Technical manual Revo Block Professional

10

06/06/2016 Rev:2.0.0

CENTRAL VACUUM SYSTEMS ByTecnoplus s.r.l.

5 - SAFETY FEATURES

It is recommended to read all the installation, use and maintenance instructions detailed in this manual

carefully.

Furthermore, the following WARNINGS should always be observed:

• Never use the machine for unauthorized purposes;

• Keep children away from the vacuum cleaner when functioning. Children should not play with the

machine nor with the suction sockets;

• This equipment should not be used by persons (including children) with reduced sensory or mental

capacities, or by persons with no experience or knowledge of the system, unless under guidance, or

instructed to use the machine by persons responsible for their safety;

• Children must always be supervised to ensure they do not play with the machine;

• Immediately disconnect from power supply if:

- the electric cable is damaged or worn;

- the vacuum cleaner has been exposed to rain or excessive humidity;

- the vacuum cleaner has been knocked, or the outer body has been in any way damaged;

- you think the system requires maintenance or repair;

• Wear protective gloves and mask to carry out maintenance, to empty the dust bin or replace and clean

the lter;

• Only use original spare parts and accessories;

• Do not suction clean fabrics, heavy materials, ashes or hot embers;

• Never suction clean liquids;

• Do not use the system without a lter cartridge;

• Do not block the exhaust air pipes or the motor cooling intakes;

• No part of the body should come into contact with the suction accessories;

• Use only one suction socket at a time;

• Do not leave the system switched on when not using it and disconnect it from power supply when the

system is not to be used for a long period of time;

• Do not suction clean building materials (concrete, lime wastes, plaster dust, etc.) once the installation

is completed. This will quickly clog the lter cartridge.

Finally, remind that pictograms, or danger and warning signals can be found on those parts of the equip-

ment where, if not strictly followed, potential risky situations may occur.

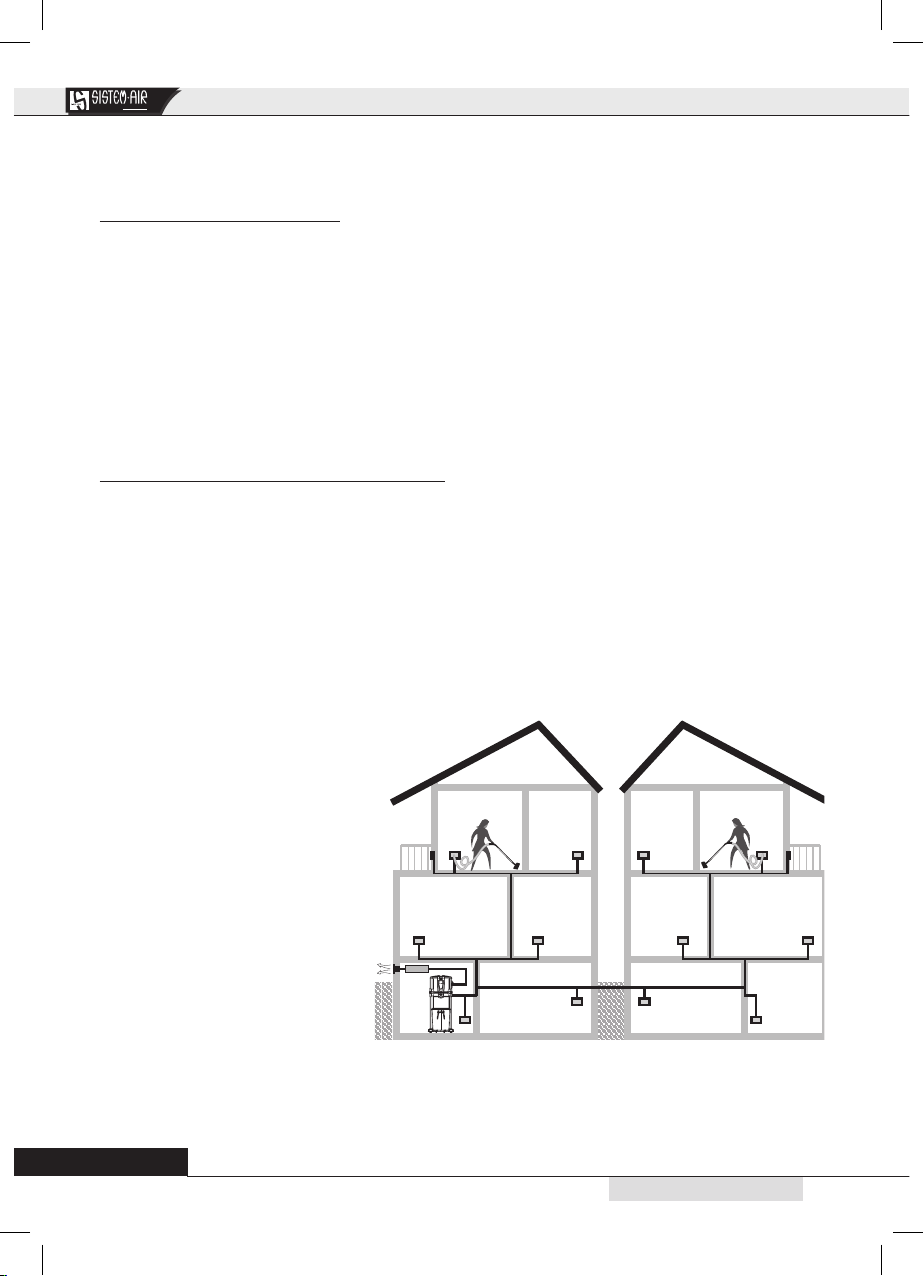

- High performing professional motor group with side-channel blow made of light alloy, no maintenance

needs, compliant with CE regulations, IP55 class, provided with integrated silencer.

- Motor noise dB(A): from 60 db (50 Hz), to 72 db (60 Hz).

The machine adopts an innovative control and routine maintenance system based on an electronic

control board with microchip, connected to pressure sensors and programmed to interact easily and

immediately with the user. Maintenance can be individually programmed by the user who will receive

messages about the machine status directly on a user-friendly graphic display, as well as suggestions

about actions to be taken in case of malfunctioning.

Moreover Sistem Air produced software, which displays all the information about system functioning,

once it is installed on a personal computer through the connection of an ethernet net cable and its

interface board (on request).