7

Table of Contents

Introduction

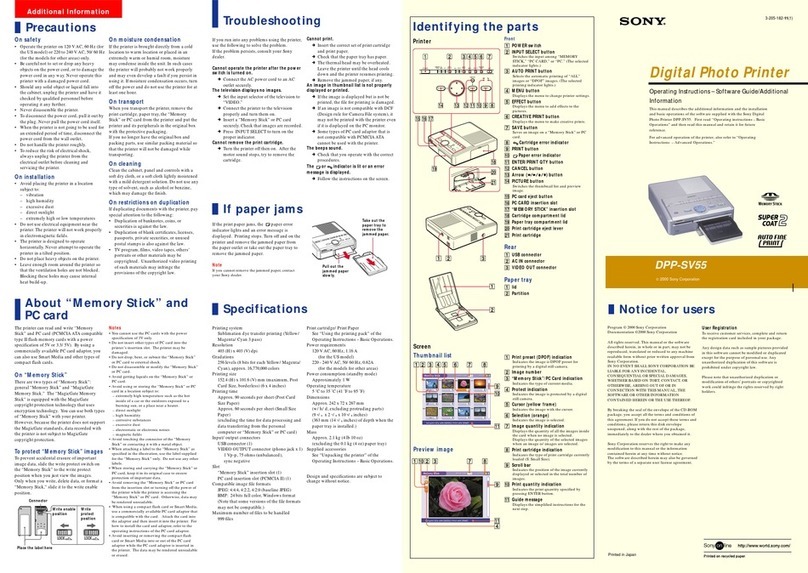

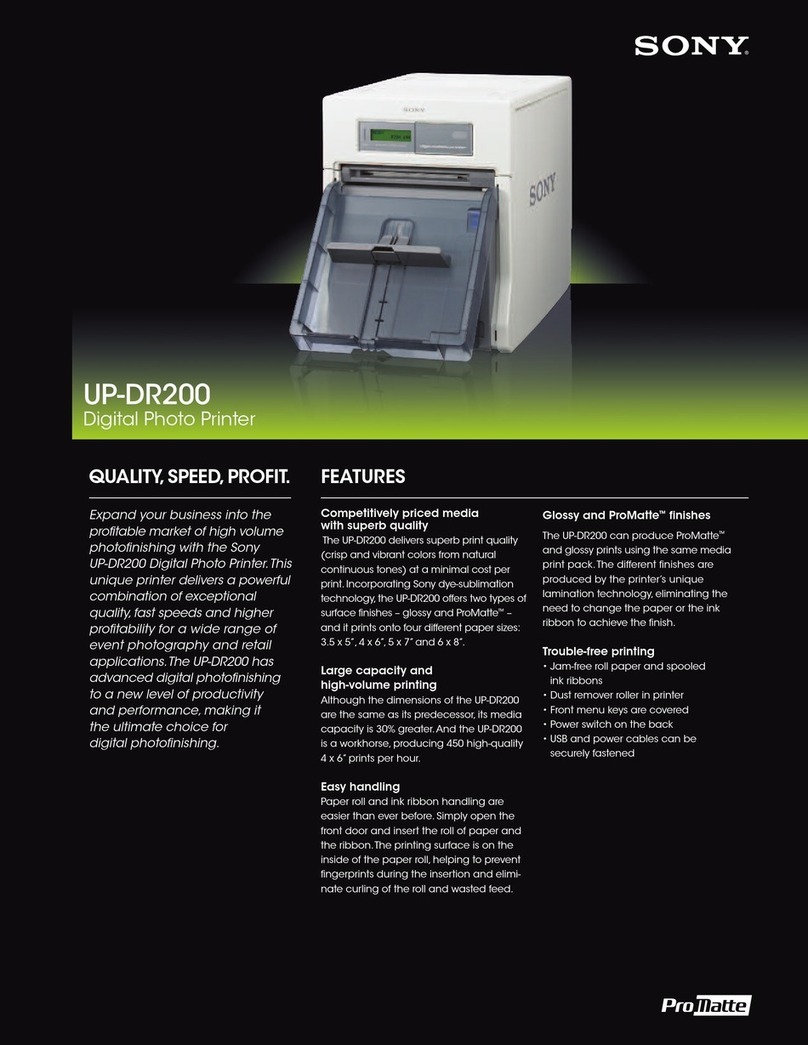

System Overview ....................................................... 8

Location and Function of Parts and Controls ........ 8

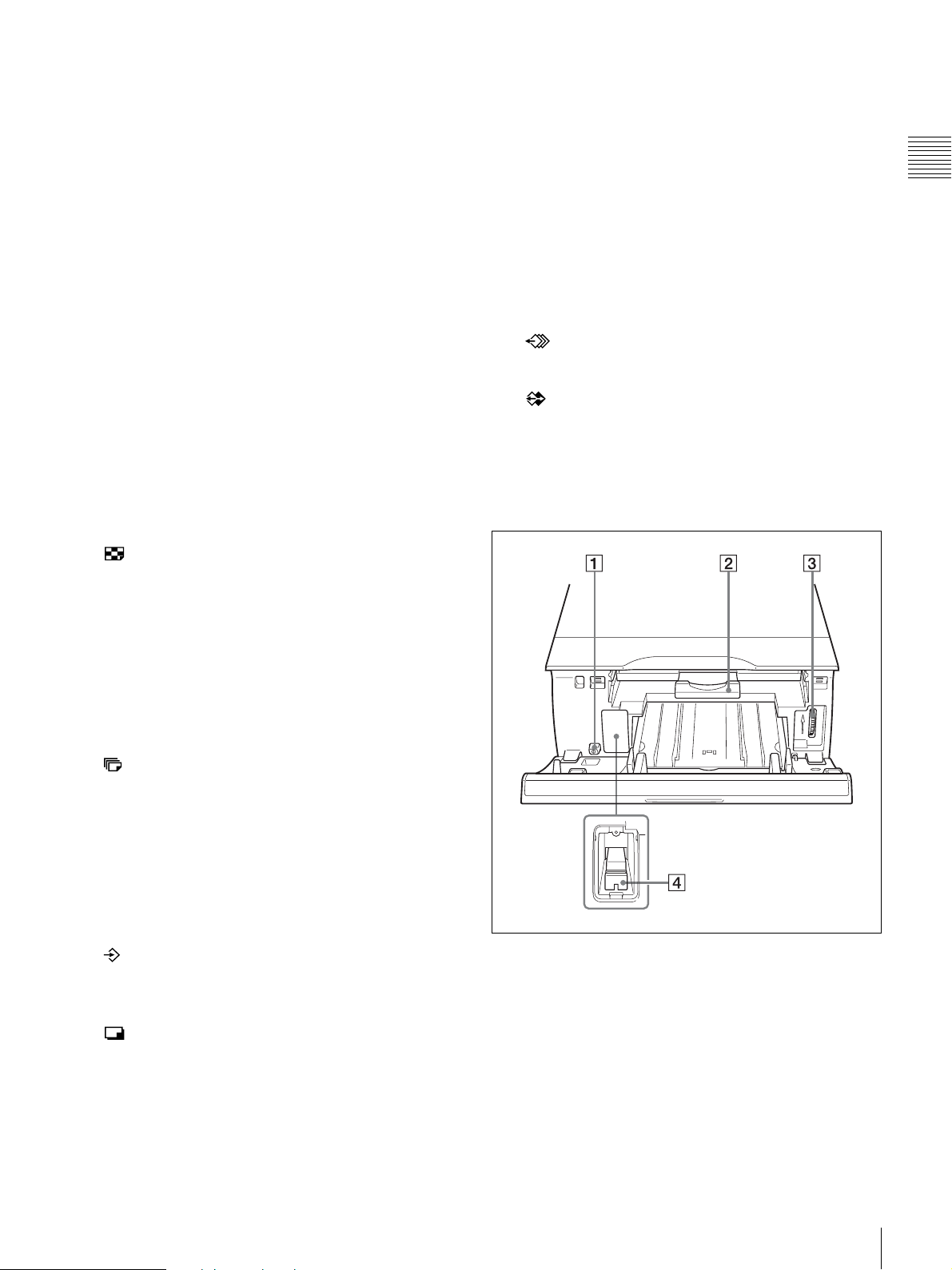

Front ....................................................................... 8

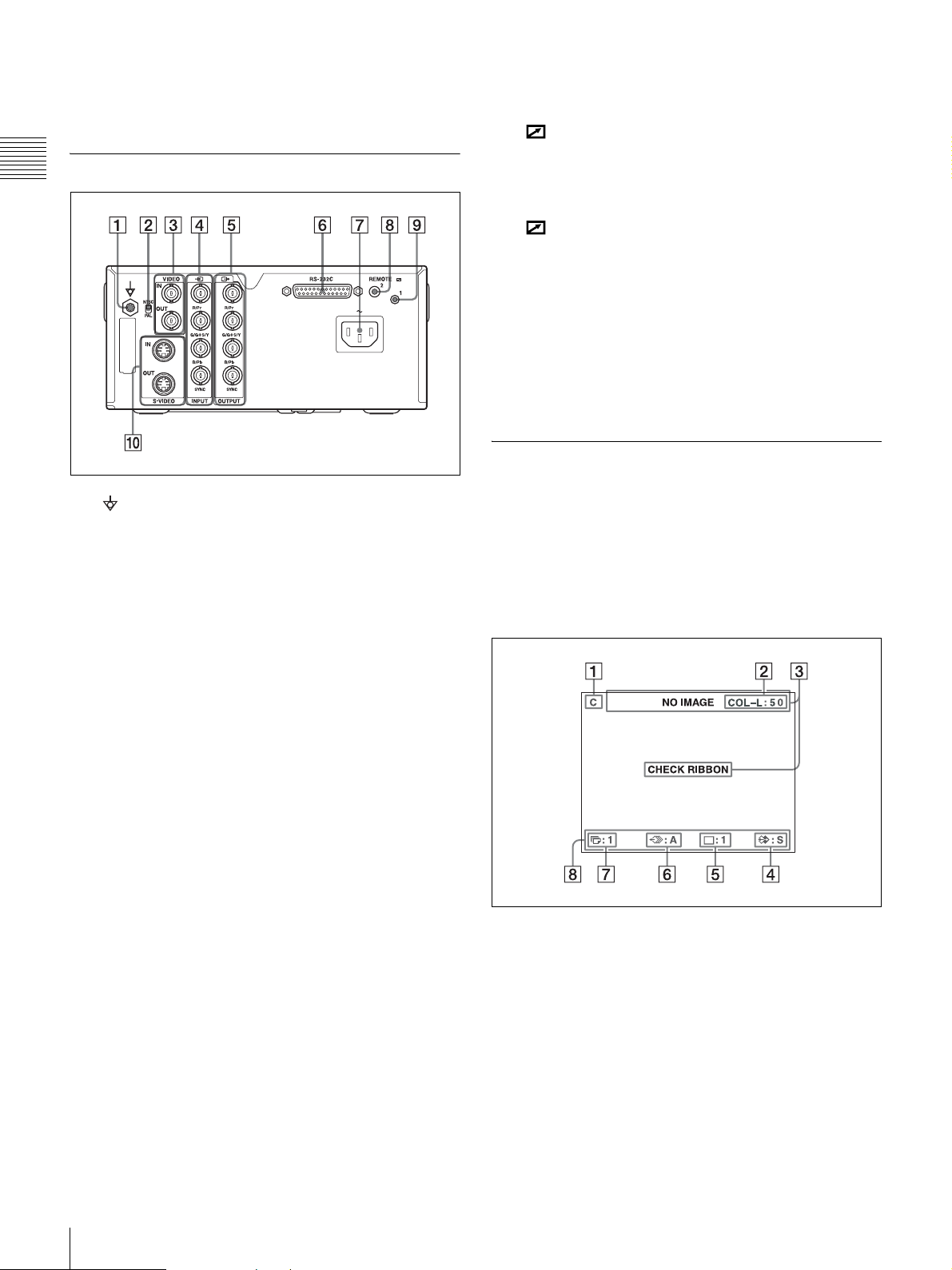

Rear ...................................................................... 10

Monitor Display ................................................... 10

Preparation

Supplied Accessories ............................................... 12

Connections ............................................................. 12

Connecting Video Equipment .............................. 12

Connecting the Video Monitor ............................ 13

Making Connections to Enable Remote

Control ............................................................... 14

Operation

Before Printing ........................................................ 15

Loading the Ink Ribbon ....................................... 15

Loading the Paper ................................................ 17

Selecting the Input Signal .................................... 19

Making Full-Size Image Printouts ........................ 20

Making Printouts with the Desired User Set

Number .............................................................. 23

Making Multiple Copies of Identical Printouts ... 23

