2SKF LAGD 400

EC Declaration of conformity ....................................................................................3

Safety recommendations ..........................................................................................4

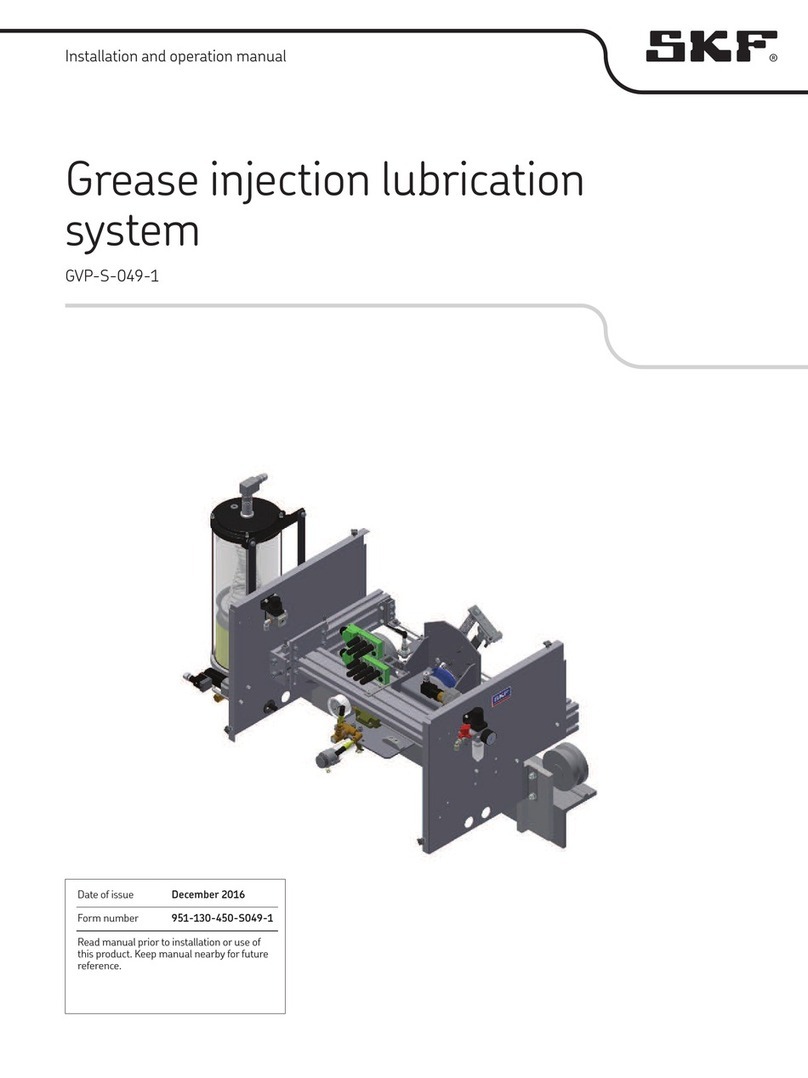

1. Application .......................................................................................................5

2. Description .......................................................................................................5

2.1 Identification of parts .................................................................................................... 5

2.2 Method of operation ...................................................................................................... 5

2.3 Grease supply ................................................................................................................. 5

2.4 Lubrication tubes ........................................................................................................... 6

2.5 Contents .......................................................................................................................... 6

3. Technical data ..................................................................................................7

4. Installation instructions ....................................................................................8

4.1 Mounting ......................................................................................................................... 8

4.2 Electrical connections .................................................................................................... 8

4.3 Fitting the SKF grease cartridge ................................................................................. 9

4.4 Connection of lubrication tubes to the lubricator ..................................................... 9

4.5 Pre-filling of lubrication tubes ...................................................................................10

4.5.1 Manual pre-filling ...........................................................................................10

4.5.2 Automatic pre-filling ......................................................................................10

4.6 Connection of tubes to the application .....................................................................10

4.7 LAPN connection nipples ...........................................................................................11

5. Operation of the lubricator .............................................................................11

5.1 How to switch the lubricator on ................................................................................11

5.2 Adjustment of dispense range ...................................................................................11

5.3 Distance mode .............................................................................................................12

5.4 Volume mode ...............................................................................................................12

5.5 Manual pumping ..........................................................................................................12

5.6 Start-up test ................................................................................................................12

5.7 Counter ..........................................................................................................................12

5.8 Display of metric and imperial units .........................................................................12

5.9 Alarms ...........................................................................................................................13

5.10 External alarms ............................................................................................................13

6. Grease refilling ...............................................................................................13

6.1 Exchange of the grease cartridge .............................................................................13

6.2 How to fill the lubricator with loose grease .............................................................13

7. Selection of SKF greases ...............................................................................14

7.1 Basic grease selection .................................................................................................14

7.2 Special bearing greases ..............................................................................................15

8. Maintenance ..................................................................................................15

8.1 Spare parts ...................................................................................................................16

9. Trouble shooting ............................................................................................17

Table of contents

Original instructions