5.4.1.3 Error Response in SDO exchange ........................................................................19

5.4.1.4 SDO examples .................................................................................................20

5.5 Node monitoring ....................................................................................................21

5.5.1 Emergency Service (EMCY) ....................................................................................21

5.5.2 Node Guarding....................................................................................................22

5.5.3 Heartbeat ..........................................................................................................23

5.6 Directory of objects ................................................................................................24

5.6.1 Overview of objects .............................................................................................24

5.6.2 Object description...............................................................................................25

5.6.2.1 1000h: Device Type..........................................................................................25

5.6.2.2 1001h: Error Register .......................................................................................26

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 3 of 51

5.6.2.3 1002h: Manufacturer Status Register ..................................................................26

5.6.2.4 1003h: Pre-defined Error Field...........................................................................27

5.6.2.5 1005h: COB-ID SYNC-Nachricht ..........................................................................27

5.6.2.6 1008h: Manufacturer Device Name .....................................................................28

5.6.2.7 1009h: Manufacturer Hardware Version ...............................................................28

5.6.2.8 100Ah: Manufacturer Software Version................................................................28

5.6.2.9 100Ch: Guard Time...........................................................................................29

5.6.2.10 100Dh: Life Time Factor....................................................................................29

5.6.2.11 1010h: Store Parameter....................................................................................29

5.6.2.12 1011h: Restore Parameter.................................................................................32

5.6.2.13 1014h: COB-ID Emergency-Nachricht ..................................................................34

5.6.2.14 1015h: Inhibit time EMCY .................................................................................34

5.6.2.15 1017h: Producer Heartbeat Time........................................................................35

5.6.2.16 1018h: Identity Objekt.....................................................................................35

5.6.2.17 1200h: Server SDO Parameter ............................................................................36

5.6.2.18 1800h: 1. Transmit PDO Parameter .....................................................................37

5.6.2.19 1801h: 2nd Transmit PDO Parameter...................................................................38

5.6.2.20 1A00h: 1. Transmit PDO Mapping Parameter ........................................................40

5.6.2.21 1A01h: 2. Transmit PDO Mapping Parameter ........................................................40

5.6.2.22 5115h: Calibrate encoder value..........................................................................41

5.6.2.23 5116h: Set the boundary ..................................................................................42

5.6.2.24 5122h: Register...............................................................................................42

5.6.2.25 5F09h: Bus terminator (not available with SP01 + SP03) .......................................44

5.6.2.26 5F0Ah: Node-ID and baud rate Bus CAN ..............................................................44

5.6.2.27 6000h: Operating Parameters ............................................................................45

5.6.2.28 6003h: Preset value (Calibration value) ..............................................................46

5.6.2.29 6004h: Position value ......................................................................................46

5.6.2.30 6005h: Resolution and velocity step width..........................................................46

5.6.2.31 6030h: Velocity value.......................................................................................47

5.6.2.32 6200h: Zyklus Timer.........................................................................................48

5.6.2.33 6500h: Operating Status...................................................................................48

5.6.2.34 6501h: Measuring step .....................................................................................48

5.6.2.35 6502h: Number of distinguishable revolutions .....................................................49

5.6.2.36 6507h: Profile and Software Version...................................................................49

5.6.2.37 6508h: Operating Time.....................................................................................49

5.6.2.38 6509h: Offset value .........................................................................................50

5.6.2.39 650Ah: Module Identification............................................................................50

5.6.2.40 650Bh: Serial number.......................................................................................51

General Information

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 4 of 51

1General Information

1.1 Documentation

The following documents are associated with this product:

Data sheet; it describes the technical data, the dimensions, the pin assignment, the

accessories and the order key.

Mounting instructions; they describe the mechanical and electrical installation with all

safety-relevant conditions and the associated technical specifications.

User manual; for commissioning the sensor and integrating it into a fieldbus system.

EDS file (electronic data sheet); this file enables integration and configuration in a

CANopen network by means of commercial CANopen configurators.

These documents can also be found at http://www.siko-global.com/p/msa501

1.2 Definitions

Decimal values are given as numbers without addition (e.g. 1234), except when indicated in

direct connection with binary or hexadecimal values in which case the extension d will be

used (e.g. 1234d). Binary values are identified by adding b (e.g. 1011b) to the figures

whereas hexadecimal values are extended by h (e.g. 280h).

