Form

#

Z518A

Model

5566

Date

5-99IB

7

314"

(20

mm)

Belt

Sander

IMPORTANT

Readthese instructionscarefullybeforeinstalling,operating,servicing

or

repairingthis

tool.

Keep

these instructionsin a safe,accessibleplace.

1

SAFETY

MESSAGES

1

A

WARNING

Operator Instructions

--

--

-.

Safety

rules

when

using

a

5566

Belt

Sander

Personal SafelyEquipment

Use

-

Safety

Glasses

YES

Use

-

Safety Gloves

Use

-

Safety

Boots

Use

-

Breathing

Masks

YES

Use

-

Ear Protectors

-

Always wear safety goggles.

-

Donot use as a grinder.

-

Useaccessoriesratedfor atleast

2,000

rnlmin.beltspeed.

-

Prolongedexposure to vibrationmay cause injury.

-

Readallinstructionsbeforeusingthistool. All operators must

befullytrainedinitsuseand aware of these

safety

rules.

-

Do notexceed the maximumworking air pressure.

-

Use personalprotectionequipment as recommended.

-

Usecompressedaironly atthe recommendedconditions.

-

If the tool appears to malfunction, remove from use

immediatelyand arrangefor serviceandrepair.If itisnot

practicaltoremovetoolfrom service,then shut off the air

supply to the tool and write or have written a warning

noteand attachitto thetool.

-

If tool is to beusedwith a balancer or other suspension

device, ensure that the tool is firmly attached to the

suspension/supportdevice.

-

When operating the tool, always keep the body and

particularlythehandsawayfromtheworkingattachment

fixed to the tool.

-

The tool isnotelectricallyinsulated.Neverusethetool if

there is any chance of coming into contact with live

electricity.

-

Always when usingthe tool, adopt a firm footing and/or

position and grip the tool sufficiently only to overcome

any reaction forces that may resultfrom the tool doing

work. Do notovergrip.

-

Useonly correctsparepartsfor maintenanceand repair.

Do

not improvise or make temporary repairs. Major

servicing and repairs should only be carried out

by

personstrained to do so.

-

Donotlock, tape, wire, etc.the'Or!/Off'

7

supplytothe tool can beshutoff inan emergency.

-

Check hose andfittingsregularlyfor wear.

-

Take care against entanglementof the moving parts of

the tool with clothing, hair, ties, cleaning rags, rings,

jewelry,watches,bracelets,etc.This couldcausethebody

or partsof the bodyto be drawn towardsand in contact

with the moving parts of the tool and could be very

dangerous.

-

It is expected that users will adopt safe working

practices and observe all local, regional or country

legalrequirementswhen installing, using or maintaining

the tool.

-

Take carethat the exhaustair doesnot pointtowards any

other person or material or substance that could be

contaminatedby oil droplets.Whenfirst lubricating

a

tool

or if the tool exhaust has

a

highoil content,do notallow

theexhaustairto come nearvery hot surfaces or flames.

-

Neverlaythe tooldown untiltheworking attachmenthas

stoppedmoving.

-

When the tool is not in use, shut

off

the air supply and

press throttle triggertlever to drainthe supply line. If the

tool is notto be usedfor

a

periodof time, first lubricate,

disconnectfromairsupplyandstore inadryaverageroom

temperatureenvironment.

-

If

the tool is passedfrom one user to a new or inexperi-

enceduser, makesuretheseinstructionsare available to

be passedwiththe tool.

-

Do not remove any manufacturer fitted safety devices

where fitted, i.e., wheel guards, safety trigger, speed

governors, etc.

I

-

Always Read InstructionsBefore

a

Using PowerTools

@

AlwaysWear Safety Goggles

@

Wear HearingProtection

Avoid ProlongedExposure

To Vibration

valve in 'On' position. The throttle

trigger/lever, etc. must always be

free

!o return

to

the

'Off'

position when

released.

-

Alwaysshutoff the airsupplytothetool

andpressthe'OnJOff' valve toexhaust

the air from the feed hose before

fitting, removing or adjusting the

working attachmentfittedto the tool.

-

Beforeusingthe tool, makesurethat a

shut off device has been fitted to the

supply tine and the position is known

and easily accessible so that the air

Includes;

Safety

Rules

Foreseen

Use

Work

Stations

PuttingIntoService

Operating

Dismantling

and

Assembly.

