1

FormA900

Date3-02/A

Page 1 of 4

Printed In U.S.A.

INSTRUCTIONS & PARTS LIST

FOR1446HPLAIRSHEAR

AIRSUPPLY

Theefficiencyandlifeofthistooldependsonthepropersupplyof

clean,dry,lubricatedairatabout90Ibs.P.S.I.,althoughhigheror

lower pressures may be used. The use of an air line filter,

pressureregulatorandlubricatorisrecommended.

Beforeconnectingthetool,blowtheairlinetoremovewaterand

dirtwhich may haveaccumulated. This isespecially important for

a new line or when the line has not been used for some time.

HOSEANDHOSECONNECTION

Theair supply hoseis 3/8" I.D.If extension hoseis necessary,

use1/2" hose, withcouplings not lessthan 3/8" I.D.

LUBRICATION

Anoilsupplytothe air motor isimportant.SIOUXairlinelubrica-

torsarerecommended.Adjust to deliver2dropsofSIOUXAir

MotorOilNo.288 per minute. Whenairlinelubricatoris not used

squirtseveraldrops of oil intotheair inlet before using.Gearcase

andShearheadmust be lubricated afterevery40hours of

operationwithSIOUXGreaseNo.289A.

SAFETY

1. Keepworkarea clean

2. Donot force tool.

3. Secure work were possible—use clamps or vise.

4. Keeptoolssharpandingoodshape.

5. Disconnect tools when not in use.

6. The use of accessories not provided or specified may be

hazardous.

7. Usegoggles or safety glasses.

WARNING

Designedto cut onlyup to 16gauge steel; plasticand associated

materialsupto 3/32"thick.Failuretogreasecould voidwarranty.

SiouxToolscannot assume responsibility fordamagetoor

malfunctionofashearheadusedincombinationwithanydrill

otherthanthoseregularlysuppliedbySiouxTools.