2Intended use

The sensor collects the distance information of the coded MBA501 magnetic tape. By means

of the CANopen protocol, the sensor can be configured and read out via the CAN interface. For

instance, a superordinate control unit can read the absolute position value with a resolution

of 10 μm (or 5 μm, resp.).

On the upper side of the sensor there are 3 LEDs (yellow, red, green), which indicate error or

status information for diagnostic purposes.

If the sensor is lifted from the tape, an error will be detected and 0 will be output as the

position value and the yellow LED will flash 1x.

2.1 Switching on the supply voltage

MSA501 initializes after being switched on. During initialization, the LEDs light up one after

the other and the configuration parameters are loaded from the non-volatile memory to the

random memory of the controller.

Operating elements

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 5 of 51

The sensor will work with its default values as long as no changes have been made to it. With

parameters changed, the sensor will work with the changed data, which must be stored if they

are intended to be used after power off/on.

After completing the initialization procedure, the sensor sends a specific NMT command, the

boot-up message, which informs the system about the availability of the sensor. The MSA501

is now in the pre-operational mode. In this state, the sensor can be parameterized via SDO

commands in accordance with the requirements of the application. This applies to the

configuration parameters of the sensor unit as well as to the way it makes available to the

system its position values (asynchronous or synchronous data transmission).

3Operating elements

3.1 General Information

In its standard version, the sensor has a bus terminator, which can be energized via an SDO

object (see chapter 5.6.2.25 5F09h: Bus terminator (not available with SP01 + SP03)). The

SP01 +SP03 variant features an 8-pole DIP switch, which enables the adjustment of bus

terminator, node ID and baud rate. The sensor has 3 LEDs with yellow, green and red colors.

Fig. 1: Operating elements

3.2 LEDs

The device has 3 LEDs for diagnostic and status purposes,

A yellow LED for device-specific states

A green LED indicating the NMT status (CAN Run LED)

A red LED for CAN error states (CAN Err LED)

Operating elements

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 6 of 51

Device-specific diagnosis

The yellow LED is lit while the device is operating. It starts flashing when an error occurs. The

error states are differentiated by the number of LED flashes. The signal is repeated after a

pause of 600 ms. If multiple error states occur simultaneously, then the individual flash

signals add to form a sequence (e.g. yellow LED flashes 5x -> Sensor/tape reading distance

error state + velocity check).

Error state

Number of

flashes

Sensor/tape reading distance

1x

Plausibility of absolute value

2x

Velocity check (v > 5 m/s)

4x

Sensor-tape alignment

8x

Table 1: device-specific status LED

CAN diagnosis:

The CiA DS-303 Part 3 V1.4.0 indicator specification is the basis of the CAN diagnosis

LED state

Description

On

LED is permanently on

Off

LED is permanently off

Blinking

LED flashes at a frequency of 2.5 Hz (200 ms on/off)

Single Flash

LED is 200 ms on, 1000 ms off

Double Flash

LED is 200 ms on, 200 ms off, 200 ms on, 1000 ms off

Table 2: CAN LED statuses acc. to CiA DS-303

CAN Run LED:

NMT state

LED state

Pre-Operational

Flashing

Operational

On

Stopped

Single Flash

Table 3: CAN Run LED

CAN Err LED:

Error states

LED state

No error

Off

Warning limit reached (at least one error counter (Transmit Error

Counter CANTEC or Receive Error Counter CANREC) of the CAN

controller has reached or exceeded the warning limit (too many No

Error frames).

Single Flash

Error control event

=> A Guard Event (if no RTR Node guard received from master

within the lifetime set)

Double Flash

Operating elements

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 7 of 51

Error states

LED state

Bus off

On

Table 4: CAN Err LED

3.3 DIP switch (applies only to SP01 + SP03)

The device has an 8-pole DIP switch, which enables a bus resistor to be energized and the bus

node ID and baud rate to be configured. If the DIP switches are at the position “Use from

memory”, then the node ID and baud rate can be changed per CAN bus via object 5F0Ah:

Node-ID and baud rate Bus CAN. The switch position is scanned once during the startup

process. The adoption of a node ID or baud rate bus reset later occurs only after re-

initialization (see chapter 5.2.1 Network management (NMT) services).

Switch no.