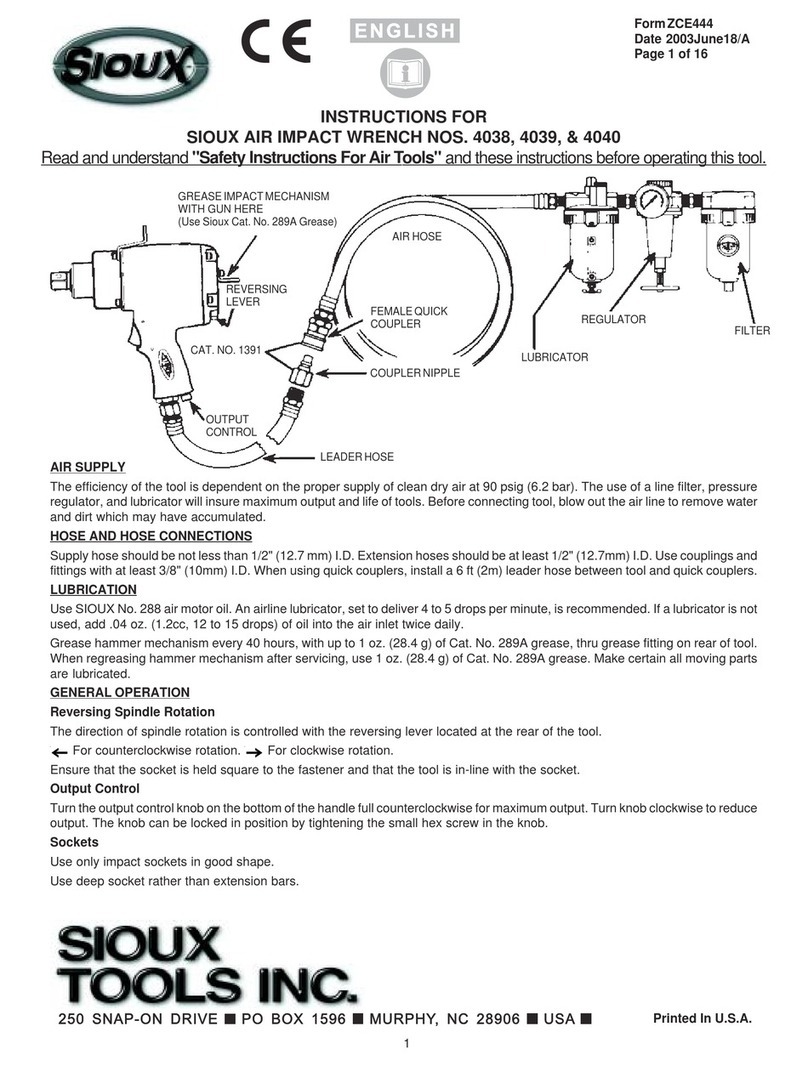

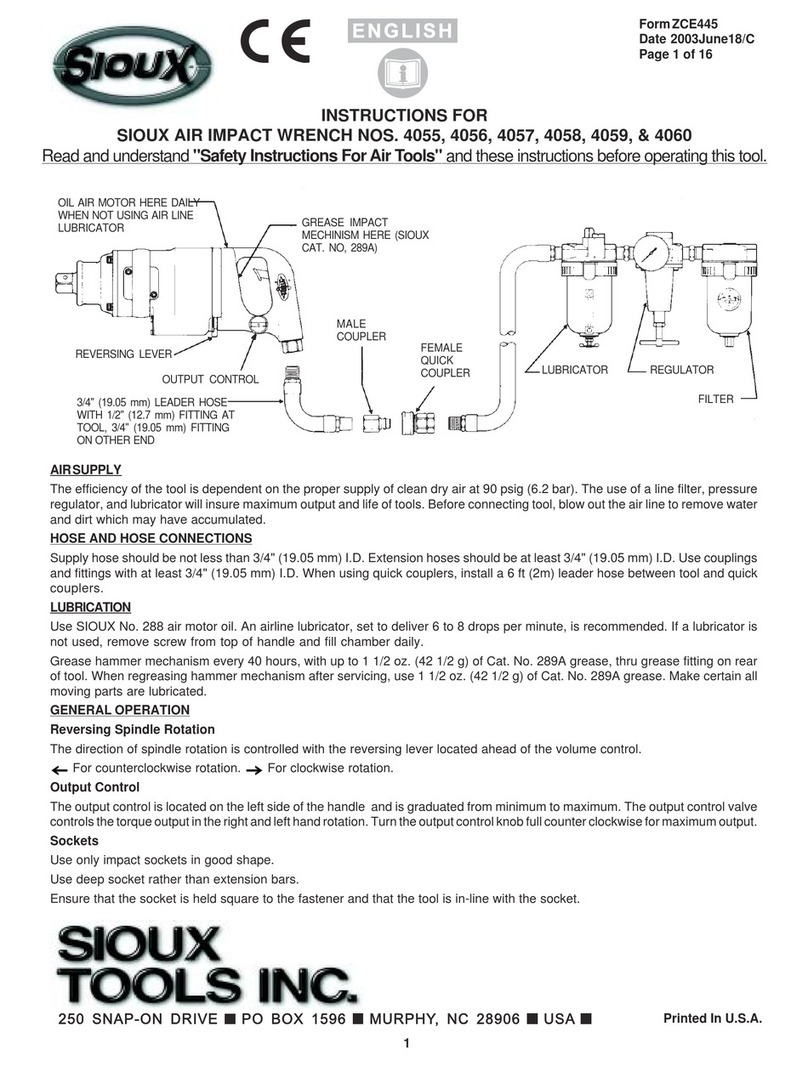

All PipeAnd Fittings

Should Be

112'

Or

Larger

with

SufficientCapacity

To Maintain Recommended

Easy

To

ReachAnd

Air

Tool

Operate!

Shut

Oil

Valve

Recommended

Air

Supply

System Figure