- 5 -

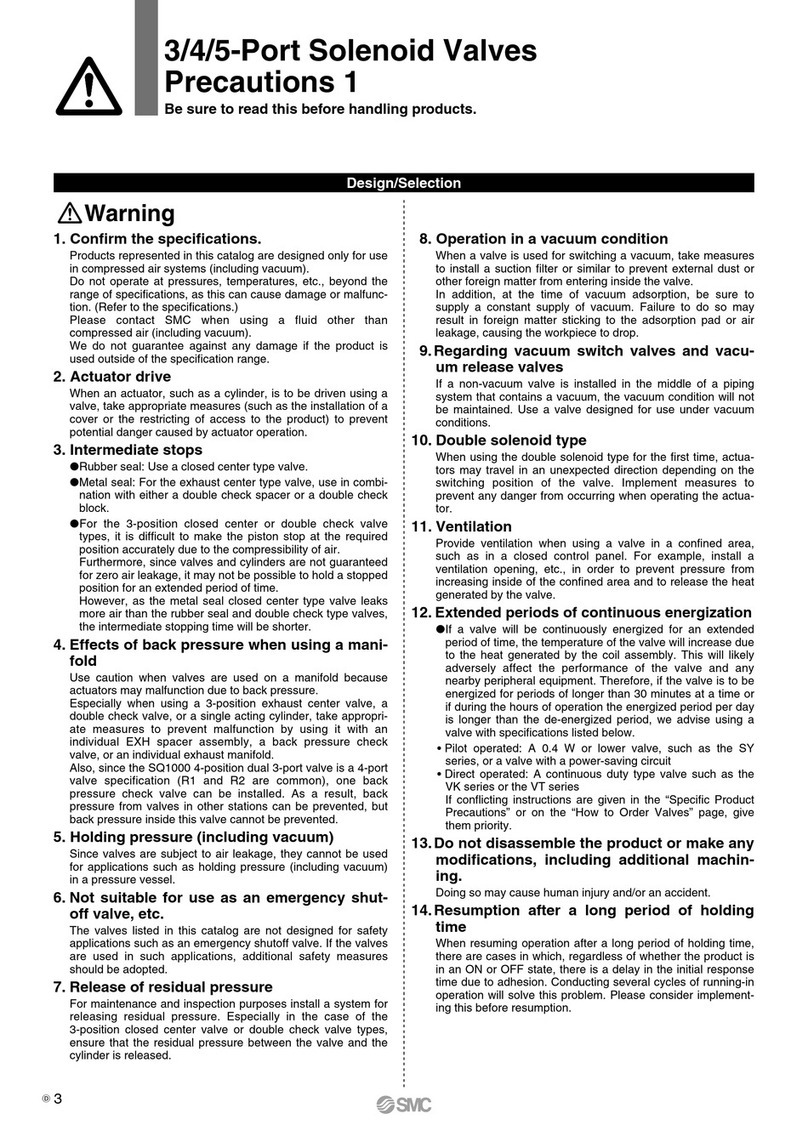

Caution

(3) Check the model, type and size before

installation.

Also, confirm that there are no scratches,

gouges or cracks on the product.

(4) When connecting the tubing, take pressure or

possible changes to the tubing length into

account, and allow a sufficient margin.

Failure to do so may result in fitting breakage or

detachment of the tubing. Refer to the

recommended piping conditions.

(5) Do not apply unnecessary forces such as

twisting, pulling, moment loads, vibration and

impact, etc. on fittings or tubing.

This will cause damage to fittings and will crush,

burst or release tubing.

(6) Tubing, with the exception of coiled tubing,

requires stationary installation. Do not use

standard tubing (non-coiled) in applications

where tubing is required to travel inside the

flexible protection tube. Tubing that travels

may sustain abrasion, extension, or severance

due to tensile force, or may result in removal of

tubing from fitting. Use caution prior to use for

proper application.

(7) To install the fitting, screw the fitting into the

hexagonal face of the body, and tighten with

an appropriate wrench.

Affix the wrench at the base of the thread. If the

size of hexagonal face and wrench do not match,

or tightening takes place near the tube side, it may

cause collapse or deformation of the hexagonal

face, or damage to the equipment. After installing,

confirm that there is no damage to the fitting, etc.

Warning

(1) Type of fluids

Please consult with SMC when using the product

in applications other than compressed air.

Regarding products for general fluids, please

contact SMC concerning applicable fluids.

(2) When there is a large amount of drainage.

Compressed air that contains a large amount of

drainage can cause malfunction of pneumatic

equipment. An air dryer or water droplet separator

should be installed upstream from filters.

(3) Drain flushing

If condensation in the drain bowl is not emptied on

a regular basis, the bowl will overflow and allow

the condensation to enter the compressed air

lines. It causes malfunction of pneumatic

equipment. If the drain bowl is difficult to check

and remove, installation of a drain bowl with an

auto drain option is recommended.

For details on the above compressed air quality,

refer to SMC's Best Pneumatics catalog.

(4) Use clean air.

Do not use compressed air that contains

chemicals, synthetic oils including organic

solvents, salt or corrosive gases, etc., as it can

cause damage or malfunction.

Caution

(1) Install an air filter.

Install an air filter at the upstream side of valve.

Select an air filter with a filtration degree of 5μm

or finer.

(2) Install an after cooler, air dryer or water

droplet separator, etc.

Compressed air that contains a large amount of

drainage can cause malfunction of pneumatic

equipment. Therefore,take appropriate measures

to ensure air quality, such as by providing an

aftercooler, air dryer or water droplet separator.

(3) Ensure that the fluid and ambient temperature

are within the specified range.

If the fluid temperature is 5

o

C or less, the

moisture in the circuit could freeze, causing

damage to the seals and leading to equipment

malfunction. Therefore, take appropriate

measures to prevent freezing.

For details on the above compressed air quality,

refer to SMC's Best Pneumatics catalog.

Warning

(1) Do not use in an atmosphere having corrosive

gases, chemicals, sea water, water, water

steam, or where there is direct contact with

any of these.

Refer to each construction drawing on the

Residual Pressure Release Valve with One-touch

Fitting material.

(2) Do not expose the product to direct

sunlight for an extended period of time.

(3) Do not use in a place subject to heavy

vibration and/or shock.

(4) Do not mount the product in locations

where it is exposed to radiant heat.

(5) Do not use the ordinary fittings and tubing

in locations where static electricity would

be problematic.

It may result in the system failure and trouble.

(6) Do not use the ordinary fittings and tubing

in locations where spatter is generated.

Spattering may result in a fire hazard.

(7) Do not use in an environment where the

product is directly exposed to cutting oil,

lubricant, coolant oil, etc.

Please contact SMC if using for an

environment exposed to cutting oil, lubricant or

coolant oil, etc.

Air Supply

Operating Environment

Mounting/ Piping

Air Supply

2. Specific Product Precautions (2)

2023-01-2514:41

DP056938