5

Table of contents

Original EC Declaration of Incorporation in accordance with

Directive 2006/42/EC, Appendix II Part 1 B..................... 2

Original UK Declaration of incorporation according to the Supply

of Machinery (Safety) Regulations 2008 No. 1597 Annex

II .............................................................................................. 2

Masthead.............................................................................................4

Table of contents ...............................................................................5

Safety alerts, visual presentation, and layout................................ 7

1. Safety instructions ........................................................................8

1.1 General safety instructions ....................................................8

1.2 General electrical safety instructions ...................................8

1.3 General behaviour when handling the product...................8

1.4 Intended use ............................................................................8

1.5 Persons authorized to use the product................................8

1.6 Foreseeable misuse ................................................................9

1.7 Referenced documents...........................................................9

1.8 Prohibition of certain activities..............................................9

1.9 Painting plastic components and seals ................................9

1.10 Safety markings on the product .........................................9

1.11 Note on the type plate..........................................................9

1.12 Notes on CE marking ...........................................................9

1.13 Note on Low Voltage Directive ........................................ 10

1.14 Note on UKCA marking ..................................................... 10

1.15 Note on EAC marking........................................................ 10

1.16 Note on China RoHS mark ............................................... 10

1.17 Emergency shutdown........................................................ 10

1.18 Assembly, maintenance, fault, repair.............................. 10

1.19 First start-up, daily start-up ............................................ 10

1.20 Residual risks...................................................................... 11

2. Lubricants.....................................................................................12

2.1 General information............................................................. 12

2.2 Material compatibility .......................................................... 12

2.3 Temperature characteristics............................................... 12

2.4 Ageing of lubricants ............................................................. 12

2.5 Avoidance of malfunctions and hazards ........................... 12

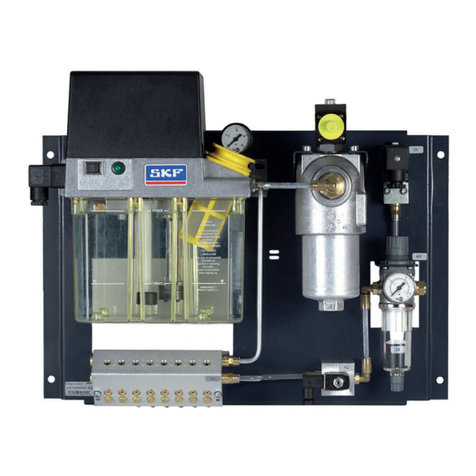

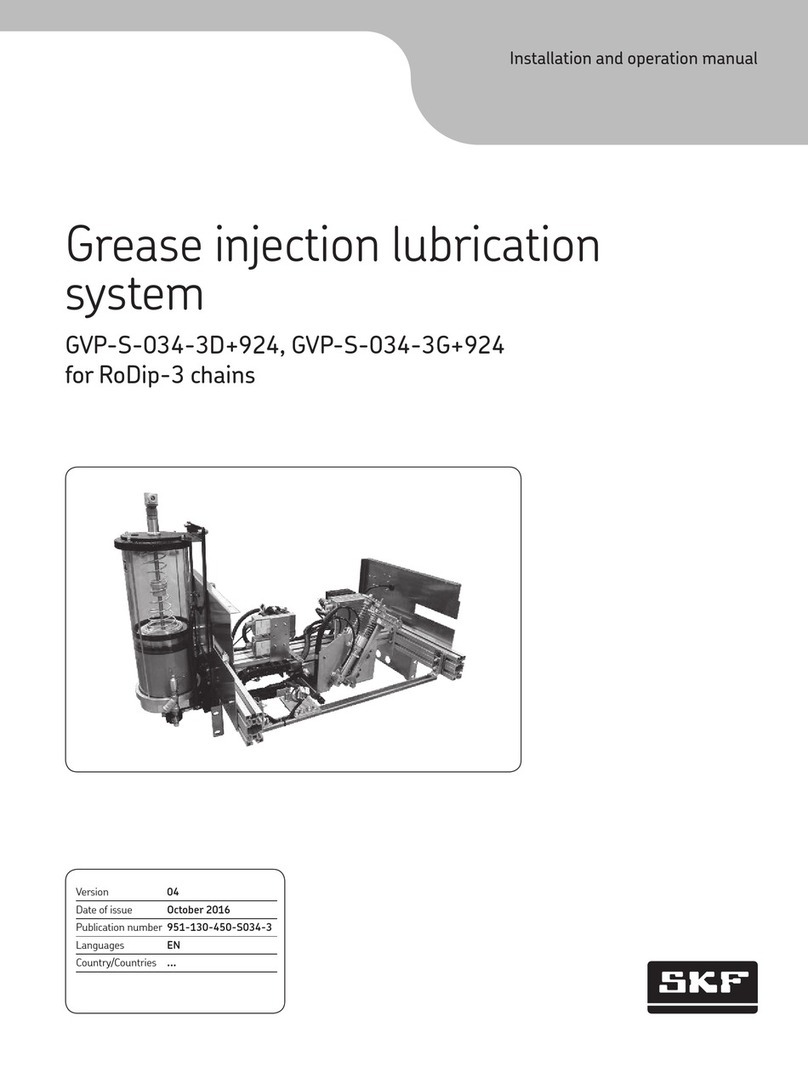

3. Overview, functional description ...............................................13

3.1 Overview................................................................................ 13

3.2 General .................................................................................. 14

3.3 How Oil+Air lubrication works ............................................ 14

3.4 Fields of application ............................................................. 14

3.5 Design.................................................................................... 14

3.6 Functional description ......................................................... 15

3.6.1 Hydraulic diagram of an Oil+Air lubrication unit.. 16

3.7 Description of components ................................................. 17

3.7.1 Gear pump unit......................................................... 17

3.7.2 Compressed air regulating valve............................ 17

3.7.3 Pressure switch for minimum air pressure.......... 18

3.7.4 Oil+Air mixing valve with metering........................ 18

4. Technical data..............................................................................20

4.1 Type identification code....................................................... 22

5. Delivery, returns, storage...........................................................24

5.1 Delivery.................................................................................. 24

5.2 Return shipment .................................................................. 24

5.3 Storage .................................................................................. 24

5.4 Storage temperature range................................................ 24

