AV-SMU70EN-A

Page 2 of 3

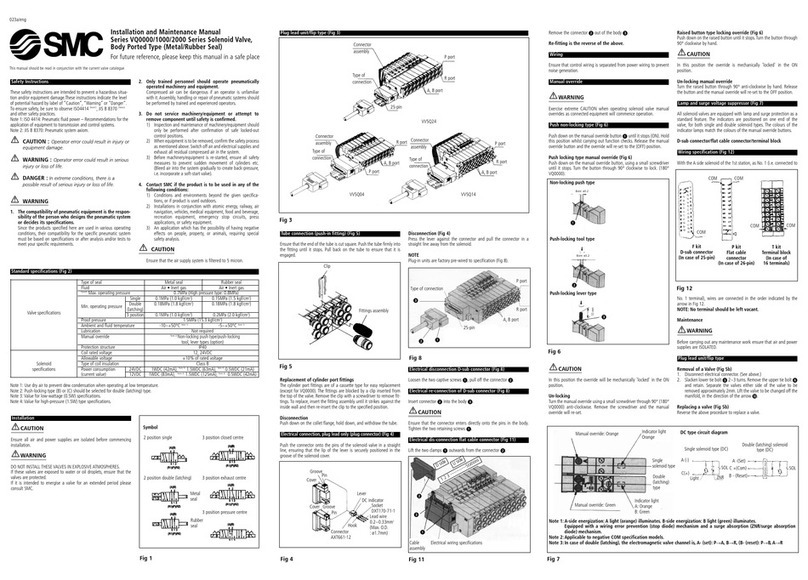

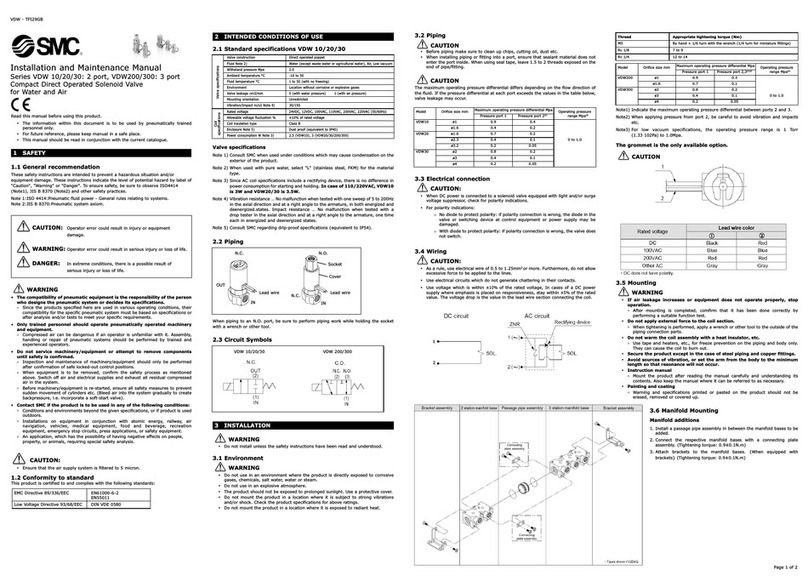

Ground nut

Tightening torque

1.65 to 2.5 N∙m

(Rating symbol)

Refer to the catalogue for DIN

connector part no.

Terminal screw

(3 locations)

Tightening torque

0.2 to 0.25 N∙m

0.2 to 0.25 N∙m

Holding screw

Tightening torque

0.4 N∙m

(Light mounting

location)

3 Installation - continued

regulator. With a standard regulator (AR10 to 60), the outlet side

pressure may not be released when this valve is exhausted.

Operation of solenoid valves on the outlet side

To operate solenoid valves mounted on this product’s outlet side (A port

side), make sure that the outlet side’s pressure (PA) has increased to

the pressure equal to the inlet side (PP).

Operation

The residual pressure release function of this product is for emergency

use only. Avoid using this valve in the same manner as ordinary 3 port

valves.

Using a lubricator

If mounting a lubricator, mount it on the inlet side (P port side) of this

product. If mounted on the outlet side (A port side), back flow of oil will

occur and may spurt out of the valve’s R port.

Operation for air blowing

This product cannot be operated for air blowing due to the mechanism

that switches the main valve to be fully open after the outlet side’s

pressure increases to approximately 1/2 of the inlet side.

