Technical Istructions Telemag THG/ TLG

531e1655_0701 page 5/8

Any subsequent fastening bores in the aluminium tubes may only be made by

SKF.

The sides of the tubes must not be scratched, otherwise the tube guide will be

damaged. This can result in malfunctions.

3.3 Electrical connection

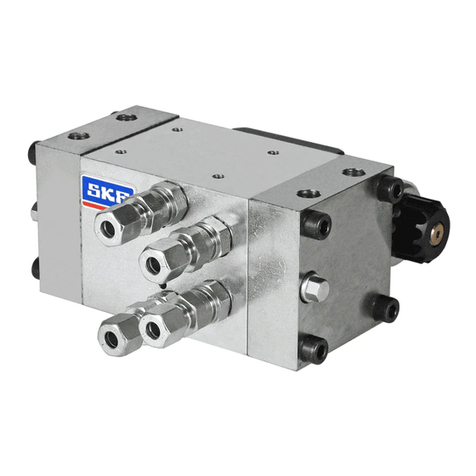

Fig. 2 – Connection

The supply voltage and control unit are connected via the jack plug to a SKF

cont r ol uni t or a master actuator.

Connected load: 24 V DC, 6 A; see type plate

The power cable, when plugged into the socket, is strain-relieved and sealed. The

jack plug has a bayonet lock which must be fitted correctly into the connection

socket and locked in position. To lock the jack plug, use SKF Special Key

No. 140375.

Fig. 3 – Plugging in the control cable

3.4 Start up

The Telemag is ready for operation once all mechanical and electrical installation

work has been completed correctly. The actuator is switched using the

handswitch or footswitch connected to the control unit, depending on the de-

sign.

Motor Laufrichtung

Motor direction

During installation, ensure that no ob-

jects or parts of the body are trapped be-

tween the mounting plate of the internal

tube and the outer tube during retrac-

tion. If necessary, a mechanical protec-

tion device should be installed, depend-

ing on where the device is being used.

Danger of crushing!

The power cable must be also be strain-

relieved on the object on which the actu-

ator is installed.

All cables must be secured so that no

forces act on the plugs.

Plugs which are poorly aligned may al-

low liquids to penetrate which can dam-

age the actuator.

The sealing rings of the connecting plug

must be checked for damage each time

they are connected, and should be

greased lightly with Klübersynth VR 69-

252, order no. 521023, to make installa-

tion easier.

Damaged seals must be exchanged. The

use of other gliding agents can lead to

the plastic being damaged.

Electric cables should not be exposed to

the risk of pinching, or to bending or

tensile loads.

Direct connection to a voltage supply is

not permitted, since this can cause dam-

age to the actuator.

The jack plug must be plugged right into

the opening and be locked in position

with the bayonet lock.

IImmppoorrttaanntt!!RRiisskkooffppeerrssoonnaalliinnjjuurryy!!

When the actuator is being actuated, en-

sure that physical objects or parts of the

body cannot become trapped.

If necessary, a mechanical protection de-

vice should be installed, depending on

where the device is being used.

THG TLG

Screw 4 x M6x25 4 x M10x30

Screw-in depth min. 22 mm min. 25 mm

Strength class 10.9 10.9

Tightening torque 9 Nm 40 Nm