5.5 Storage conditions for products filled with lubricant ...... 24

5.5.1 Storage period up to 6 months.............................. 24

5.5.2 Storage period between 6 and 18 months .......... 24

5.5.3 Storage period more than 18 months .................. 24

6. Assembly.......................................................................................25

6.1 General .................................................................................. 25

6.2 Setup and attachment......................................................... 25

6.3 Assembly drawing with minimum mounting dimensions26

6.3.1 Minimum mounting dimensions ............................ 26

6.3.2 Attachment of an Oil+Air lubrication unit ............. 27

6.4 Electrical connection ............................................................ 28

6.4.1 Electric motor connection ....................................... 28

6.4.2 Oil dirt indicator switch............................................ 29

6.4.3 Pressure switch for minimum air pressure (DL) . 29

6.4.4 3/2 directional control valve for switching

compressed air on and off................................................. 30

6.4.5 Inductive loads .......................................................... 30

6.5 Control and monitoring ....................................................... 30

6.5.1 Oil+Air lubrication unit without control unit ......... 30

6.5.2 Terminal diagram 230/115 VAC without control

unit........................................................................................ 31

6.5.3 Terminal diagram 24 VDC without control unit .. 32

6.5.4 Oil+Air lubrication unit with control unit............... 33

6.5.5 Terminal diagram 230/115 VAC with control unit

.............................................................................................. 34

6.5.6 Terminal diagram 24 VDC with control unit ........ 35

6.6 Air supply line connection ................................................... 36

6.7 Lubrication line connection................................................. 37

6.8 Bleeding the Oil+Air mixing valve MV20x......................... 38

6.8.1 Bleeding the main oil channel ................................ 38

6.8.2 Bleeding the oil outlets............................................ 39

6.8.3 Bleeding the metering mechanisms...................... 40

6.9 General information on lubrication line routing............... 40

7. First start-up................................................................................41

7.1.1 Setting up.................................................................. 42

8. Operation......................................................................................43

8.1 General .................................................................................. 43

8.1.1 Oils permitted ........................................................... 43

8.2 Feed of lubricant to the bearing......................................... 43

8.3 Setting the lubricant flow rate............................................ 44

8.4 Adjusting the air flow rate................................................... 46

8.4.1 Air flow rate in Nl/min ............................................. 47

8.5 Changing metering on MV20x-1.. ..................................... 48

8.6 General notes........................................................................ 48

9. Maintenance and repair .............................................................50

9.1 General .................................................................................. 50

9.2 Maintenance and repair ...................................................... 50

9.3 Cleaning the compressed air filter ..................................... 51

9.4 Cleaning the oil filter............................................................ 51

10. Cleaning......................................................................................52

10.1 Basics................................................................................... 52

10.2 Interior cleaning................................................................. 52

10.3 Exterior cleaning ................................................................ 52

11. Faults, causes, and remedies ..................................................53

11.1 General................................................................................ 53

11.2 Malfunctions and their resolution.................................... 53

12. Repairs........................................................................................55

13. Shutdown, disposal...................................................................55