Warning

Solenoid valve for 200, 220VAC

The AC solenoid valves with grommet have a built-in rectifier circuit in

the pilot section to operate the DC coil.

With 200V and 220 VAC pilot valves, this built-in rectifier generates

heat when energised. The surface may become hot depending on the

energised condition. To prevent burns, do not touch the solenoid valve.

3.2 Environment Warning

Do not use in an environment where corrosive gases, chemicals, sea

water or steam are present.

Do not use in an explosive atmosphere.

Do not expose to direct sunlight. Use a suitable protective cover.

Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

Do not mount in a location exposed to radiant heat that would result

in temperatures in excess of the product’s specifications

Take suitable protective measures if water, oil or welding spatter is

likely to adhere to the valve.

Take measures to ensure air quality, such as by installing an

aftercooler, air dryer, or water separator. Compressed air that contains

a large amount of drainage can cause a malfunction of pneumatic

equipment such as valves. Therefore, take appropriate measures to

ensure air quality, such as by providing an aftercooler, air dryer, or

water separator.

Take suitable measures to prevent dust or noise if operating in an

environment generating dust or intrusive valve switching noise, by

providing a silencer in the R port.

Caution

Low temperature operation

Although the valve can be operated at temperature as low as 0°C,

measures should be taken to avoid solidifying or freezing drainage and

moisture.

3.3 Piping Caution

Before connecting piping make sure to clean up chips, cutting oil, dust

etc.

When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1.5-2 thread ridges

exposed on the end of the pipe/fitting.

Refer to the instruction manual/operation manual during installation

and make sure to connect to the correct supply port, etc.

F.R.L module combination

When connecting to a modular F.R.L. unit (AC20 to 60), select one of

the spacers, included amongst the accessories. However, modular

combinations with AC40-06 are not possible.

3 Installation - continued

Furthermore, connect soft start-up valves to the outlet side of the F.R.L.

combination.

Inlet side piping conditions

The nominal size of the piping material’s or equipment’s bore should

be equal to or larger than the soft start-up valve’s port size. The

combined sonic conductance of the inlet side’s (P port side’s) piping or

equipment should be equal to or larger than the values below.

Combined sonic conductance

[dm3/(s·bar)]

When the piping is restricted or the supply pressure is insufficient, the

main valve will not switch and air leakage may occur from the R port.

Tighten fittings to the specified tightening torque.

Proper tightening torque (N▪m)

3.4 Lubrication Caution

The valve has been lubricated for life at the factory, and does not

require any further lubrication.

If a lubricant is used in the system, refer to catalogue for details.

Once lubricant is utilized within the system, since the original lubricant

applied within the product during manufacturing will be washed away,

please continue to supply lubrication to the system. Without continued

lubrication, malfunctions could occur. If turbine oil is used, refer to the

corresponding Material Safety Data Sheet (MSDS).

Lubrication amount

If a lubricant is applied excessively, it may accumulate inside the pilot

valve, causing malfunction or delayed response. Avoid using large

amount of lubricant. If it is not avoidable, use an external pilot type,

whereby supply air to the external pilot port contains no oil. This

prevents accumulation of oil inside the pilot valve.

3.5 Wiring Caution

When electric power is connected to a solenoid valve, make sure to

apply correct voltage. Incorrect voltage may cause malfunction or coil

damage.

Check the connections.

Check if the connections are correct after completing all wiring.

External force applied to lead wire

An excessive force to the lead wire may cause wire breakage. Take

appropriate measures to avoid applying a force of 30 N or more to the

lead wire.

Voltage leakage

Particularly when using a C-R element (surge voltage suppressor) to

protect the switching element, take note that leakage current will flow

through the C-R element, increasing leakage voltage.

AC coil is 8% or less of rated voltage.

DC coil is 3% or less of rated voltage.

3.6 Air supply Caution

Install air filters close to the valve on the upstream side.

Implement countermeasures by installing after-cooler or air dryer, or

water separator, etc.

3 Installation - continued

The compressed air containing a large amount of moisture may result in

a malfunction of the valve and other pneumatic equipment. Install an

after-cooler, air dryer or water separator or otherwise take an

appropriate measure.

