SKF MityVac MV7201 Instruction Manual

User and maintenance instructions

Model MV7201

Fluid evacuator plus

Date of issue November 2017

Form number 801672

Version 2

DANGER

Do not use with gasoline, diesel,

kerosene or 2 stroke mixture.

Failure to comply may result in death

or serious injury.

Safety

Read and carefully observe operating

instructions before unpacking and operating

pump. Pump must be operated, maintained

and repaired exclusively by persons familiar

with operating instructions. Local safety

regulations regarding installation, operation

and maintenance must be followed.

Operate pump only after safety

instructions and this service manual are

fully understood.

Explanation of signal

words for safety

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Explanation of signal words for safety . . 2

Precaution . . . . . . . . . . . . . . . . . . . . . . . 3

Automatic shut-off valve . . . . . . . . . . . . 3

Reservoir specifications . . . . . . . . . . . . . 3

Extract from and dispense

motor oil into crankcase. . . . . . . . . . . . 3

Extract from and dispense

fluid into transmission cases

and differentials . . . . . . . . . . . . . . . . . . 4

Extract and dispense

coolant into cooling system . . . . . . . . . 5

Extract brake fluid from

master cylinder . . . . . . . . . . . . . . . . . . . 5

Technical questions. . . . . . . . . . . . . . . . . 5

Service parts. . . . . . . . . . . . . . . . . . . . . . 5

Illustrated parts break down. . . . . . . . . . 6

Model MV7201 service parts list . . . . . . 6

NOTE

Emphasizes useful hints and

recommendations as well as

information for efficient and trouble-

free operation.

CAUTION

Indicates a dangerous situation that can lead

to light personal injury or property damage if

precautionary measures are ignored.

WARNING

Indicates a dangerous situation that can lead

to death or serious injury if precautionary

measures are ignored.

DANGER

Indicates a dangerous situation that will lead

to death or serious injury if precautionary

measures are ignored.

2

Precaution

Equipment is designed for servicing a variety

of vehicles in a safe and convenient manner;

however, differences in engine blocks and

dip stick configurations make it impossible to

use equipment on every vehicle.

Documented procedures are to serve as

guidelines for general use of equipment. In

addition to guidelines, always follow

manufacturer’s recommended procedures

when attempting to use equipment on each

unique vehicle.

Do not attempt to force tubes included

with equipment into dip stick tube that does

not readily accept smaller of two tubes.

Tubes that appear to be too large are not

designed to be used with these particular

vehicles.

Draining oil with evacuator unit through

dipstick tube is expected to be simple and

straightforward. Instructions are written as a

general guideline only. Always read carefully

and understand instructions prior to

using equipment.

Tighten lid-to-reservoir screws before

first use, and periodically after, to ensure

proper seal.

Automatic shut-off valve

Reservoir tank of fluid evacuator plus is

equipped with automatic shut-off valve to

prevent over-filling of reservoir tank. As fluid

flows into reservoir tank, float raises. When

float reaches shut-off valve, flow of fluid

being extracted automatically stops.

While automatic shut-off is in place it is

not guaranteed to prevent overfill. Make sure

the extractor is on a level surface and take

caution to not overfill the unit.

WARNING

Do not adjust pressure relief valve.

Build pressure by pumping at pumping rate

of maximum 40 strokes per minute. Unit

should not be pressurized by any other

means.

Failure to comply may result in death or

serious injury

NOTE

Do not force tube into crankcase. Stop

inserting tube in if any force is recognized.

Dealer should be contacted for detail on

using equipment to evacuate oil from vehicle

if issues arise.

Extract from and

dispense motor oil

into crankcase

1 Park vehicle on level ground.

2 Ensure transmission of vehicle is in

neutral or park and apply parking brake.

3 Start engine.

4 Allow engine to idle until it reaches

normal operating temperature. Once

this is accomplished, turn engine off.

NOTE

It may be necessary to empty fluid reservoir

tank and restart process if crankcase capacity

exceeds 8 liters (2.11 gallons).

Table 1

Reservoir specifications

Capacity 2.3 gallons (8,8 liters)

Maximum operating

temperature

175 °F (80 °C)

Recommended fluids Engine oil, gear and

transmission oils,

power steering fluid,

coolants, brake fluid,

and other similar fluids

NOTE

Verify tube is in connector all the way to

prevent leakage.

