Industrial Clean Basic Instruction manual

606/06/2016 Rev:2.0.0

CENTRAL VACUUMSYSTEMS ByTecnoplus s.r.l.

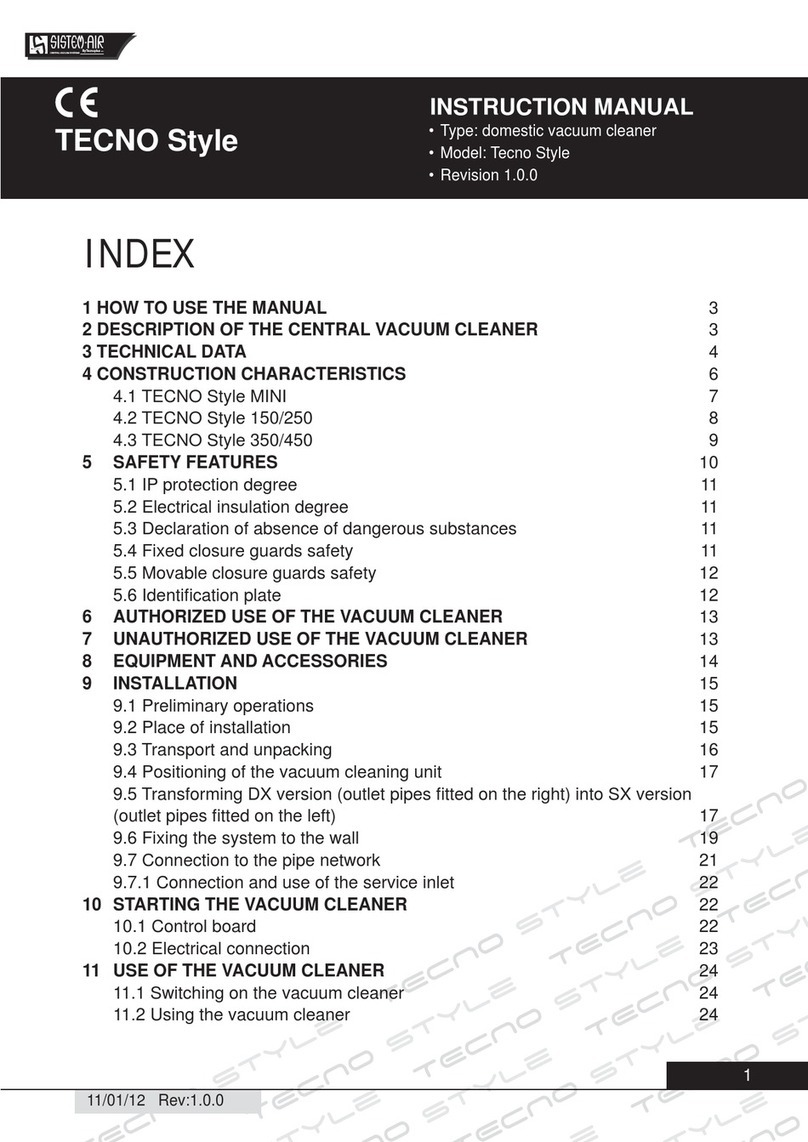

5 - SAFETY FEATURES

It is recommended to read carefully all the installation, use and maintenance instructions detailed

in this manual.

Furthermore, the following WARNINGS should always be observed:

• Never use the machine for unauthorized purposes.

• Keep children away from the vacuum cleaner when functioning. Children should not play with the

machine nor with the suction sockets.

• This equipment should not be used by persons (including children) with reduced psychic, sensory or

mental capacities or by persons with no experience or knowledge of the system, unless under the

guidance or instructed to use the machine by persons responsible for their safety.

• Children must always be supervised to ensure they do not play with the machine.

• Wear protective gloves and mask to carry out maintenance, to empty the dust bin or replace and clean

the filter.

• Only use original spare parts and accessories.

• Do not suction clean fabrics, heavy materials, ashes or hot embers.

• Never suction clean liquids

• Do not use the system without a filter cartridge.

• Do not block the exhaust air pipes or the motor cooling intakes.

• No part of the body should come into contact with the suction accessories.

• Do not suction clean building materials (concrete, lime wastes, plaster dust, etc.) once the installation

is completed. This will quickly clog the filter cartridge.

•Do not vacuum any material which may cause electrostatic charges in the piping system, if not

previously communicated to the constructor.

