Contents

Explanation of signal words for safety 2

Safety ......................... 2

Owner/operator responsibility ...... 3

Intended use .................... 3

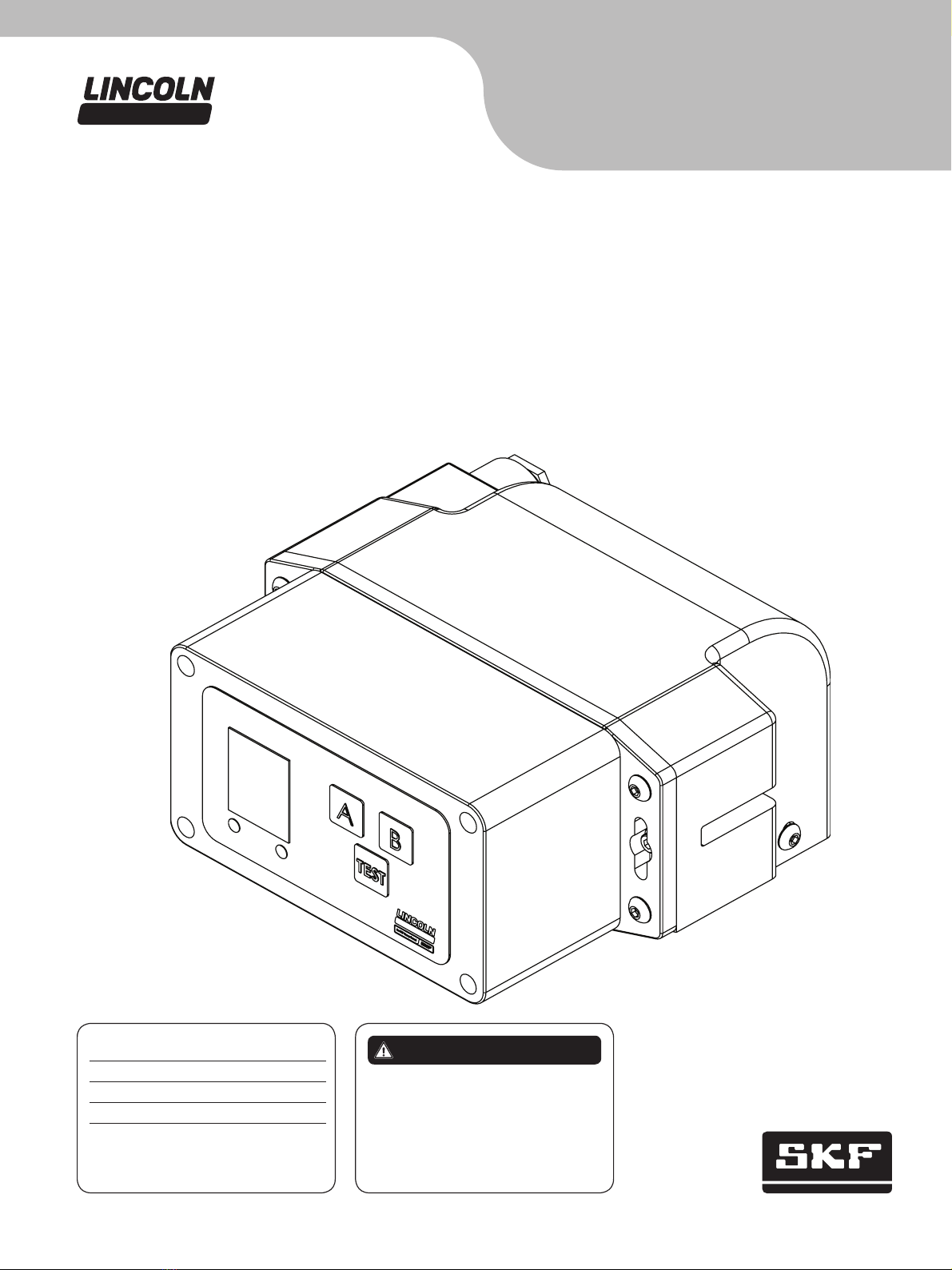

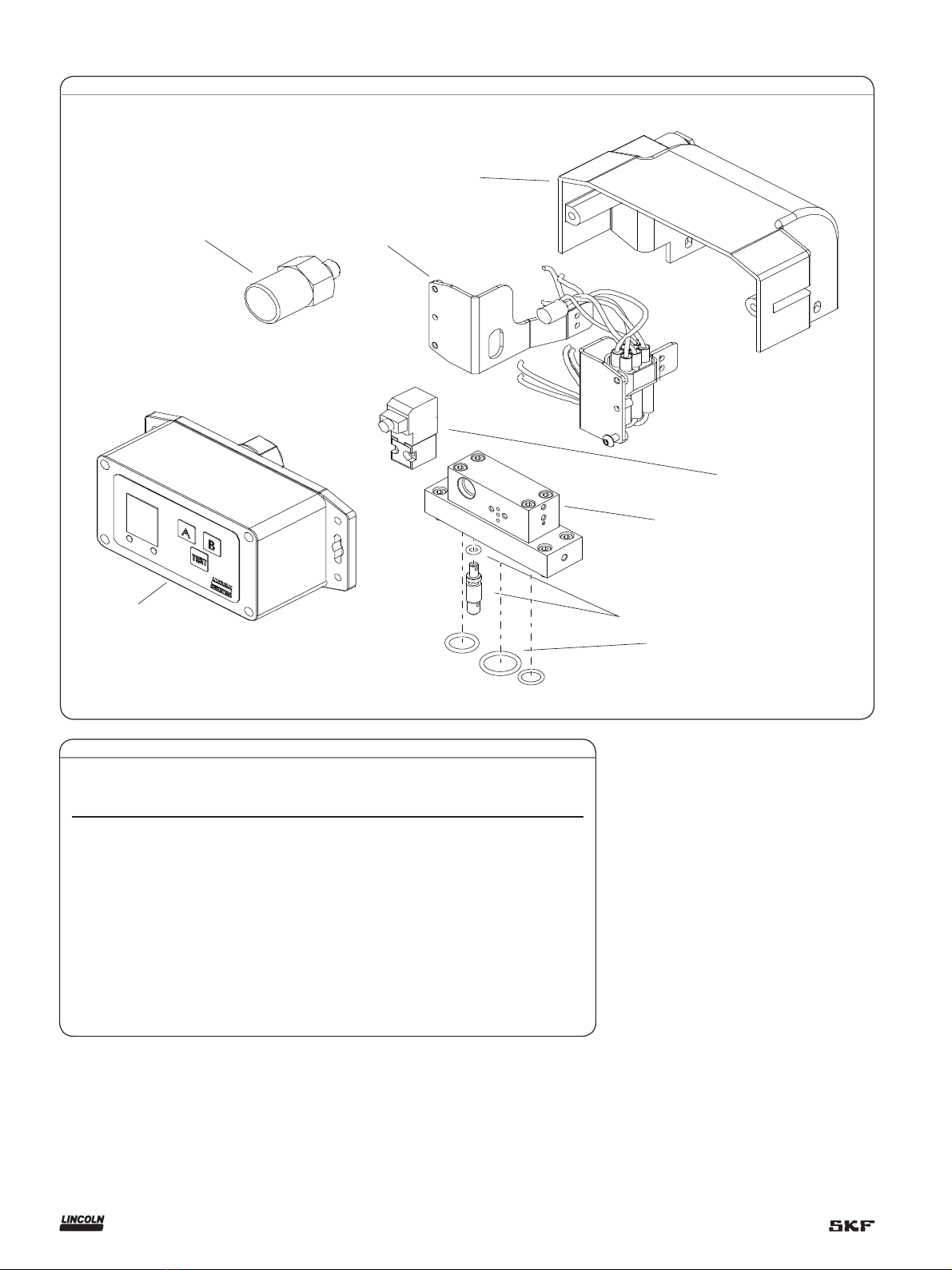

System overview ................ 3

Description ..................... 3

Specifications ................... 3

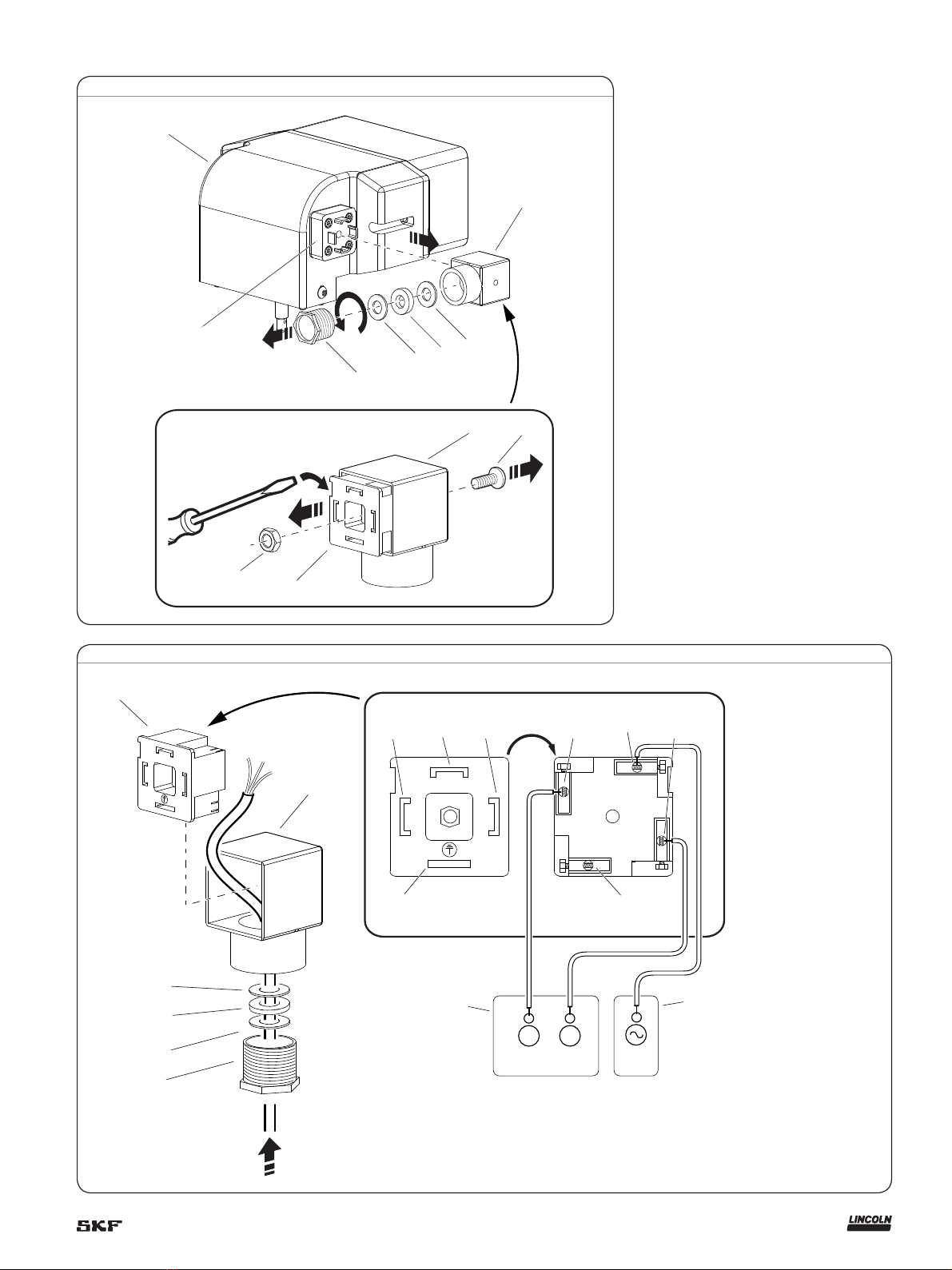

Installation ..................... 4

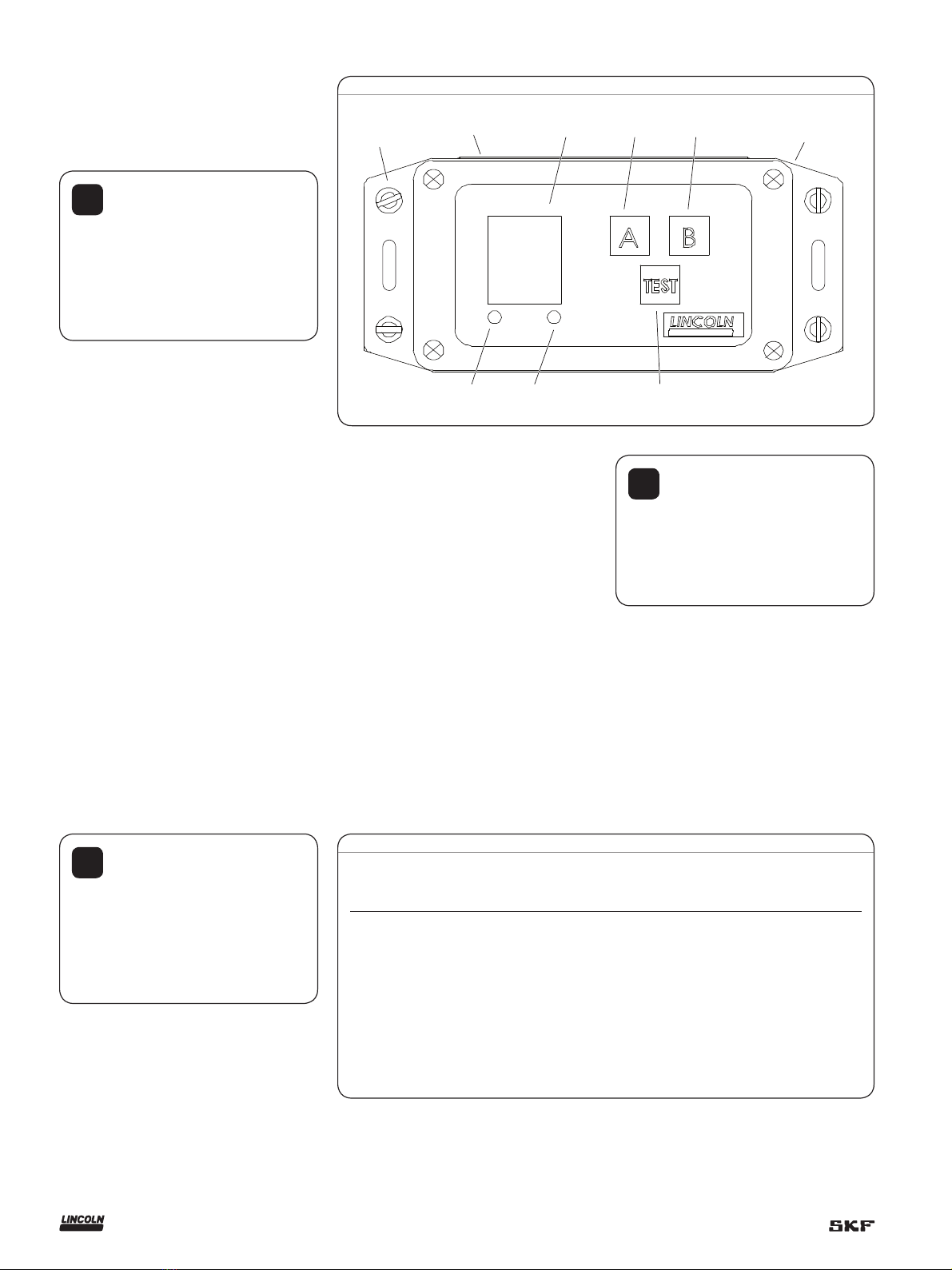

Operation ...................... 6

First use setup ................. 6

Setting cycles per minute ........ 6

Run mode .................... 6

Overrun mode ................. 7

Sleep mode ................... 7

