SMC Networks VBA40A User manual

Other SMC Networks Controllers manuals

SMC Networks

SMC Networks JXC5H User manual

SMC Networks

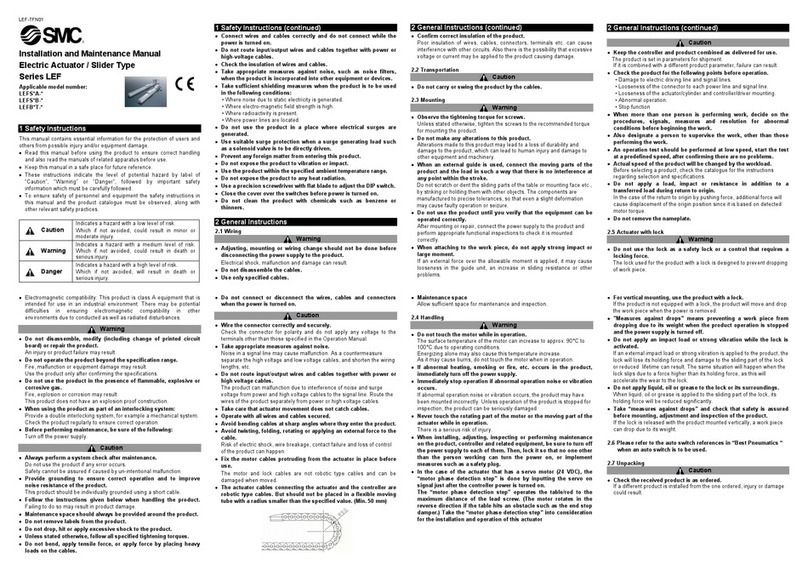

SMC Networks LEF Series User manual

SMC Networks

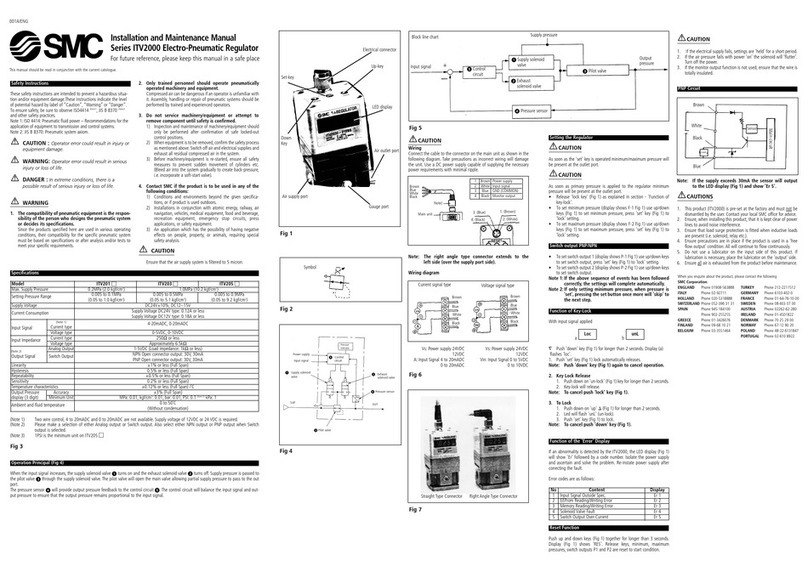

SMC Networks ITV 0 Series User manual

SMC Networks

SMC Networks ITV2000 series Manual

SMC Networks

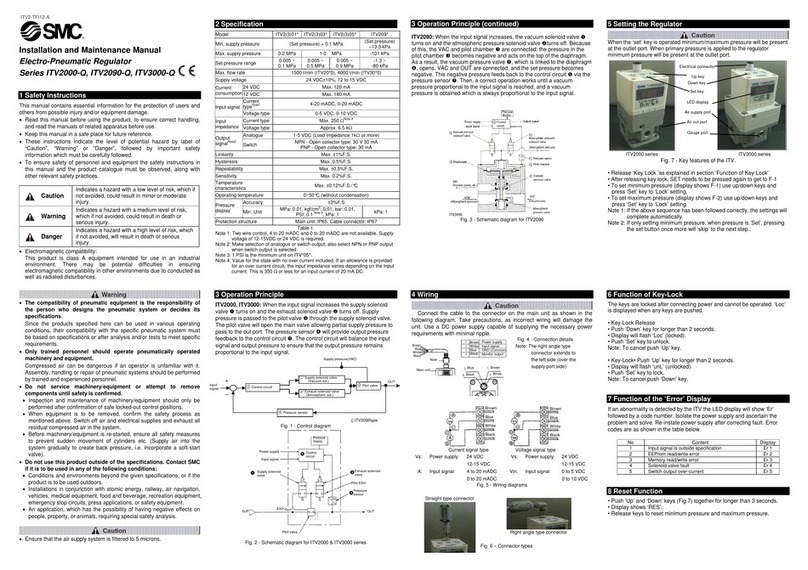

SMC Networks ITV2000-Q Series Manual

SMC Networks

SMC Networks JXCM1 User manual