5 Remove engine oil dipstick.

6 Select and insert smallest diameter

dipstick tube into dipstick hole until it

reaches bottom of oil pan.

7 Connect main suction tube to

dipstick tube.

8 Insert opposite end of main suction tube

into 10mm x 90° tube connector on top

of reservoir tank.

NOTE

Do not extract oil when temperature is above

176 °F (80 °C).

9 Place selector valve mounted on side of

pump assembly to evacuate.

10 Raise pump handle on reservoir tank

until highest limit is reached.

11 Pump handle approximately ten times.

Unit will begin to extract oil from engine

crankcase.

3

12 Once oil is extracted from crankcase,

remove expandable rubber plug from

reservoir tank.

13 Pour oil from tank into suitable

container, and dispose of oil in

appropriate manner.

14 Rinse out reservoir tank with clean

solvent or engine degreaser. Allow to dry

thoroughly.

15 If using fluid evacuator plus to dispense

oil, fill cleaned reservoir tank with new oil

and switch selector valve mounted on

side of pump assembly to dispense.

16 Pull up on pump handle and begin

pumping until engine crankcase is filled

to desired level.

17 Run engine momentarily to circulate

new oil and then re-check level.

4 Connect main suction tube to

dipstick tube.

5 Insert opposite end of main

suction tube into 10mm x 90° tube

connector on top of reservoir tank.

WARNING

In some applications this may require jacking

or lifting vehicle. Use appropriate safety

stands to avoid serious or fatal injury.

6 Place selector valve mounted on side of

pump assembly to evacuate.

7 Raise pump handle on reservoir tank

until highest limit is reached. Pump

handle approximately ten times. Unit will

begin to extract transmission fluid from

transmission.

8 Once transmission fluid has been

extracted, remove expandable

rubber plug from reservoir tank.

9 Pour transmission fluid from tank into

suitable container, and dispose of

transmission fluid in an

appropriate manner.

10 Rinse out reservoir tank with clean

solvent or engine degreaser. Allow to dry

thoroughly.

11 If using fluid evacuator plus to dispense

transmission fluid, fill cleaned reservoir

tank with new transmission fluid and

simply switch selector valve mounted on

the side of pump assembly to dispense.

12 Pull up on pump handle and continue

pumping until the transmission is filled

to the desired level.

13 Follow operating instructions for vehicle

to properly check transmission fluid level.

Extract from and

dispense fluid into

transmission cases

and differentials

1 Follow steps 1 and 2 above in Extract and

dispense motor oil into a crankcase.

2 Remove transmission fluid dipstick or

fill plug.

3 Select and insert appropriate

diameter dipstick tube into dipstick fill

hole until it reaches bottom of

transmission pan or gear case.

NOTE

Verify tube is in connector all the way to

prevent leakage.

4

Extract brake fluid

from master cylinder

1 Clean exterior of master cylinder and

master cylinder cap.This will prevent dirt

from entering master cylinder reservoir

when cap is removed.

2 Remove lid of master cylinder reservoir.

3 Select appropriate dipstick tube and

connect it to main suction tube.

WARNING

Never remove cap from radiator or expansion

tank while engine is at operating

temperature. Always allow engine to cool

before removing radiator cap or expansion

tank cap. Cooling system is under pressure.

Failure to allow engine to cool before

attempting to remove cap could result in

death or serious injury. WARNING

Prior to inserting extraction tube into master

cylinder reservoir, be sure extraction tube is

clean and free of any other types of fluid.

Failure to do so would result in

contamination of brake fluid in hydraulic

system and cause potential brake failure.

Extract and dispense

coolant into cooling

system

1 Allow engine to cool.

2 Remove radiator/expansion tank cap.

3 Select largest diameter dipstick tube and

insert tube into radiator neck or

expansion tank.

4 Insert opposite end of main suction tube

into 10 mm x 90° tube connector on top

of reservoir tank.

4 Insert opposite end of main suction tube

into 10mm x 90° tube connector on top

of reservoir tank.

Technical questions

If you have questions, or require technical

service, please contact trained service

technicians at: 1-314-679-4200 ext. 4782.

Visit website www.mityvac.com for new

products, catalogs and instructions for

product use.

Service parts

To order replacement or service parts, visit

www.mityvacparts.com or call toll free

1-800-992-9898.

NOTE

Verify tube is in connector all the way to

prevent leakage.

5 Place selector valve mounted on side of

pump assembly to evacuate.