1

2

3

4

5

6

7

8

Meaning

Bus baud rate

Node-ID (address)

Bus termination

Table 5: DIP switch

DIP switch

Bus baud rate

1

2

3

0

0

0

Use baud rate from memory

0

0

1

50k kBaud

0

1

0

100 kBaud

0

1

1

125 kBaud

1

0

0

250 kBaud

1

0

1

500 kBaud

1

1

0

1M Baud

1

1

1

Use baud rate from memory

Table 6: DIP switch for bus baud rate

DIP switches

Node-ID (Address)

4

5

6

7

0d

0d

0d

0d

Use address from memory

0d

0d

0d

1d

1d (1h)

0d

0d

1d

0d

2d (2h)

0d

0d

1d

1d

3d (3h)

0d

1d

0d

0d

4d (4h)

0d

1d

0d

1d

5d (5h)

0d

1d

1d

0d

6d (6h)

0d

1d

1d

1d

7d (7h)

1d

0d

0d

0d

8d (8h)

Functional description

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 8 of 51

DIP switches

Node-ID (Address)

4

5

6

7

1d

0d

0d

1d

9d (9h)

1d

0d

1d

0d

10d (Ah)

1d

0d

1d

1d

11d (Bh)

1d

1d

0d

0d

12d (Ch)

1d

1d

0d

1d

13d (Dh)

1d

1d

1d

0d

14d (Eh)

1d

1d

1d

1d

15d (Fh)

Tabelle 7: DIP switches Node-ID

4Functional description

4.1 Measuring range

The numbers given below refer to an absolute resolution of 0.005 mm; divide the numerical

values into half for an absolute resolution of 0.01 mm!

Representation of numerical values:

The numerical value output by the MSA501 sensor via the interface is always a multiple of the

resolution set.

Example:

Value output by the sensor = 340603; set resolution = 0.005 mm

-> position value = 340603 * 0,005 mm = 1703,015 mm

With a resolution set to 0.01 mm, the above output value corresponds to a position value of

3406,030 mm.

Tape coding:

The absolute coding of MBA501 enables a maximum measuring range of 10240 mm

(=2048000 * 0,005 mm).

Fig. 2: Tape coding

Position value:

In order to avoid jumps around the maximum value at position 0, this maximum value is

limited to 10000 mm (=2000000 * 0,005 mm). Thus, a range up to -240 mm (= -48000 *

0.005 mm) is possible in negative travel direction

0

+1

+2047999

+2047999

+1

0

Functional description

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 9 of 51

Fig. 3: Position value

Variable boundary:

In case the measurement range is to be extended in negative direction, there exists the

possibility of programming a positive value as a boundary via interface,

e.g.: Boundary = 6000 mm (measurement range = -4240 mm ... +6000 mm;

-4240 mm / 0.005 mm = 848000; +6000 mm / 0.005 mm = +1200000)

Fig. 4: Variable boundary:

Counting direction:

The sensor delivers ascending numerical values when the sensor is moved in the plug outlet

direction. This feature can be changed via object 6000h: Operating Parameters (descending

numerical values when the sensor is moved in the plug outlet direction).

4.2 Calibration

The MSA501 features an absolute measurement system, i.e. the information of the position

value is represented in the scale (MBA501 magnetic tape) as an absolute value. Calibration

can be performed at any position on the magnetic tape.

Position value = measured value + calibration value

The measured value is set to zero when calibrating.

At the actual sensor position, the value “position value = 0 + calibration value” is output from

then on. With calibration, the actual position value is replaced by the set calibration value

and stored non-volatilely.

Two steps are required for executing calibration:

1. Write calibration value (see Object 6003h: Preset value (Calibration value))

2. Execute calibration (reset) (see object 5115h: Calibrate encoder value)

The following equation is applied in case of calibration:

Position value = 0 + calibration value

-480000

0

+1

-1

-1

+1

0

-480000

+1999999

-848000

0

+1

-1

-1

+1

0

-848000

+1199999

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 10 of 51

4.3 Reset to factory settings

To return to the original condition of the device as delivered, there exist the following

options:

Access

Coding

Settings are restored for

CANopen

(See object 1011h:

Restore Parameter)

1011h

"load"

Sub-index 1

All parameters

Sub-index 2

Only bus parameters

Sub-index 3

Only CiA DS-406 parameters

Sub-index 4

Only manufacturer-specific parameters

Table 8: Access to factory settings

5Communication via CAN bus (CANopen)

The CANopen communication profile CiA DS-301 V4.2, the Device profile for Encoders CiA DS-

406 V3.2 as well as the indicator specification CiA DS-303 Part 3 V1.4.0 for CAN diagnosis

form the basis for the MSA501 CAN. The MSA501 supports device class C1 and partly C2. The

details required for a better understanding of the operation are included in this

documentation. If more in-depth information is required, we recommend the applicable

technical literature on CAN or CANopen.

