63 22 700 D 3344

14 D 3344.201.01.25.23 01.2011

4 Safety Sirona Dental Systems GmbH

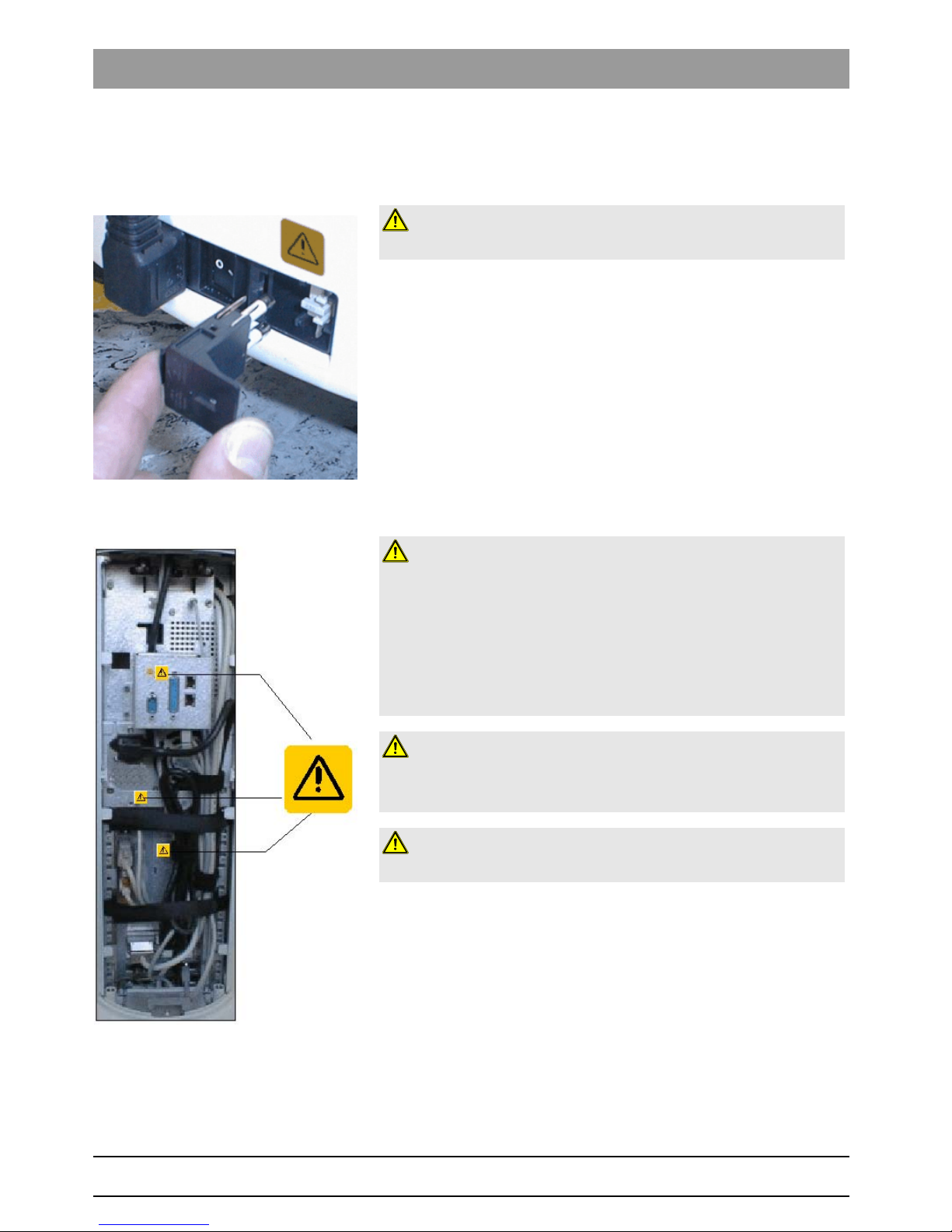

Electrostatic charges Operating Instructions for the Acquisition Unit CEREC 3

4.3.2 ESD protective measures

ESD ESD stands for ElectroStatic Discharge.