Capturing Another Image While Printing ............ 25

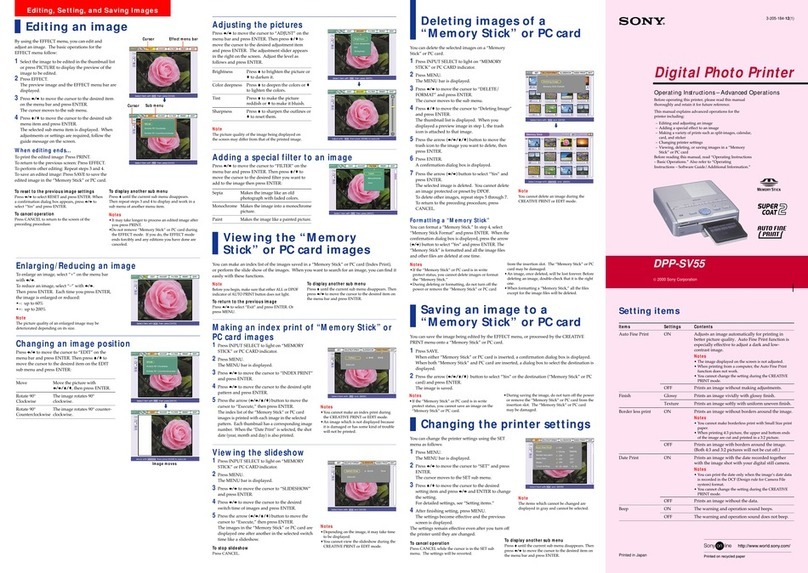

Making Variations of Printouts ............................. 26

Selecting the Memory Mode ............................... 26

Selecting a Memory Page .................................... 28

Making a Printout of Multiple Different Reduced

Images ...................................................................... 29

Making Printouts with a Caption .......................... 33

Making Printouts With a Caption ........................ 33

Entering a Caption ............................................... 33

Deleting Images Stored in Memory ....................... 36

Setting the Function of the STOP/CLEAR

Button ................................................................ 36

Deleting Images Stored in Memory ..................... 37

Erasing the Screen Display on the Video

Monitor .................................................................... 38

Adjustment

Functions That Can be Set on Menus ................... 40

Menu Tree ................................................................ 41

Basic Menu Operations .......................................... 42

Adjusting the Color and Picture Quality .............. 45

Compensating for the Input Signals .................... 45

Matching the Video Monitor Color to the Printer

Color .................................................................. 45

Adjusting the Printout Color ................................ 46