5.1 Telegram structure

The data telegram of a CAN message consists of the following fields:

SOF

Identifier (COB-ID)

Control field:

Data field (max. 8 byte)

CRC

ACK/EOF

SOF:

(Start of Frame) start bit of the telegram

Identifier (COB-ID):

By means of the identifier, all bus subscribers check whether the message is relevant for

each of them.

The identifier determines the priority of the message. The lower the value of the identifier,

the higher is the priority of the message This enables preferential transmission of

important messages via the bus.

The Identifier field contains the identifier as well as bits for the recognition of the length of

the identifiers (11 or 29 bits). The device address, channel selection as well as data direction

are determined via the identifier as well.

Thus, the 11bit identifier (COB identifier) consists of a 4bit function code and a 7bit node

number.

Bit no.

10

9

8

7

6

5

4

3

2

1

0

Type

Functional code

Node number (Node ID)

Assignment

x

x

x

x

0

0

x

x

x

x

X

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 11 of 51

The following functional codes have been defined in the “Pre-defined Connection Set” (only

the functional codes used in the present device are shown):

Object

Functional code

Resulting COB-ID

Object

Page

Network management (NMT)

0000b

0

-

12

SYNC message

0001b

128d (80h)

1005h

27

Emergency message

0001b

128d (80h) + Node-ID

1014h

34

TPD01

0011b

384d (180h) + Node-ID

1800h

37

TPD02

0101b

640d (280h) + Node-ID

1801h

38

SDO (tx)

1011b

1408d (580h) + Node-ID

1200h

36

SDO (rx)

1100b

1536d (600h) + Node-ID

1200h

36

Heartbeat message

1110b

1792d (700h) + Node-ID

-

23

Node Guard message

1110b

1792d (700h) + Node-ID

-

22

Table 9: Overview of COB identifiers

Changes to COB IDs are only possible in the PRE-OPERATIONAL NMT status. First, the COB ID

must be switched invalid via bit 31 = 1b before it can be changed and reactivated.

The COB ID of the Sync object is an exception, where bit 30 must be = 0b to enable the COB

ID to be changed. As bit 30 cannot be set to 1b in the MSA501, the COB ID could be changed

at any time.

The node number (Node ID) (see also object 5F0Ah: Node-ID and baud rate Bus CAN) is

assigned once in every bus system with configuration of the master on MSA501. The node

numbers range from 1 to 127. Node ID = 0 is reserved and must not be used.

The adoption of a node ID or baud rate which was reset occurs only after re-initialization (see

chapter 5.2.1: Network management (NMT) services).

Ex works, the MSA501 is delivered with node number 1 (1h).

Control field:

contains bit-by-bit information concerning the number of user data and determines whether a

data frame or RTR frame (Remote Transmission Request frame) is concerned.

Data field:

contains up to 8 bytes of user data. The user data has a different meaning depending on the

channel selection.

CRC:

contains bits for error detection.

ACK/EOF:

The ACK/EOF field contains telegram acknowledgment bits as well as bits for determining the

end of a telegram.

For a detailed description of the telegram please refer to the applicable technical CAN

literature. For simplification purposes, only identifier (COB ID) and data field will be dealt

with in the subsequent telegram descriptions.

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 12 of 51

5.2 Node control

5.2.1 Network management (NMT) services

The master configures, manages and monitors network nodes via the NMT service. The device

is always in one of the four communication states “INITIALISATION”, “PRE-OPERATIONAL”,

“OPERATIONAL” or “STOPPED” (see Fig.. 5)

Power on oder Software Reset

Initialisation

CAN-Kommunikation

BootUp Message

1

2

2

3

3

4

4

4

1

Re-Initialisierung

CAN-Karte

5

55

Init

Fig.. 5: NMT Status diagram

5.2.1.1 NMT communication states

NMT Status INITIALISATION

The device is not involved in the events on the bus in this state. All hardware and software

components are initialized. This state is attained after switching on the device or after receipt

of the command code 81h (“Reset node”) of the own or global addresses. Following receipt of

the command code 82h (“Reset Communication”), the display will enter the initialization

stage as well. But only hardware and software associated with CAN communication will be

reinitialized. The device signals automatically the completion of initialization by sending a

boot-up message. As soon as the boot-up message was sent successfully, the device will enter

the “PRE-OPERATIONAL” status.

