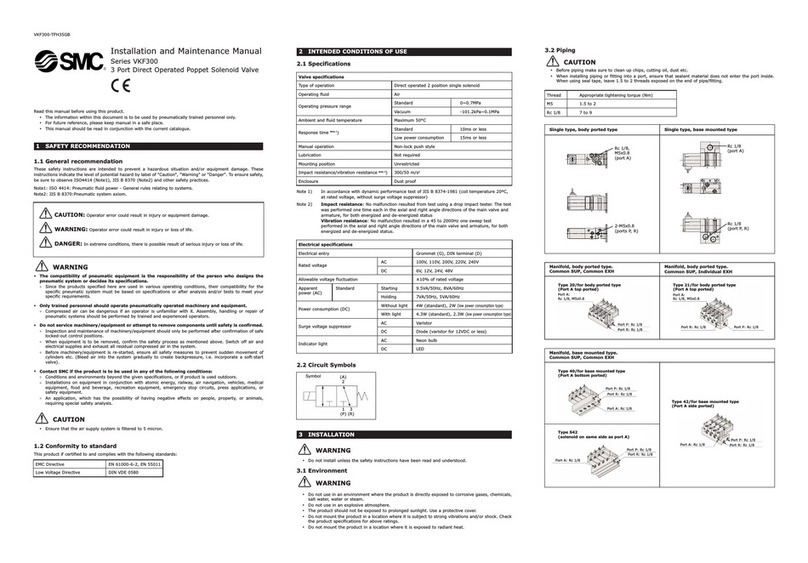

2 INTENDED CONDITIONS OF USE

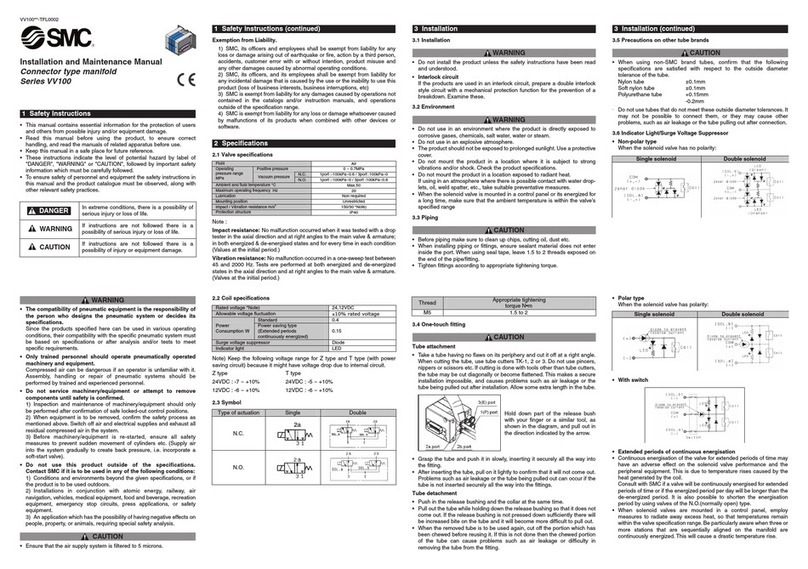

2.1 Specifications

(Note 1) At low temperatures, use dry air with no condensation.

(Note 2) Vibration resistance: Conditions when tested with one sweep of 8.3 to

2000Hz in the axial direction and at a right angle

to the armature, in both energized and

de-energized states

Impact resistance: Conditions when tested with a drop tester in the axial

direction and at a right angle to the armature, one

time each in energized and de-energized states

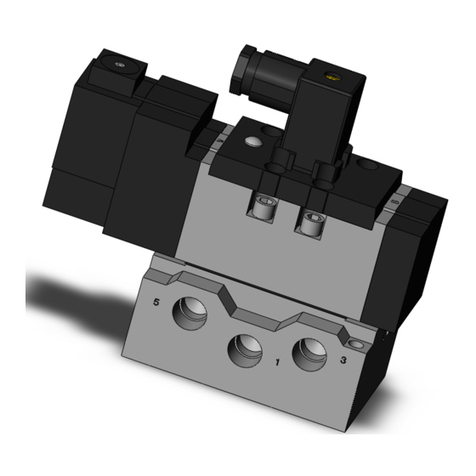

2.2 Piping

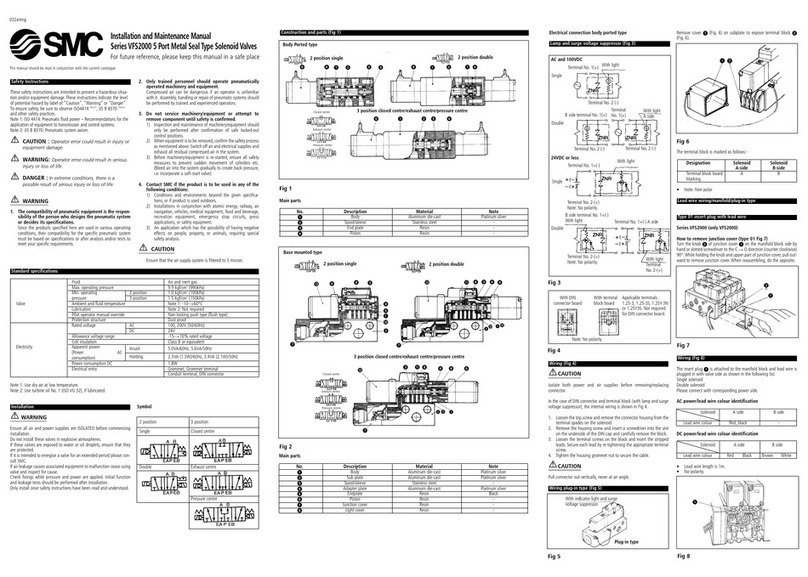

2.3 Circuit Symbols

3 INSTALLATION

WARNING:

Do not install unless the safety instructions have been read and understood.

