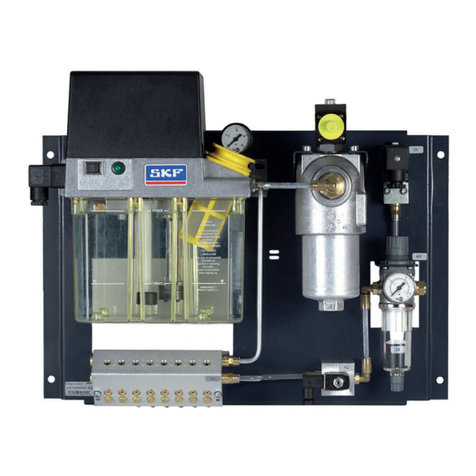

Pump units of the KFG, KFGS and KFGC (CAN bus) series for vehicle lubrication

51-3035-EN

Functional description of progressive

system with KFG pump unit

A general progressive feeder system con-•

sists of the following components: Pump

unit with pump element and pressure

regulating valve

Lubricant lines•

Progressive feeders•

When the pump motor is turned on, the pi-

ston pump delivers lubricant from the lubri-

cant reservoir to the lubricant outlet. The

pump element attached to the outlet delivers

the lubricant further, into the downstream

main line. The lubricant flows through the

main line to the progressive feeder. There, the

lubricant is distributed according to the volu-

me required by the lubrication point being

supplied. In progressive systems with a master

feeder and secondary feeder, the lubricant co-

ming from the pump unit is delivered to the

master feeder. The master feeder distri-

butes the lubricant to the secondary feeders

according to their individual volume require-

ments. From there, the lubricant flows to the

lubrication points.

Example of progressive system with KFG pump unit

3

2

7

6 6

5

4

4

4

1

Progressive system with KFG pump unit

1 KFG unit

2 Electrical pump connection

3 Pump element with

pressure regulating valve

4 Lubricant line

5 Master feeder

6 Secondary feeder

7 Lubrication points

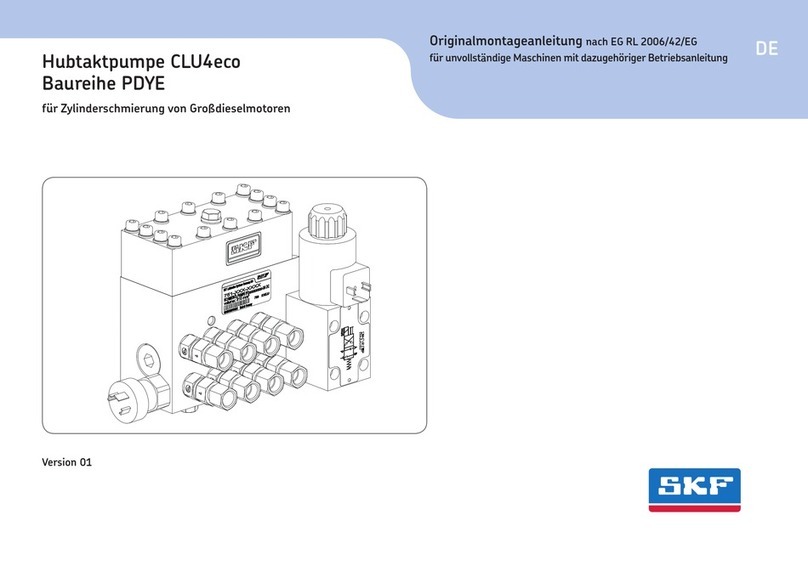

Functional description of progressive

system with KFGS pump unit

The general functional description for progres-

sive systems with a KFG pump unit also ap-

plies for the design with KFGS pump control.

The control unit integrated into the pump

housing allows the following additional con-

figuration, monitoring and connectivity op-

tions:

Interval time and contact time can be•

adjusted independently, including on moni-

tored systems

Recording of remaining intervals and•

remaining lubrication times

Data backup in case of voltage failure•

Non-volatile memory with PIN code•

protection

Connectivity for inductive piston detector•

to monitor the feeder functionConnectivity

for external pushbutton Internal fill level

monitoring (W1 control); lubrication cycle

is halted and a fault signal is sent if the fill

level falls below minimum

KFGS progressive system with piston detector

1 KFGS unit

2 Power supply

3 Fault indicator light

4 Pump element with

pressure regulating valve

5 Lubricant line

6 Master feeder

7 Piston detector

8 Secondary feeder

9 Lubrication points

Example of progressive system with KFGS pump unit

2

3

4

7

9

8 8

6

5

5

5

1

Functional description of progressive

system with KFGC (CAN bus)

pump unit

The general functional description for pro-

gressive systems with a KFGS pump unit also

applies for the design with CAN bus pump

control. The integrated LC-CAN5000 control

unit permits the lubrication zone of a pro-

gressive feeder system to be distributed into

individual lubrication zones for which individ-

ual parameters (e.g. contact and interval

times) can be set. Up to four lubrication sec-

tions can be installed in total. To distribute the

lubricant, a corresponding number of electric

switch valves is installed in the lubricant line

leading from the pump element. A valve is

opened as soon as the control unit starts a

pump cycle period for the corresponding lu-

brication segment. The pump can only pro-

vide one lubrication segment with adequate

lubrication, so it must be ensured that only

one valve is opened during operation. This is

handled by the internal control unit in auto-

matic and semiautomatic operation.

A 5/4 directional solenoid valve can optionally

be used in place of single valves.

Progressive system with KFGC (CAN bus) pump unit