NMT Status PRE-OPERATIONAL

Parameterization data (SDO) can be exchanged in the pre-operational mode. However, no

process data (PDOs) is transferred.

NMT Status OPERATIONAL

The exchange of process data is enabled as well. However, COB-ID and Transmit PDO mapping

parameters can no longer be changed in this condition.

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 13 of 51

NMT Status STOPPED

Communication is stopped except for heartbeat and node guarding. Only NMT communication

is still enabled.

5.2.1.2 Toggling between the NMT communication states

For toggling between the communication states, telegrams with the following structures are

used

Change of state

Transition

in Fig.. 5

COB-

ID

Com-

mand

Node

ID

from

to

PRE-OPERATIONAL / STOPPED

OPERATIONAL

1d

0h

01h

x

OPERATIONAL/ PRE-OPERATIONAL

STOPPED

2d

0h

02h

x

OPERATIONAL / STOPPED

PRE-OPERATIONAL

3d

0h

80h

x

OPERATIONAL / PRE-OPERATIONAL /

STOPPED

INITIALISATION

(Reset Node)

5d

0h

81h

x

OPERATIONAL / PRE-OPERATIONAL /

STOPPED

INITIALISATION

(Reset Communication)

4d

0h

82h

x

Table 10: Toggling between communication states

If x = 0h is transferred as node ID, then the message is intended for all bus subscribers.

5.2.2 Boot-Up

The COB ID of the boot-up message is made up of 700h and the node ID. The “Initialisation”

NMT status is output as data content.

COB-ID

Byte 0

700h + Node-ID

00h

Table 11: Boot-Up message

5.2.3 SYNC object

CANopen enables the simultaneous query of all inputs and the simultaneous setting of all

outputs. The synchronization message (SYNC), a CAN message with high priority serves this

purpose. The identifier of the Sync object can be set via object 1005h (see 1005h: COB-ID

SYNC-Nachricht).

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 14 of 51

5.3 Process data exchange

5.3.1 Transfer of process data objects (PDO)

Process data objects (PDO) serve for fast exchange of process data. A maximum of 8 bytes of

user data can be transferred in a PDO. The MSA501 supports the Transmit PDO services TPDO1

and TPDO2 according to CiA DS-301 and CiA DS-406. The data content can be adjusted

individually via variable mapping.

5.3.1.1 Transmit PDO (from the MSA501 to the master)

PDO transfer from the display to the bus master (TPDO) can be initiated as a result of various

events:

asynchronous, controlled by an internal device timer

synchronous as a response to a SYNC telegram

as a response to an RTR message

When delivered, TPDO1 and TPDO2 are generated from the position value and the velocity

value. The transfer behavior of TPDO1 is determined via the objects 1800h, 1A00h and 6200h

and is assigned to asynchronous transmission. TPDO2 is defined via the objects 1801h and

1A01h and serves synchronous transmission.

The structure of the messages is shown in Table 12, with variable and changeable mapping

(see chapter 5.3.1.2 Variable TPDO mapping).

COB-ID

Process data in binary code

Byte 0

(LSB)

Byte 1

Byte 2

Byte 3

(MSB)

Byte 4

(LSB)

Byte 5

(MSB)

TPDO1

180h + Node-ID

Position value

Velocity value

TPDO2

280h + Node-ID

Table 12: TPDO message

Asynchronous data transmission (TPDO1)

If a TPDO1 is to be sent cyclically, then the cycle time must be entered in milliseconds into

object 1800h, sub-index 05h. The TPDO1 will not be sent if the value 0 ms is written. The

function is disabled. The minimum value to be set is 1 (= 1 ms). Alternately, the value can

also be written into the permanently internally linked object 6200h.

Synchronous data transfer (TPDO2)

As delivered, the device responds to every SYNC message received with the output of the

TPDO2 message. 1h is entered for synchronous transmission in object 1801h, sub-index 02h.

If a value n between 1d and 240d (= F0h) is entered, the device will respond to every nth

SYNC message.

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 15 of 51

RTR

Queries can be sent via RTR (see chapter 5.1: Telegram s, control field) to TPDO1 and TDPO2.

5.3.1.2 Variable TPDO mapping

By changing objects 1A00h and 1A01h you can specify the data content to be transferred in

the TPDOs. The maximum of 8 data bytes can be mapped in a TPDO.