SMC Networks

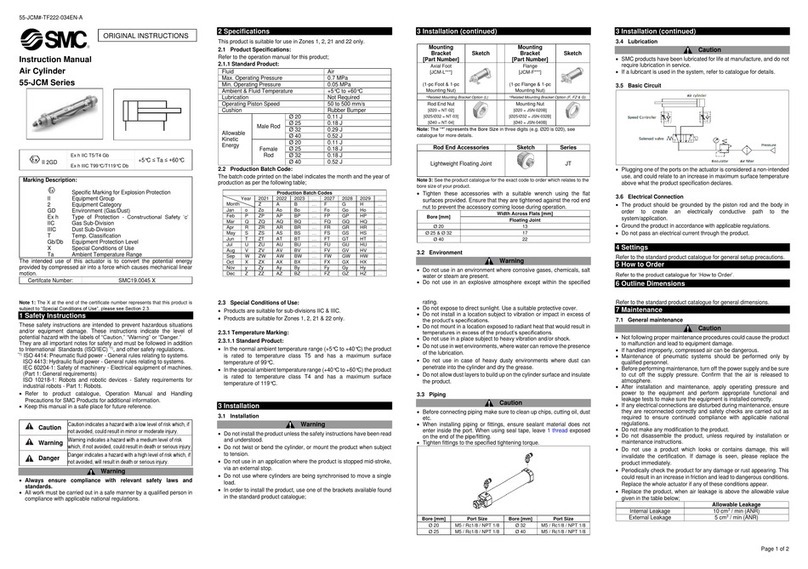

SMC Networks 55-JCM Series User manual

SMC Networks

SMC Networks VBA10A-02-X3239 User manual

SMC Networks

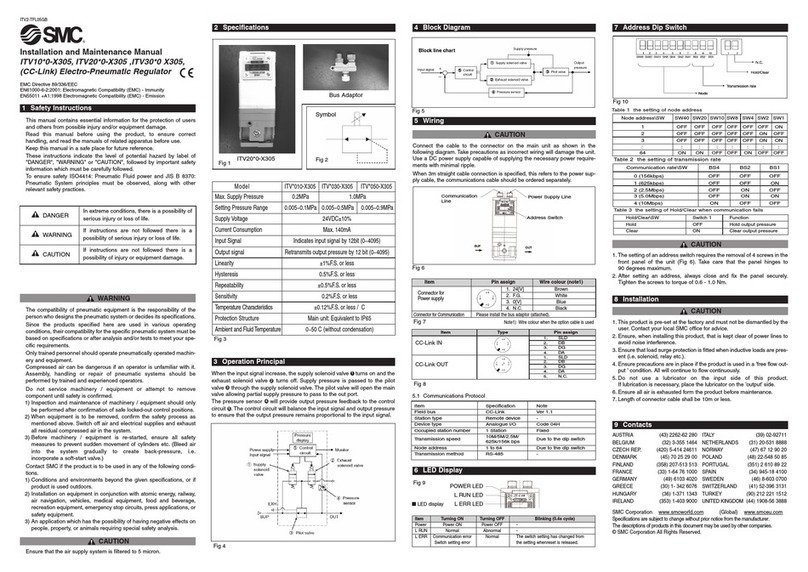

SMC Networks ITV10*0-X305 Manual

SMC Networks

SMC Networks CRJ Series User manual

SMC Networks

SMC Networks IRV10 User manual

SMC Networks

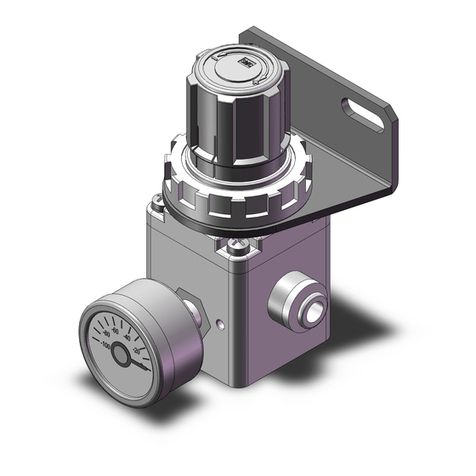

SMC Networks IN502-44 Series User manual

SMC Networks

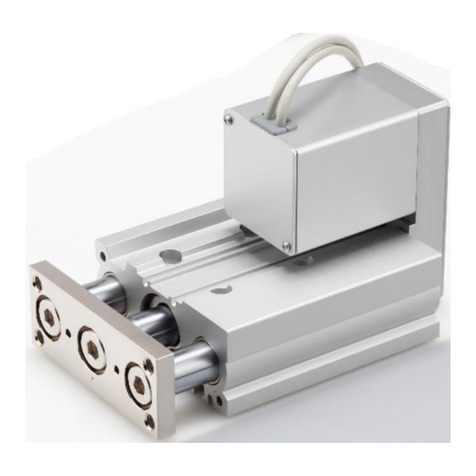