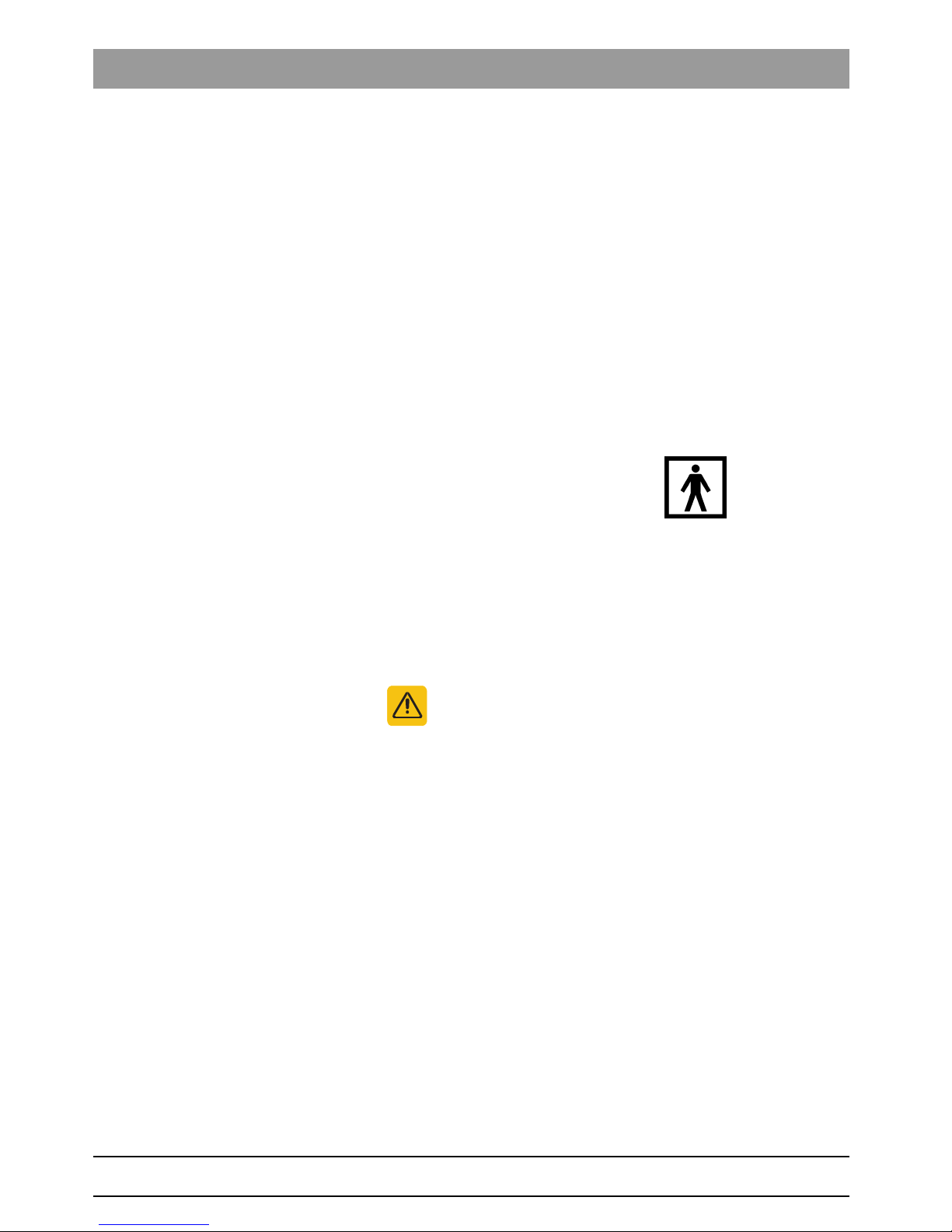

Training We therefore recommend that all persons working with this system be

instructed on the significance of this warning label. Furthermore, they also

should receive training in the physics of electrostatic discharges which can

occur in the practice and the destruction of electronic components which may

result if such components are touched by electrostatically charged USERS.

The content of this training is explained in the Chapter "About the physics of

electrostatic charges" [14].

4.3.3 About the physics of electrostatic charges

What is an electrostatic charge? An electrostatic charge is a voltage field on and in an object (e.g. a human

body) which is protected against conductance to ground potential by a

nonconductive layer (e.g. a shoe sole).

Formation of an electrostatic charge

Electrostatic charges generally build up whenever two bodies are rubbed

against each other, e.g. when walking (shoe soles against the floor) or driving

a vehicle (tires against the street pavement).

Amount of charge The amount of charge depends on several factors:

Thus the charge is higher in an environment with low air humidity than in one

with high air humidity; it is also higher with synthetic materials than with

natural materials (clothing, floor coverings).

The following rule of thumb can be applied to assess the transient voltages

resulting from an electrostatic discharge.

An electrostatic discharge is:

zperceptible at 3,000 V or higher

zaudible at 5,000 V or higher (cracking, crackling)

zvisible at 10,000 V or higher (arc-over)

The transient currents resulting from these discharges have a magnitude of

10 amperes. They are not hazardous for humans because they last for only

several nanoseconds.

Background Integrated circuits (logical circuits and microprocessors) are used in order to

implement a wide variety of functions in dental/X-ray/CEREC systems.

The circuits must be miniaturized to a very high degree in order to include as

many functions as possible on these chips. This leads to structure

thicknesses as low as a few ten thousandths of a millimeter.

NOTE:

Electrostatic discharge must be preceded by electrostatic charging.