Procedure of changing the TPDO mappings:

1. The device must be in the Pre-Operational NMT status.

2. By setting the COB-ID Valid bit to 1, the corresponding TPDO will be disabled.

3. Mapping is disabled by writing sub-index 00h to 0h.

4. Mapping is changed by writing into the desired sub-indexes the desired objects and the

data length.

5. In order to enable mapping, the maximally used sub-index must be entered in sub-index

00h.

6. The TPDO is reactivated by deleting the Valid bit of COB-ID on 0.

Example of changing a TPDO1 mapping:

Default setting:

Node ID: 1h

TPDO1: COB-ID 00000181h

Mapping:

1A00.0h 2

1A00.1h 60040020h (position value object 6004h, sub-index 00h, 32bit)

1A00.2h 60300110h (speed object 6030h, sub-index 01h, 16bit)

Desired mapping:

1A00.0h 3

1A00.1h 60040020h (position value object 6004h, sub-index 00h, 32bit)

1A00.2h 51220108h (Sys Register object 5122h, sub-index 01h, 8bit)

1A00.3h 51220208h (Flag 0 Register object 5122h, sub-index02h, 8bit)

1. User dataThe device must be in the Pre-Operational NMT status.

2. Disable TPDO1 via COB-ID = 80000181h.

COB-ID

User data

Command

Index L

Index H

Subindex

Data 0

Data 1

Data 2

Data 3

601h

23h

00h

18h

01h

81h

01h

00h

80h

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 16 of 51

3. Disable current mapping via 1A00.0h = 0.

COB-ID

User data

Command

Index L

Index H

Subindex

Data 0

Data 1

Data 2

Data 3

601h

23h

00h

1Ah

00h

00h

00h

00h

00h

4. Execute desired changes on mapping

COB-ID

Nutzdaten

Command

Index L

Index H

Subindex

Data 0

Data 1

Data 2

Data 3

601h

23h

00h

1Ah

01h

20h

00h

04h

60h

601h

23h

00h

1Ah

02h

08h

01h

22h

51h

601h

23h

00h

1Ah

03h

08h

02h

22h

51h

5. Enable mapping via 1A00.0h = 3.

COB-ID

User data

Command

Index L

Index H

Subindex

Data 0

Data 1

Data 2

Data 3

601h

23h

00h

1Ah

00h

03h

00h

00h

00h

6. Enable TPDO1 via COB-ID = 00000181h.

COB-ID

User data

Command

Index L

Index H

Sub-index

Data 0

Data 1

Data 2

Data 3

601h

23h

00h

18h

01h

81h

01h

00h

00h

5.4 Parameter data exchange

5.4.1 Transmission of Service Data Objects (SDO)

Service data objects serve mainly device configuration via the directory of objects. SDOs in

the expedited Request/Response and in the normal normal Request/Response are supported.

The identifier is set to 11 bits and cannot be changed.

Two SDO services are available:

SDO (rx) (Master MSA501): 600h + Node-ID

SDO (tx) (MSA501 Master): 580h + Node-ID

These SDO identifiers cannot be changed!

5.4.1.1 Expedited Request/Response

Except for reading the object 1008h: Manufacturer Device Name, all SDOs are exchanged

between two subscribers in the expedited Request/Response method. The user data is

provided already with the initialization message.

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 17 of 51

SDO messages are set up as follows:

COB-ID

User data in the Binärcode

Byte 0

read /

write

Byte 1

LSB

Byte 2

MSB

Byte 3

Byte 4

LSB

Byte 5

Byte 6

Byte 7

(MSB)

SDO rx/tx

+ Node-ID

Command-

byte

Index

Subindex

User data (Parameter)

Command byte, byte 0:

The command byte determines the type of access and the number of valid data bytes. The

following command bytes are valid for the MSA501:

Command byte

Type

Function

Write Request

23h

SDO (rx), Initiate Download

Request, expedited

Send parameter to slave

(All 4 data bytes valid)

Write Request

2Bh

SDO (rx), Initiate Download

Request, expedited

Send parameter to slave

(2Bytes of 4 data bytes valid)

Write Request

2Fh

SDO (rx), Initiate Download

Request, expedited

Send parameter to slave

(1Byte of 4 data bytes valid)