SMC Networks LEFS 16 Manual

SMC Networks

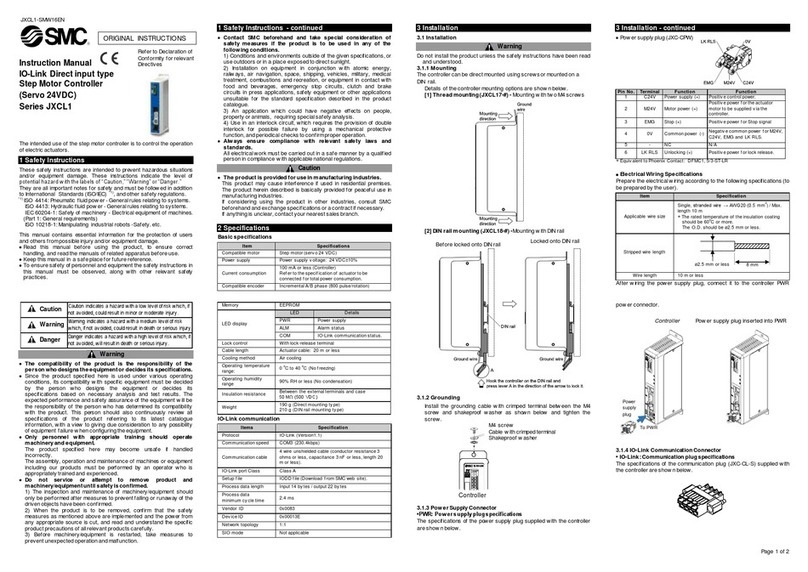

SMC Networks JXCL1 Series User manual

SMC Networks

SMC Networks JAS-L Series User manual

SMC Networks

SMC Networks IR3000-A User manual

SMC Networks

SMC Networks AS-FS A Series User manual

SMC Networks

SMC Networks LEG Series User manual

SMC Networks

SMC Networks PSE20 A Series User manual

SMC Networks

SMC Networks ISA3-FCP-4LB-L1 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions