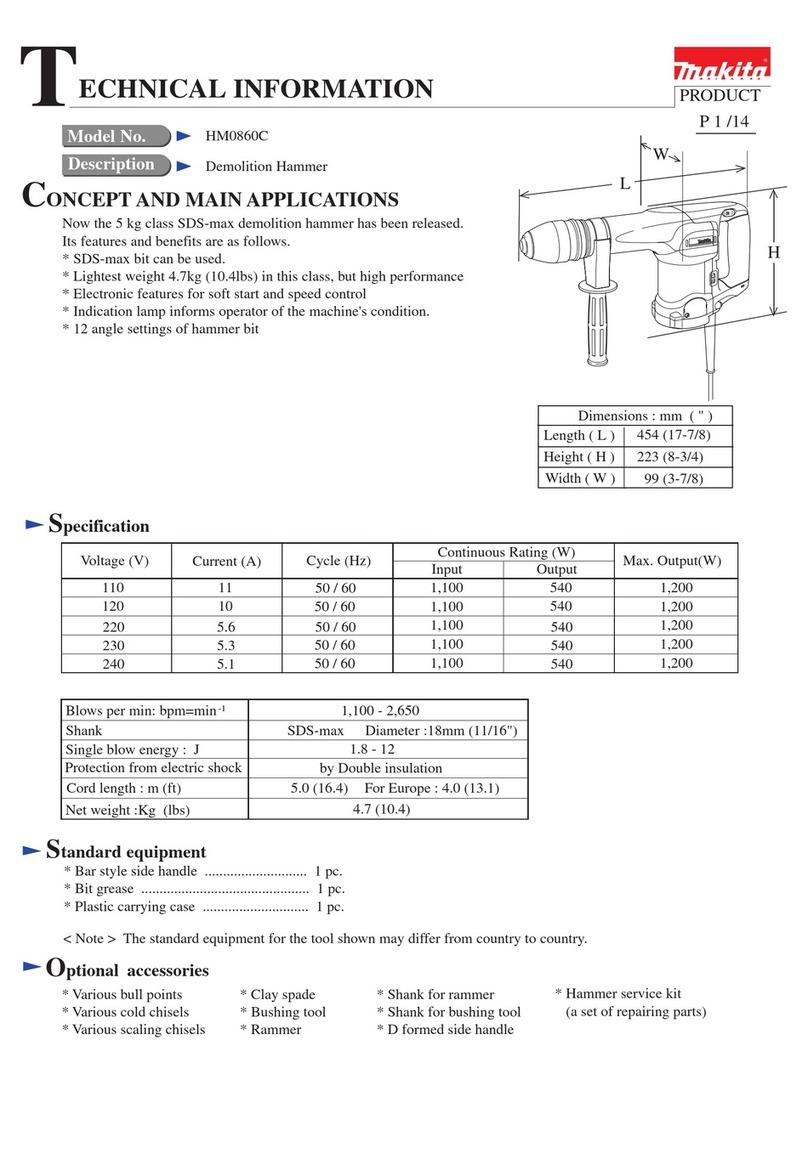

7

NOTE:

The overheat protection works only with a battery

cartridge with a star mark.