Write Response

60h

SDO (tx), Initiate Download

Response

Acknowledgment of data

acquisition to master

Read Request

40h

SDO (rx), Initiate Upload

Request

Request parameter from slave

Read Response

43h

SDO (tx), Initiate Upload

Response, expedited

Report parameter to master

(All 4 data bytes valid)

Read Response

4Bh

SDO (tx), Initiate Upload

Response, expedited

Report parameter to master

(2Bytes of 4 data bytes valid)

Read Response

4Fh

SDO (tx), Initiate Upload

Response, expedited

Report parameter to master

(1Byte of 4 data bytes valid)

Error Response

80h

SDO (tx), Abort Domain

Transfer

Slave reports error code to master

Table 13: Command coding

Index, bytes 1 and 2:

The index (object number) is entered in the user data byte 2 (low byte) and user data byte 3

(high byte) in the Intel data format. Here, the index of the object to be parameterized is

entered.

Sub-index, Byte 3:

The sub-index indicates the number of the fields for objects realized as an array.

User data (parameters), byte 4-7:

In the user data, the value of the parameter is entered in left-aligned Intel notation. Byte 4 =

low byte ... Byte 7 = high byte

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 18 of 51

5.4.1.2 Normal Request/Response

If more than 4 bytes of service data are to be transferred, the data is exchanged between two

subscribers via the normal Request/Response. This procedure is also initiated by an

initialization message, and the actual user data will be transferred in the subsequent segment

messages.

For the MSA501 this is only the case with reading of the object 1008h: Manufacturer Device

Name.

The initialization message has the following structure:

COB-ID

User data in binary code

Byte 0

read /

write

Byte 1

LSB

Byte 2

MSB

Byte 3

Byte 4

LSB

Byte 5

Byte 6

Byte 7

MSB

SDO rx/tx

+ Node-ID

Command

byte

index

Sub-index

User data (number of user data)

The segment message has the following structure:

COB-ID

User data in binary code

Byte 0

read /

write

Byte 1

LSB

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

MSB

SDO rx/tx

+ Node-ID

Command

byte

User data

Initialization and segment message: Command byte, byte 0:

The command byte determines the type of access and the number of valid data bytes. The

following command bytes are valid for the MSA501:

Command byte

Type

Function

Read Request

40h

SDO (rx), Normal Initiate

Upload Request

Request parameter from slave

(number of bytes to be

transferred).

Read Request

60h

SDO (rx), Normal Segment

Upload Request

Request parameter from slave (user

data)

Read Response

41h

SDO (tx), Normal Initiate

Upload Response

Report parameter to master

(number of bytes to be

transferred).

Read Response

03h

SDO (tx), Normal Segment

Upload Response

Report parameter to master (user

data)

Error Response

80h

SDO (tx), Abort Domain

Transfer

Slave reports error code to master

Table 14: Command coding

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 19 of 51

Initialization message : Index, Bytes 1 and 2:

The index (object number) is entered in the user data byte 2 (low byte) and in the user data

byte 3 (high byte) in the Intel data format. Here, the index of the object to be configured is

entered.

Initialization message : Subindex, Byte 3:

The sub-index indicates the number of the fields for objects realized as an array.

Initialization message : User data (Parameter), Byte 4-7:

In the service data range, the value of the parameter is entered in left-aligned Intel notation.

Byte 4 = low-Byte ... Byte 7 = high Byte

Segment message : User data (Parameter), Byte 1-7:

In the user data range, the value of the parameter is entered in left-aligned Intel notation.

Byte 1 = low-Byte ... Byte 7 = high Byte

5.4.1.3 Error Response in SDO exchange

With invalid access, an error message (Abort) is returned to the master.

The error codes are described in the CANopen profile (CiA DS-301) or in the encoder profile

(CiA DS- 406), respectively. The table below shows the error codes used:

Error code

Description

05030000h

Toggle bit unequal in Normal Transfer of Request/Response.

06010000h

Wrong access to an object.

06010001h

Read access to Write-Only.

06010002h

Write access to Read-Only.

06020000h

Object doesn’t exist in the object directory.

06040041h

Object cannot be mapped to PDO.

06040042h

The number and lengths of the objects to be mapped exceed PDO

length

06090011h

Sub-index does not exist

06090030h

Wrong value range of selected parameter.

08000020h

Parameters cannot be transferred to application or stored.

08000022h

Parameters cannot be transferred to application or stored due to the

current device status.

