m

- After these operations, if you do not wish to programm this transmitter as the first point of individual

control of the motor,, switch off the power to the receiver. If you want to programm a new transmitter (e.g

after the shutter is installed) with this receiver, go to the procedure 4.1. and then move on to operation 5.

mIf you switch off the power to several receivers, they will all be in cancelling mode. That is why,

you must “eject” out of this mode all the receivers that are not to be deprogrammed by sending

a command from their individual control transmitter (UP or Down).

m- This operation can only be performed from the transmitter that was used for operation 4.1.

- Press the transmitter “PROG” Key for

approximately one second. The motor will run

for a half a second in one direction and then in

the other.

Your transmitter is now programmed

to control the Hz.02 motor in stable mode.

9.1

- Switch off the power supply to the motor for 2 seconds.

- Switch on the power supply to the motor for 7 seconds.

- Switch off the power supply to the motor for 2 seconds.

- Switch the power to the motor back on. The

motor will run for 5 seconds in random direction

and is now in the “cancelling” mode.

1- Position the motor on the UP end limit by using the keys UP or DOWN.

2- To memorize the UP end limit position, press simultaneoulsy the keys STOP and DOWN. The motor will run

automatically in the DOWN direction.

3- When the motor arrives on the DOWN End limit, press the key STOP.

4- If necessary adjust the position with the keys UP or DOWN.

5- To memorize the DOWN end limit position, press simultaneoulsy the keys STOP and UP. The motor will run

automatically in the UP direction.

6- Press 2 seconds the STOP key to validate the setting. The motor will stop, and will run for half a second in

one direction, then in the other direction.

7.1 : Open the memory of the receiver from

the control transmitter:

- Press the “PROG” key of the transmitter for

about three seconds. The motor will run for a

half a second in one direction, then in the other.

7.2 : Validate the operation from the new

transmitter you want to programm:

- Press the “PROG” key of the transmitter for

about one second. The motor will run for a half

a second in one direction, then in the other.

- Press the “PROG” key of the transmitter more

than 7 seconds. Maintain the pressureuntil the

motor will first run for a half a second in one

direction and then the other, and a few second

later, it will run again in both direction.

9.2 - Then, validate the cancelling of the affected motor from the individual control:

- For group controls, repeat operations 7.1 and 7.2 for each motor in the group.

- For main controls, repeat operations 7.1 and 7.2 for each motor in the installation.

- To delete an transmitter from the memory of a motor, perform operations 7.1 with a

programmed transmitter, then perform the operation 7.2 with the transmitter to be

deleted.

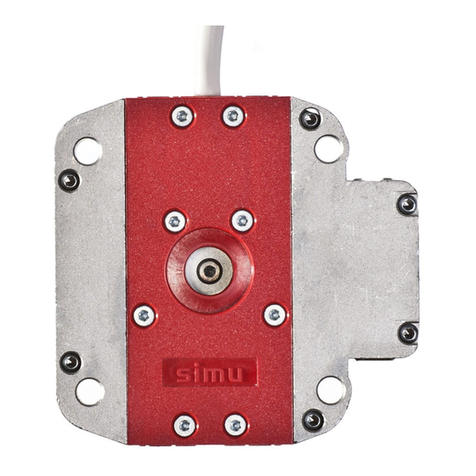

Hereby, SIMU, declares that this equipment “T5Hz.02” is in compliance with the essential

requirements and other relevant provision of Directive 1999/5/EC. A declaration of Conformity is

available at the web address: www.simu.fr, heading “Normes”. Usable in EU,

The Hz.02 motor is now as it was originally configured, and no transmitter and no settings is saved

in its memory and is ready for a new programming.

3/4 4/4

Recording and controling intermediate position

6

Programming a new (individual, group or main) control point:

7

Programming the first individual point of control

5

Cancelling programming and settings

9

Recording :

- Position the motor on the

wanted position.

- Press 5 seconds on the “stop”

key. The motor will run for

1/2 second in one direction

and then in the other.

Controling :

- Press on the “stop” key for

0,5s. the motor goes to the

intermediate position.

Re-adjustement of end limits

8

8.1 : Re-adjustement of UP end limits

8.2 : Re-adjustement of DOWN end limits

1- Position the motor on the UP end limit previously

set in §4.3 with the UP key.

2- Press simultaneously for 5 seconds the UP and

DOWN keys, The motor will run for a half a second

in one direction and then in the other direction.

3- Adjust the new position with the UP and DOWN

keys.

4- Validate the new position by pressing 2 seconds

the STOP key. The motor will run for a half a

second in one direction and then in the other

direction. The new end limits setting is memorized.

1- Position the motor on the DOWN end limit

previously set in §4.3 with the DOWN key.

2- Press simultaneously for 5 secondes the UP and

DOWN keys, The motor will run for a half a second

in one direction and then in the other direction.

3- Adjust the new position with the UP and DOWN

keys.

4- Validate the new position by pressing 2 seconds

the STOP key. The motor will run for a half a

second in one direction and then in the other

direction. The new end limits setting is memorized.