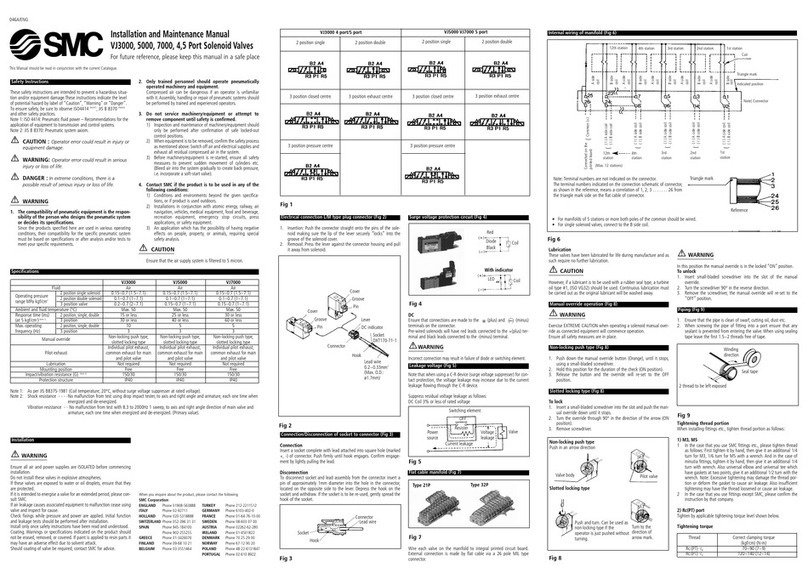

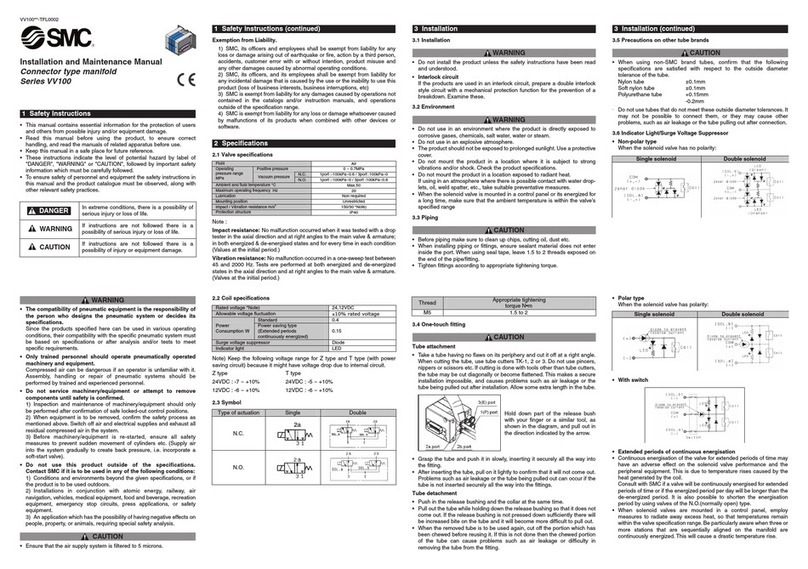

3.7 Surge voltage suppressor Caution

3.7.1 DC power supply

3.7.1.1 Grommet –standard type (with polarity)

With light/surge voltage suppressor (Z)

NOTE1: Connect correctly the lead wires to + (positive) and - (negative)

indications on the connector.

NOTE2: Solenoids, whose lead wires have been pre-wired: positive

side (+) is red and negative side (-) is black.

3.7.1.2 DIN Terminal

With light/surge voltage suppressor (DZ)

DIN terminal has no polarity.

3.7.2 AC power supply

3.7.2.1 Grommet

With light (GZ)

3.7.2.2 DIN Terminal

With light (DZ) and (YZ)

NOTE1: Surge voltage suppressor of varistor has residual voltage

corresponding to the protective element and rated voltage; therefore,

protect the controller side from the surge voltage. The residual voltage

of the diode is approximately 1V.