3.1 Environment

WARNING:

Do not use in an environment where the product is directly exposed to corrosive

gases, chemicals, salt water, water or steam.

Do not use in an explosive atmosphere.

The product should not be exposed to prolonged sunlight. Use a protective cover.

Do not mount the product in a location where it is subject to strong vibrations

and/or shock. Check the product specifications for above ratings.

Do not mount the product in a location where it is exposed to radiant heat.

Read this manual before using this product

The information within this document is to be used by pneumatically trained

personnel only.

For future reference, please keep manual in a safe place.

This manual should be read in conjunction with the current catalogue.

1 SAFETY RECOMMENDATION

1.1 General recommendation

These safety instructions are intended to prevent a hazardous situation and/or

equipment damage. These instructions indicate the level of potential hazard by label of

"Caution", "Warning" or "Danger". To ensure safety, be sure to observe ISO4414 (Note1),

JIS B 8370 (Note2) and other safety practices.

Note 1:ISO 4414:Pneumatic fluid power - General rules relating to systems.

Note 2:JIS B 8370:Pneumatic system axiom.

WARNING:

•The compatibility of pneumatic equipment is the responsibility of the person

who designs the pneumatic system or decides its specifications.

Since the products specified here are used in various operating conditions, their

compatibility for the specific pneumatic system must be based on specifications or

after analysis and/or tests to meet your specific requirements.

•Only trained personnel should operate pneumatically operated machinery

and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it. Assembly,

handling or repair of pneumatic systems should be performed by trained and

experienced operators.

•Do not service machinery/equipment or attempt to remove components until

safety is confirmed.

Inspection and maintenance of machinery/equipment should only be performed

after confirmation of safe locked-out control positions.

When equipment is to be removed, confirm the safety process as mentioned above.

Switch off air and electrical supplies and exhaust all residual compressed air in the

system.

Before machinery/equipment is re-started, ensure all safety measures to prevent

sudden movement of cylinders etc. (Bleed air into the system gradually to create

backpressure, i.e. incorporate a soft-start valve).

•Contact SMC if the product is to be used in any of the following conditions:

Conditions and environments beyond the given specifications, or if product is used

outdoors.

Installations on equipment in conjunction with atomic energy, railway, air

navigation, vehicles, medical equipment, food and beverage, recreation

equipment, emergency stop circuits, press applications, or safety equipment.

An application, which has the possibility of having negative effects on people,

property, or animals, requiring special safety analysis.

CAUTION:

Ensure that the air supply system is filtered to 5 micron.

1.2 Conformity to standard

This product is certified to and complies with the following standards:

3.2 Piping

CAUTION:

Before piping make sure to clean up chips, cutting oil, dust etc.

When installing piping or fitting into a port, ensure that sealant material does not

enter the port inside. When using seal tape, leave 1.5 to 2 threads exposed on the

end of pipe/fitting.

CAUTION:

Tube piping method

(Plug lead/ barb fitting type)

1. Cut the tube to the necessary length at right angles to the axial direction using a

tube cutter TK-1, 2 or 3.

2. Insert the tube up to the barb end. If the tube is only pushed in part way, this can

cause air leakage or cause the tube to come out.

3. When inserting the tube into to the barb fitting, insert parallel to the axial direction

to avoid placing excessive lateral load on the barb fitting.

4. Care should also be taken to avoid placing excessive lateral load on the barb fitting

when removing the tube from the barb fitting. When removing using a cutter, care

should also be taken to avoid scratching the barb fitting.

5. After completing tube piping, avoid excessive loads that could pull, compress or

bend the tube.

3.3 Electrical connection

CAUTION:

When DC power is connected to a solenoid valve equipped with light and/or surge

voltage suppressor, check for polarity indications.

For polarity indications:

No diode to protect polarity: if polarity connection is wrong, the diode in the

valve or switching device at control equipment or power supply may be

damaged.

With diode to protect polarity: if polarity connection is wrong, the valve does

not switch.

Cable safety instructions

Avoid mis-wiring, as this can cause malfunction, damage and fire in the unit.

To prevent noise and surge in signal lines, keep all wiring separate from power

lines and high voltage lines. Otherwise, this can cause a malfunction.

Check wiring insulation, as defective insulation can cause damage to the unit when

excessive voltage or current is applied.

Do not bend or pull cables repeatedly, and do not place heavy objects on them or

allow them to be pinched. This can cause broken

CAUTION:

Surge voltage circulation

Surge voltage generated when the power is cut off can flow to the load device in

non-electrified state through the output circuit etc. In particular in a load device in

electrified state, if a load device with high capacity (power consumption) is connected

so that it shares the supply power, this can cause malfunction of the solenoid valve or

damage to the circuit elements inside the solenoid valve or elements in the output

device. A surge absorbing diode should therefore be installed in the COM line of the

load device.

CAUTION: Operator error could result in injury or equipment damage.

WARNING: Operator error could result in serious injury or loss of life.

DANGER: In extreme conditions, there is a possible result of serious

injury or loss of life.

Electrical Wiring D-sub connector

Flat cable connector

S0700-TFJ34GB

Installation and Maintenance Manual

S0700 5 Port Solenoid Valve

EMC directive 89/336/EEC EN 61000-6-2

EN 55011

X

Thread Appropriate tightening torque (Nm)

M3 By hand + ¼ turn with the wrench

M5 By hand + 1/6 turn with the wrench (1/4 turn for miniature fittings)