6 Raise pump handle on reservoir tank

until highest limit is reached. Pump

handle approximately ten times. Unit will

begin to extract coolant from

cooling system.

7 Once coolant has been extracted,

remove expandable rubber plug from

reservoir tank.

8 Pour coolant from tank into suitable

container, and dispose of it in

appropriate manner.

9 Rinse out reservoir tank with clean

solvent or engine degreaser. Allow to dry

thoroughly.

10 If using fluid evacuator plus, fill cleaned

reservoir tank with new coolant and

switch selector valve mounted on side of

pump assembly to dispense.

11 Pull up on pump handle and continue

pumping until cooling system is filled to

desired level.

12 Be sure to run engine until it reaches

operating temperature to circulate new

coolant and then re-check level to verify

it is full.

NOTE

Verify tube is in connector all the way to

prevent leakage.

5 Place selector valve mounted on side of

pump assembly to evacuate.

6 Insert end of extraction tube into master

cylinder reservoir.

7 Raise pump handle on reservoir tank

until highest limit is reached.

8 Pump handle approximately ten times.

Unit will begin to extract brake fluid from

master cylinder reservoir.

9 Once break fluid has been extracted,

remove expandable rubber plug from

reservoir tank.

10 Pour break fluid from tank into suitable

container and dispose of it in

appropriate manner.

11 Rinse out reservoir tank with clean

solvent or engine degreaser. Allow to

dry thoroughly.

12 After all repairs are accomplished, refill

system with new, manufacturer approved

brake fluid from sealed container.