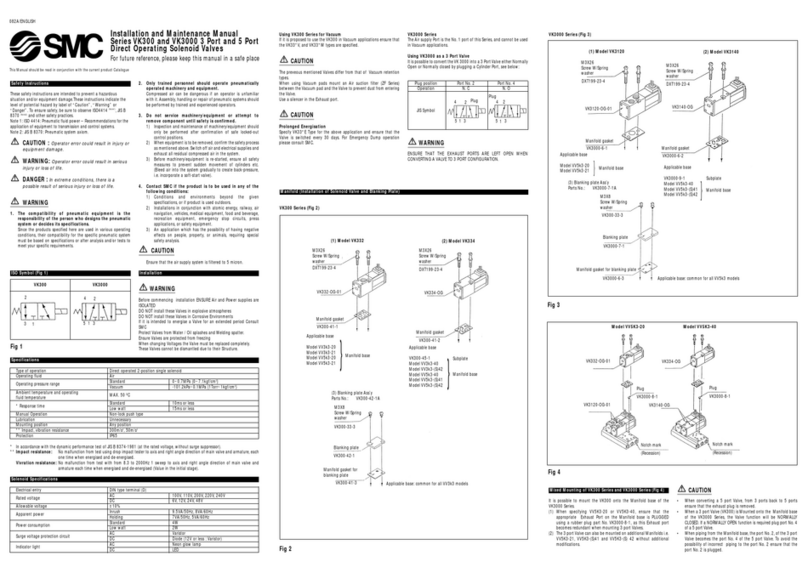

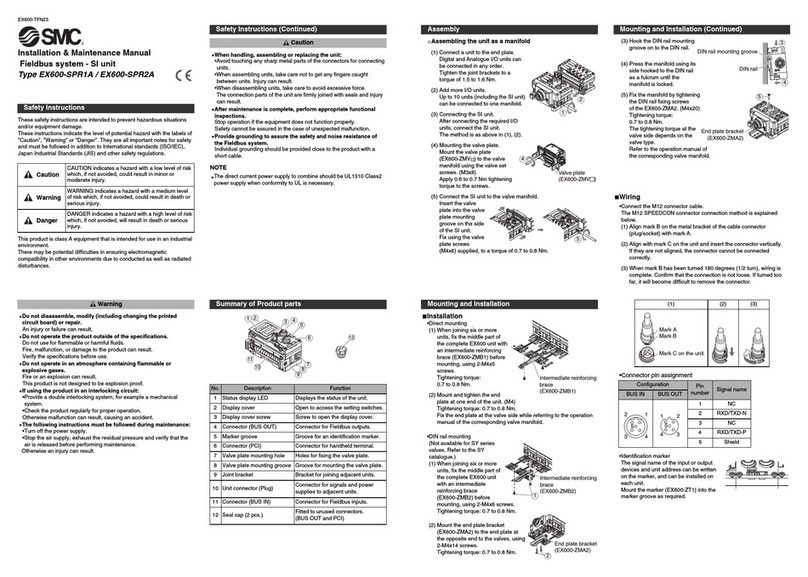

3.8 How to use DIN terminal

3.8.1 Construction

Type “Y”

Y type DIN connector is a DIN connector that confirms to the DIN pitch

8-mm standard.

Type “D”

D type DIN connector with 9.4 mm pitch between terminals is not

interchangeable with Y type connector.

To distinguish between “Y”and “D”type DIN connector, “Y”has “N”

listed at the end of voltage symbol. For connector parts without lights,

“N” is not indicated. Refer to the name plate to distinguish.

“Y” Dimensions are the same as “D”type DIN connector.

When exchanging the pilot valve assembly only, “V115K-□D-X400”

is interchangeable with “V115K-□Y-X400”. Do not replace “V111K-

□G-X400”with “V115-□D/□Y-X400”(DIN terminal), and vice versa.

3.8.2 Connection

1. Loosen the holding screw and pull the connector out of the solenoid

valve terminal block.

3 Installation - continued

2. After removing the holding screw, insert a flat head screwdriver, etc.

into the notch on the bottom of the terminal block and pry it open,

separating the terminal block and the housing.

3. Loosen the screw (slotted screws) on the terminal block. Insert the

lead cores wires into the terminals according to the connection

method, and secure the wires by re-tightening the terminal screw.

4. Secure the cord by tightening the gland nut.

Caution

When making connections, take note that using other than the

supported size (ø3.5 to ø7) heavy duty cord will not meet IP65

(enclosure) standards. Ensure to tighten the gland nut and holding

screw within their specified torque ranges.

3.8.3 Changing the entry direction

After separating the terminal block and housing, the cord entry can be

changed by attaching the housing in the desired direction (4 directions

at 90° intervals).

*When equipped with light, handle carefully to avoid damage to the light

with the lead wires in the cable.

NOTE: Plug in and pull out the connector vertically without tilting to one

side.

3.8.4 Compatible cable

Cable O.D.: ø3.5 to ø7

(Reference) 0.5mm2, 2-core or 3-core, equivalent to JIS C 3306

3.8.5 DIN Connector part numbers

3.8.6 Circuit Diagram with light