When a Black Frame or Lines Show up on the

Printouts ............................................................. 48

Fitting the Printout to the Paper ........................... 49

Adjusting the Color Balance ................................ 50

Specifying Colors for Adjustment (HSV

Adjustment) ....................................................... 52

Configuring HDTV-Signal Inputs and

Outputs ..................................................................... 57

Selecting the Input Signal .................................... 57

Selecting the Input Signal Type ........................... 57

Selecting the Input Signal Format ....................... 57

Selecting the Synchronization Method for Input

Signals ................................................................ 58

Selecting the Output Signal Type ........................ 58

Selecting the Downconvert Method ..................... 59

Making Various Settings ........................................ 60

Assigning Functions to the Remote Control

Unit .................................................................... 60

Adjusting the Contrast of the Printer Window

Display ............................................................... 61

Setting the Tray Light .......................................... 61

Setting the Cleaning Message Display

Function ............................................................. 61

Selecting Whether the Operation and Error Tones

Sound ................................................................. 61

Setting the Baud Rate .......................................... 62

Printing Menu Configurations ............................. 62

Displaying the Ink Ribbon Type and Remaining

Amount of the Ink Ribbon ................................. 62

Registering a User Set .......................................... 62

Miscellaneous

Precautions .............................................................. 64

Safety ................................................................... 64

Cleaning ............................................................... 64

Cleaning the thermal head and the internal

rollers ................................................................. 65

Ink Ribbon and Paper ............................................ 66

About the Color Printing Pack (UPC-21S/UPC-21L)

and Laminate Color Printing Pack (UPC-24SA/

UPC-24LA) ........................................................ 66

Specifications ........................................................... 67

Troubleshooting ....................................................... 69

If Damage is Suspected ....................................... 69

Error/Warning Messages ....................................... 71

Error Messages .................................................... 71

Warning Messages ............................................... 72

Clearing a Paper Jam ........................................... 74