5

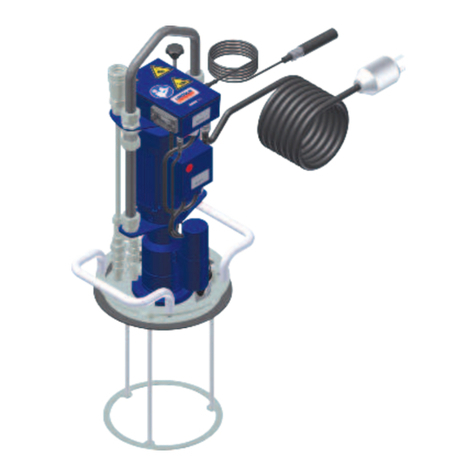

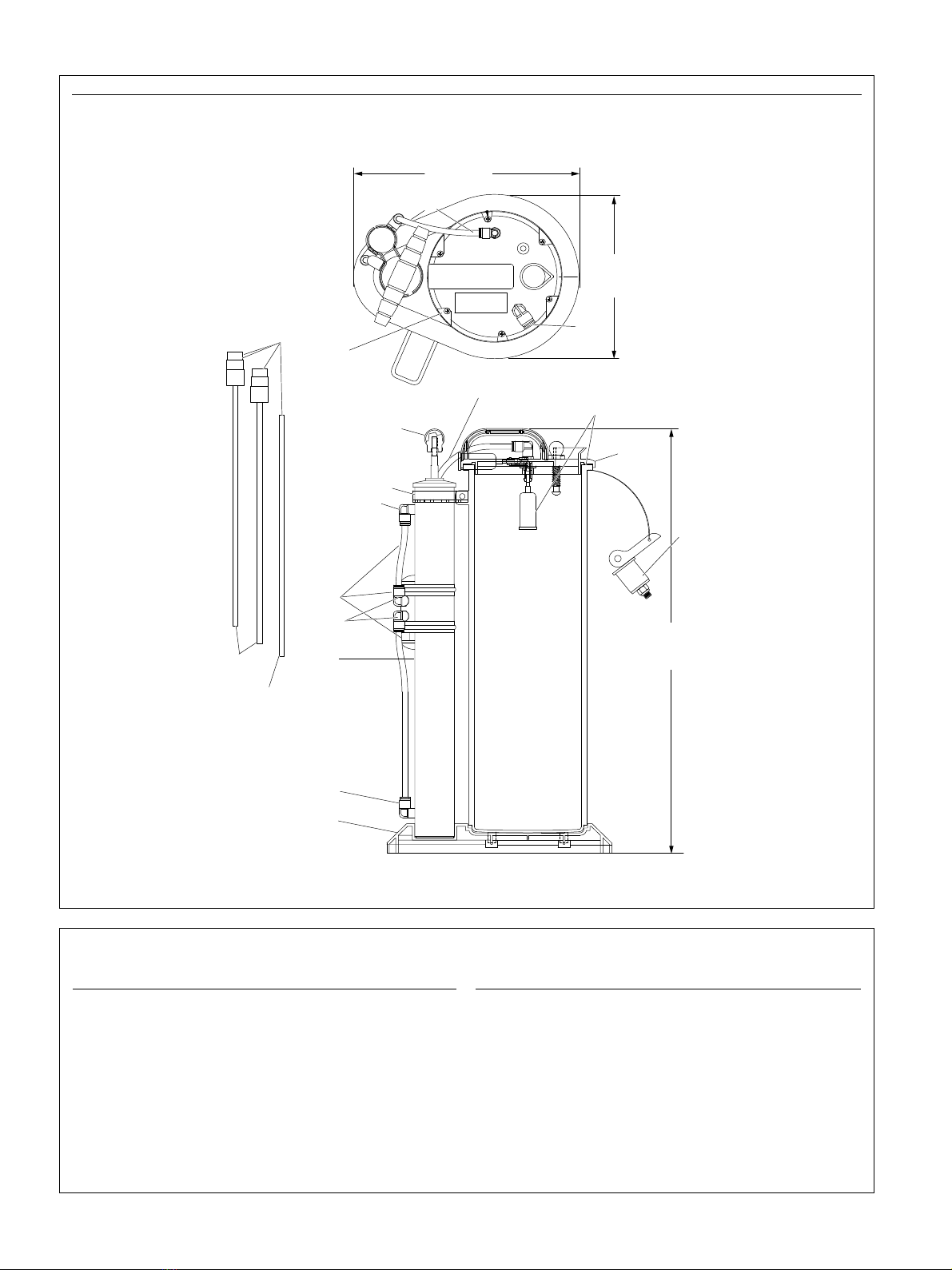

4

10

10

12

9

7

2

8

1

4

4

5

11

3

3

13

4

12

9.25 in

(125, 7 mm)

12.38 in

(314,4 mm)

6

23.92 in

(607,5 mm)

1)

2)

Model MV7201 service parts list

Item Description Part no. Item Description Part no.

1Vacuum tube kit 822559 7 Evacuator top kit 5) 822576

2Handle kit 822561 8 Pump strap kit 822578

3Valve kit 1) 822563 9 Expandable plug kit 822593

4Tube connector kit 2) 822566 10 Top seal kit 822821

5Pump assembly kit 3) 822572 11 Tube connector with check kit 822998

6Base kit 4) 822574 12 Field service kit 6) MVM9000

13 Replacement tube 801671

1) Consists of three tubes, three 8 mm connectors and valve.

2) Consists of three 8 mm connectors and three 10 mm connectors.

3) Consists of two 8 mm connectors, two tubes and pump assembly.

4) Consists of base and foot bracket.

5) Consists of top and overfill float.

6) Consists of top seal, six locknuts, 10 mm connector, and six M5 screws.

1) Dipstick tubes.

2) Main suction tube.

Fig. IPB 1

6

This page left intentionally blank.

7

skf.com | mityvac.com

® SKF and MityVac are registered trademarks of the SKF Group.

© SKF Group 2017

The contents of this publication are the copyright of the publisher and may not be reproduced (even

extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy

of the information contained in this publication but no liability can be accepted for any loss or damage

whether direct, indirect or consequential arising out of the use of the information contained herein.

November 2017 · Form 801672 Version 2

Table of contents

Other SKF Water Pump manuals

SKF

SKF RA User manual

SKF

SKF PAB Series User manual

SKF

SKF LINCOLN FlowMaster II A Series User manual

SKF

SKF MSU Series User manual

SKF

SKF SKF-MPB-PUMP-1/1 User manual

SKF

SKF 40PGA User manual

SKF

SKF Lincoln HTL 201 User manual

SKF

SKF THAP 030E User manual

SKF

SKF KFGL User manual

SKF

SKF LINCOLN P203 User manual

Popular Water Pump manuals by other brands

Kärcher

Kärcher BP 3 manual

Proeco

Proeco 1051 Assembly instructions

SunSun

SunSun SuperEco JTP Series Operation manual

PSG Dover

PSG Dover WILDEN PRO-FLO P8 Engineering, operation & maintenance

Fristam Pumps

Fristam Pumps FPM Series English translation of the original German Operating Manual

RIDGID

RIDGID RSS-1000 Operating instructions and parts manual