Fig.2

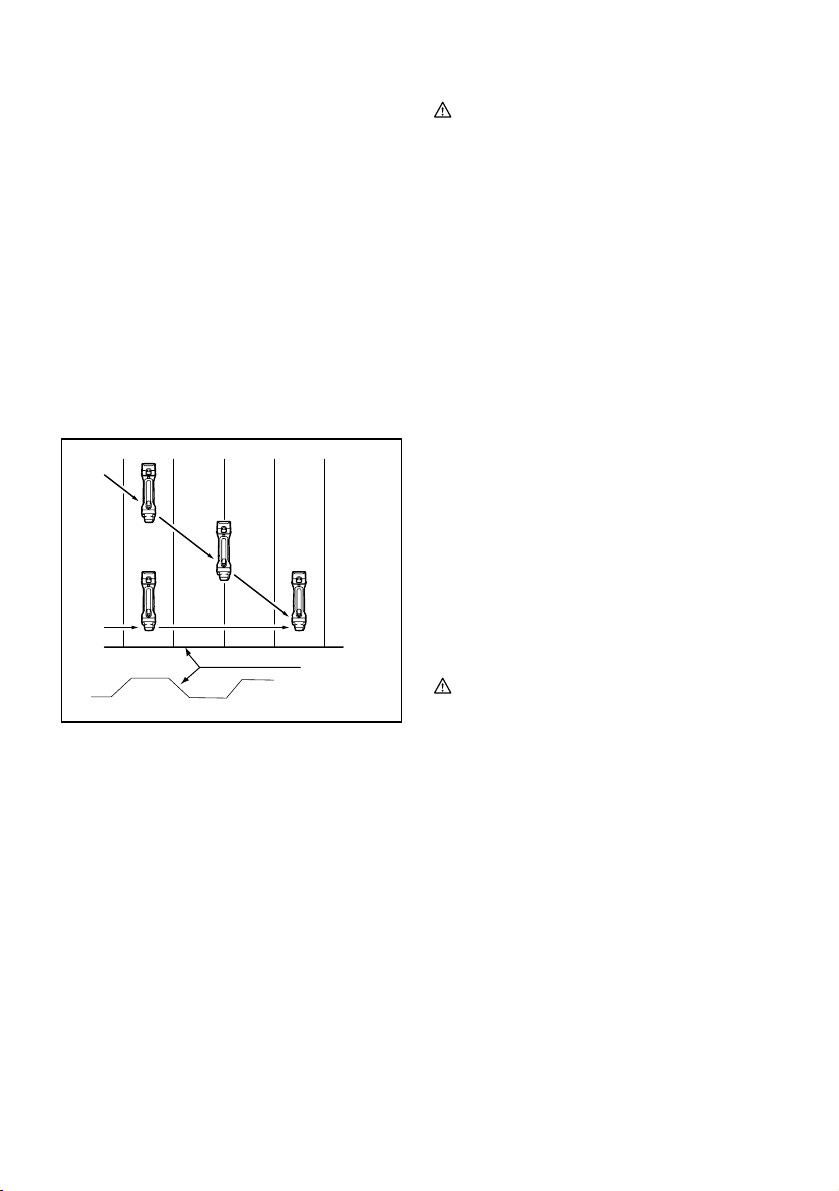

Changing the die position

Fig.3

The die holder position can be changed 360°. To

change it, proceed as follows.

1. Loosen the lock nut with the wrench provided.

2. Pull the die holder slightly and turn it to the

desired position for operation.

3. Tighten the lock nut to secure the die holder in

the desired position.

There are four positive stops at 90° each: 0°, 90° left

and right and 180°. To position the die to any of these

positive stops:

4. Loosen the lock nut with the wrench provided.

5. Pull the die holder slightly and depress lightly

while turning it to the desired position. The die

holder will lock into one of the positive stop

positions as desired.

6. Turn the die holder slightly to make sure that it is

positively locked into position.

7. Tighten the lock nut to secure the die holder.

Permissible cutting thickness

Fig.4

The thickness of material to be cut depends upon the

tensile strength of the material itself. The groove on the

die holder acts as a thickness gauge for allowable

cutting thickness. Do not attempt to cut any material

which will not fit into this groove.

Cutting line

The notch in the die holder indicates your cutting line.

Its width is equal to the cutting width. Align the notch to

the cutting line on the workpiece when cutting.

Switch action

Fig.5

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the slide switch actuates

properly and returns to the "OFF" position when

the rear of the slide switch is depressed.

• Switch can be locked in "ON" position for ease of

operator comfort during extended use. Apply

caution when locking tool in "ON" position and

maintain firm grasp on tool.

To start the tool, slide the slide switch toward the "I

(ON)" position. For continuous operation, press the front

of the slide switch to lock it.

To stop the tool, press the rear of the slide switch, then

slide it toward the "O (OFF)" position.

Indication lamp with multi function

Fig.6

Indication lamps are located in two positions.

−Battery cartridge replacing signal

−When the battery power is almost used up

during operation, the red lamp lights up and

the tool stops immediately. Replace the

battery with fully charged one when the red

lamp lights up.

−Accidental re-start preventive function

−Even if the battery cartridge is inserted on

the tool with the slide switch in the "I (ON)"

position, the tool does not start. At this time,

the lamp flickers slowly and this shows that

the accidental re-start preventive function is

at work.

−To start the tool, first slide the slide switch

toward the "O (OFF)" position and then slide

it toward the "I (ON)" position.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out

any work on the tool.

Removing or installing the punch and die

Fig.7

Always replace the punch and die as a set. To remove

the punch and die, loosen the lock nut with the wrench.

Remove the die holder from the tool. Use the hex

wrench to loosen the bolts which secure the die.

Remove the die from the die holder.

Use the hex wrench to loosen the screw which secures

the punch. Pull the punch out of the punch holder.

Fig.8

To install the punch and die, insert the punch into the

punch holder so that the notch in the punch faces

toward the screw. Tighten the screw to secure the

punch. Install the die on the die holder. Tighten the bolts

to secure the die.

Fig.9

Then install the die holder on the tool so that the punch

is inserted through the hole in the die holder. Tighten the

lock nut to secure the die holder. After replacing the

punch and die, lubricate them with machine oil and run

the tool for a while.

Fig.10