Finally, remind that pictograms or danger and warning signals can be found on those parts of the

equipment where, if not strictly followed, potential risky situations may occur.

WARNING: TECNOPLUS S.R.L. declines any form of responsibility or guarantee if the purchaser, or

anyone in his stead, makes even the slightest modification or adjustment to the purchased product.

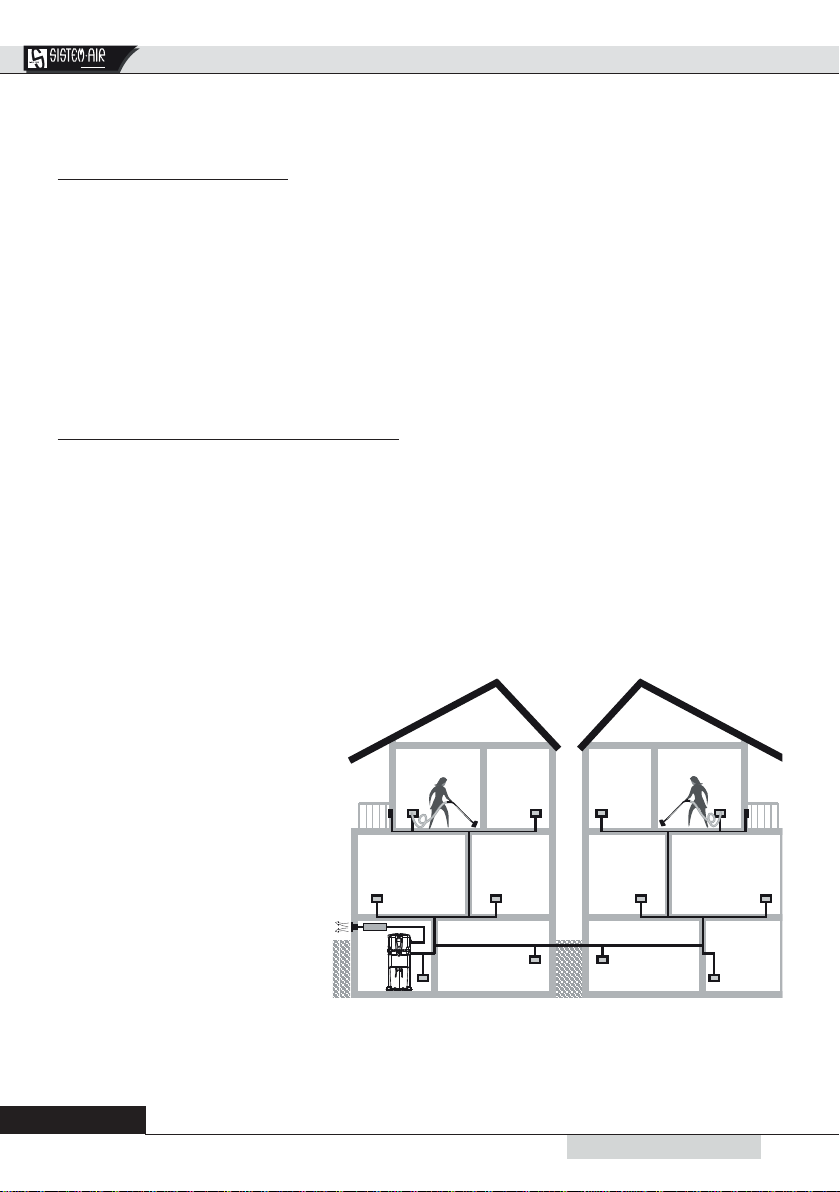

The unit has been designed to satisfy at best the present needs of the domestic central vacuum clean-

ers

market, both in terms of quality and operating capacity.

All materials and components used to manufacture this product comply with CE safety regulations. All

relevant certifications are held at TECNOPLUS S.R.L. headquarters.

5.1 Declaration of absence of dangerous substances

TECNOPLUS S.r.l. declares that its products and appliances have been manufactured with materials

which comply with the restrictions established by the health and environment protection regulations in

force and do not contain SVHC-classified substances (Substance of Very High Concern) in compliance

with CE regulation 1907/2006 (REACH: i.e. Registration, Evaluation, Authorization and Restriction of

Chemical Substances).Although these substances have not been used during the processing cycles of

raw materials and during the manufacturing cycles of our products, their presence in p.p.m. (parts per

million) cannot be completely excluded due to micro-pollution of raw materials.