08000024h

No data available

Table 15: Error codes

Communication via CAN bus (CANopen)

MSA501 Date: 12.10.2018 Art. No. 88734 Mod. status 330/18 Page 20 of 51

5.4.1.4 SDO examples

Example of reading SDO parameters with the expedited Request/Response:

The calibration value stored in object 6003 of the directory of objects is to be read from the

slave with device address 1h.

Calculation of the identifier: 600h + Node-ID = 600h +1h = 601h

Command 40h

Index: 6003h

Sub-index: 00h

The current value is 510d = 01FEh

Request of master from slave with node ID 1h:

COB-ID

User data

Command

Index L

Index H

Subindex

Data 0

Data 1

Data 2

Data 3

601h

40h

03h

60h

00h

x

x

x

x

Response to the request by the slave:

Calculation of the identifier: 580h + Node-ID = 581h

COB-ID

User data

Command

Index LB

Index HB

Subindex

Data 0

Data 1

Data 2

Data 3

581h

43h

(4 Bytes

gültig)

03h

60h

00h

FEh

01h

00h

00h

Example of writing SDO parameters with the expedited Request/Response:

The calibration value stored with 2 bytes in object 6002 of the directory of objects is to be

changed in the slave with device address 1h.

Calculation of the Identifier: 600h + Node-ID = 600h + 1h = 601h

Command: 2 bytes are to be written 2Bh

Index: 6200h

Subindex: 00h

The new value shall be 4500d = 1194h

Writing of a value from master to slave with node ID 1h:

COB-ID

User data

Command

Index L

Index H

Subindex

Data 0

Data 1

Data 2

Data 3

601h

2Bh

(2 Bytes

gültig)

00h

62h

00h

94h

11h

00h

00h

Response to the command by the slave:

Calculation of the identifier: 580h + Node-ID = 580h + 1h = 581h

COB-ID

User data

Command

Index L

Index H

Subindex

Data 0

Data 1

Data 2

Data 3

581h

60h

00h

62h

00h

00h

00h

00h

00h

Other manuals for MSA501

1

Table of contents

Other Siko Controllers manuals

Popular Controllers manuals by other brands

Hobby-Wing

Hobby-Wing FLYFUN 40A V5 user manual

Pegasus Astro

Pegasus Astro Dual Motor Focus Controller manual

GM International

GM International D1048S instruction manual

Vivo Link

Vivo Link VLHDMICTL1-MME user manual

Timeguard

Timeguard ProgramaSTAT UFPT24 operating instructions

GSM Activate

GSM Activate SWV2G-RS2 manual

InnoMedia

InnoMedia ESBC 9378-4B Quick install guide

Asahi KASEI

Asahi KASEI AK4458 General description

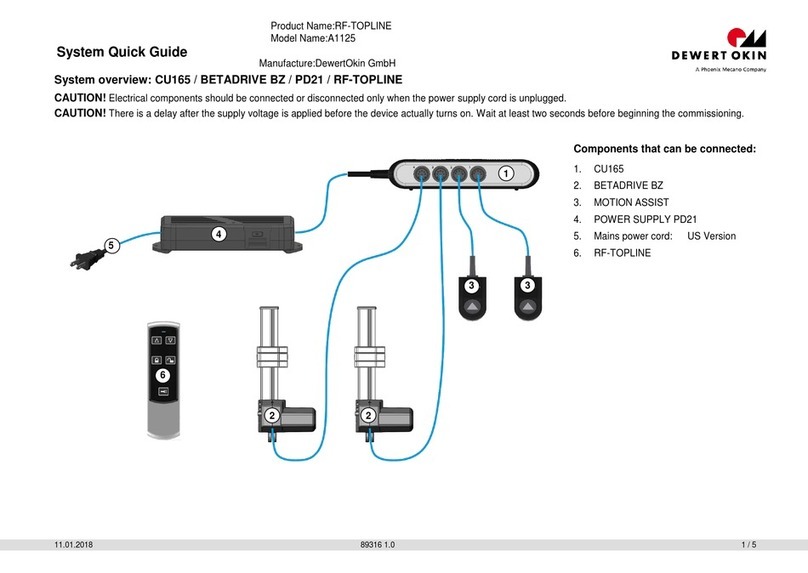

dewert okin

dewert okin A1125 quick guide

Metropolitan Industries

Metropolitan Industries Sump Boss BP2000 Installation & service manual

Winpower

Winpower SWS Series user manual

Elmo

Elmo Gold Lion 100 installation guide