Error codes ................... 7

Replace 9 V battery ............. 8

Solenoid replacement

(error code OC) ................ 8

Electronic overrun controller

operation summary .............. 9

Test controller function ........... 9

Lincoln industrial standard warranty 12

Explanation of signal

words for safety

• Do not install or operate controller until

all instructions within this guide are

completely understood.

• Equipment must only be installed,

maintained, and repaired by persons

familiar with these instructions.

• Do not misuse, over-pressurize, modify

parts, use incompatible chemicals or

fluids, or operate with worn and/or

damaged parts.

• Do not exceed the stated maximum

working pressure of the pump or of the

lowest rated component in your system.

• Always read and follow the fluid

manufacturer’s recommendations

regarding fluid compatibility, and the use

of protective clothing and equipment.

• Failure to comply may result in personal

injury and/or damage to equipment. Wear

adequate personal protection each time

the assembly is used or repaired.

• Do not allow oil to contact skin or eyes.

Safety

Read and carefully observe these

instructions before installing, operating or

troubleshooting this equipment.

Indicates a hazardous situation which,

if not avoided, could result in minor or

moderate injury.

CAUTION

Indicates a hazardous situation which,

if not avoided will result in death or

serious injury.

WARNING

Indicates a hazardous situation which,

if not avoided, will result in death or

serious injury.

DANGER

Indicates a hazardous situation which,

if not avoided, will result in death or

serious injury.

SAFETY INSTRUCTIONS

This is the safety alert symbol. It is used

to alert you to potential physical injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

!Notice

Failure to comply with any danger,

warning, caution, or notice, as well as

any unintended or misuse, will result in

loss of claim for warranty or liability for

this equipment.

2