SHEAR HEAD MAINTENANCE INSTRUCTIONS

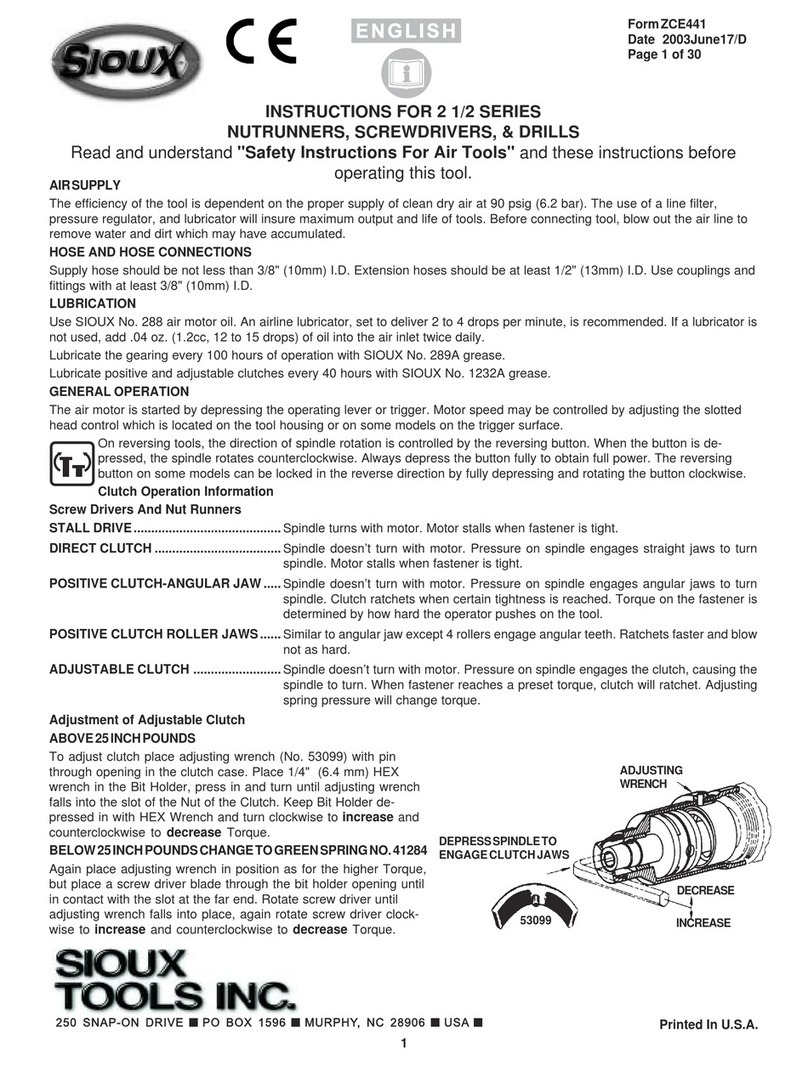

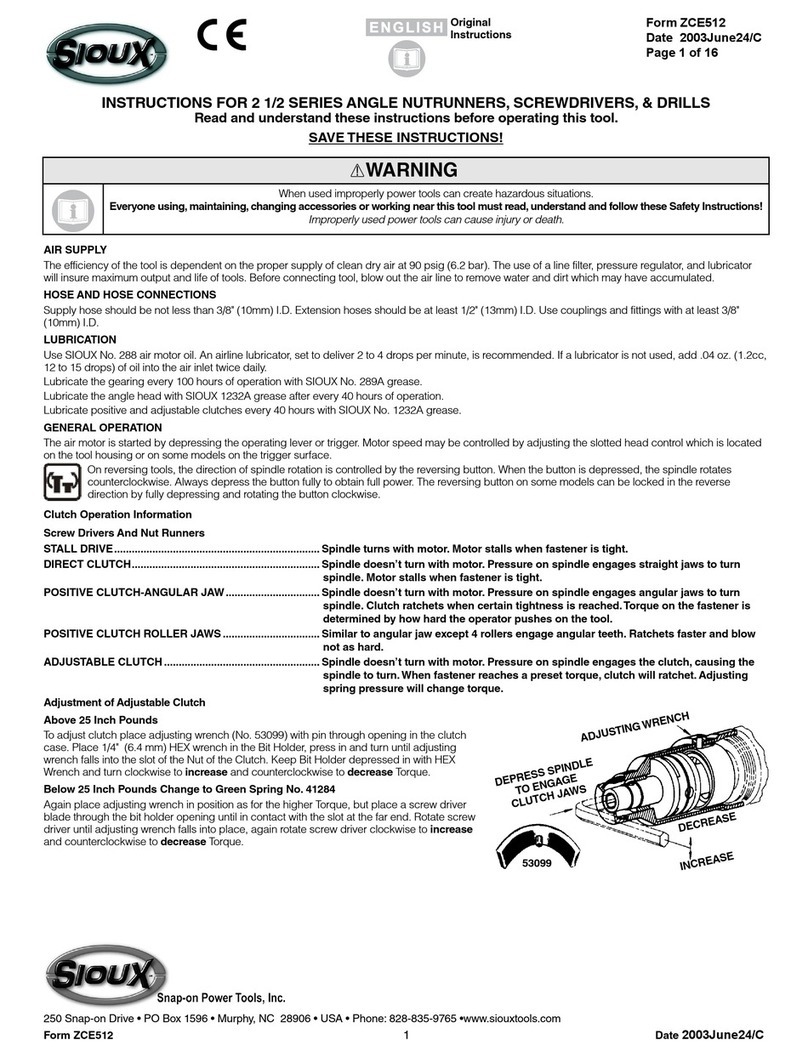

ADJUSTMENT

Toadjust the curl of wastematerial, the leftside knife 54500 has

elongatedholes.Adjustmentmaybenecessaryafterchanging

blades or material being cut. Loosen cap screws 07102 and tap

sideknife 54500 either forward orbackward so that curl ofwaste

doesnothitshearhousing12598orworkmaterialwhilecutting.

DISASSEMBLY

Toremove53609shearheadfrompowerunitand dismantle:

1. Loosen both rear cap screws 07102 three complete turns.

2. Removeshearheadassembly53609frommotorbypulling

headfirmlyforward.Slighttwistingactionmayberequired.

3. Remove three cap screws 07102 completely from shear

housing 12598. Be careful not to lose rear spacer bushing

54502when removing rear cap screw.

4. Remove center blade 54499 from shear housing 12598 by

tappingbladegentlyrearward.Becarefulnottolosespacer

bushing54502fromholeincenterblade.

5. Side knives 54500 and 54501 will now drop out of shear

housing.

ASSEMBLY

Toassemble53609shearheadandadapttopowerunit:

1. Place the left side knife 54500 into position in the shear

housing.

2. Insert center cap screw 07102 through housing and blade

justfarenoughtoslipspacerbushing54502overcapscrew.

3. Placerightsideknife54501intopositionandpushcentercap

screwthroughrightsideknife.Startcapscrewintoinsertjust

enoughtoholdbladesinplace.DONOTTIGHTEN.

4. Insertspacerbushing54502intoholeincenterblade54499

andlubricate withagoodgradeofbearinggrease.

5. Install center blade 54499 into shear housing 12598 by

tapping blade gently forward using a drift to line up hole in

centerbladewithforwardholesinhousing.

6. Insert and tighten forward cap screw 07102 making sure

spacerbushing54502incenterbladestaysinposition.Apply

good grade of bearing grease to clevis in center blade.

WHEN SHEAR HEAD IS PROPERLY ASSEMBLED THE

CENTERBLADEWILLPIVOTFREELYINHEAD.

7. Insertrearcapscrew07102intoshearhousing12598butdo

notcompletelytighten.

Toinstallshearhead assembly 53609ontopowerunit:

1. Makesurerearcapscrewandcentercapscrew07102are

loosenedthreecompleteturns.

2. Place shear head onto unit and tighten cap screws 07102

snuglytolockheadassemblyinplace.Itmaybenecessary

togentlytaptheshearheadassemblyintoplaceifitdoesnot

readilyslipontothepowerunit.