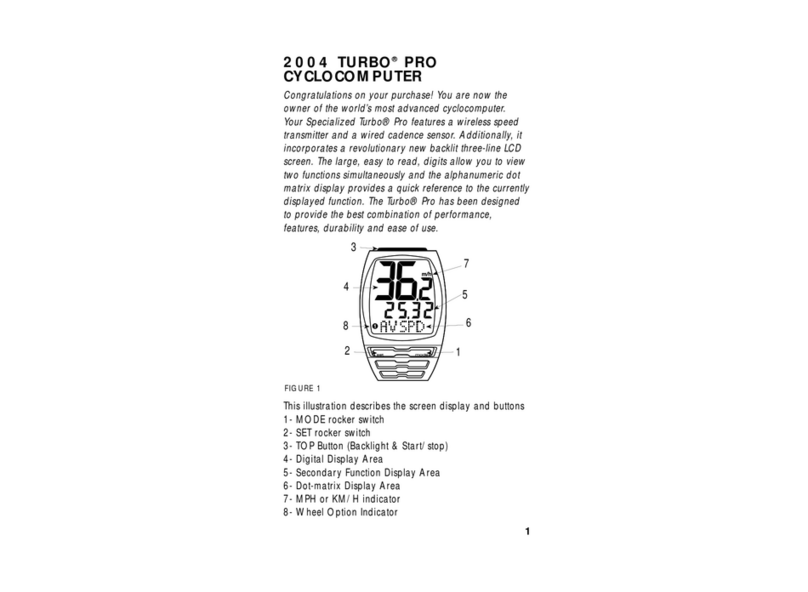

INSTALLATION GUIDE

COMMAND POST ADJUSTABLE HEIGHT SEAT POST

INTRODUCTION

The Command Post seat post provides riders with a way to adjust their saddle height

without tools. Although created by the Specialized Suspension team, the Command Post is

NOT a suspension seat post.

Visit a Specialized authorized dealer if you have any doubt regarding your mechanical

prociency and/or ability to install this product. Specialized recommends that the

Command Post be installed by a qualied bicycle mechanic.

Please read and understand all the warnings. Failure to follow a warning may result in a

catastrophic failure of the Command Post, resulting in serious personal injury or death.

This phrase may not be repeated in connection with each and every warning.

TERMINOLOGY

Power position: When the Command Post is at full height. Used when full power

is needed, such as climbing a long, steep hill or riding a smooth, at section. This

position provides the full 100mm of available seat post height.

Cruiser position: When the Command Post is in the middle position. Used for

pedaling on undulating terrain. This position is 35mm below the Power position.

Descender position: When the Command Post is at its lowest position. Used for

riding downhill/freeride terrain. This position is 100mm below the Power position.

Remote Lever: Used to actuate the Command Post.

INSTALLATION

Take the following items into consideration before installing and using the Command Post.

The air pressure in the Command Post is factory set to 25 psi. Air pressure

determines the speed at which the Command Post rises. See SETUP AND USE for

more information.

The Command Post is 30.9mm in diameter. Prior to installation, ensure that this

diameter conforms to the diameter of the seat tube.

WARNING! Incorrect sizing interface can result in Command Post slippage or

failure, causing serious personal injury or death.

The Command Post should not have any play inside the frame.

The Command Post should slide into the seat tube in a straight, smooth fashion.

The seat collar should be positioned so that the slot faces forward to minimize dirt

contamination from the rear wheel.

If the Command Post exhibits any t and/or torque issues, it is recommended that

the t tolerance be veried by a Specialized Authorized Dealer.

INSTALLING THE COMMAND POST

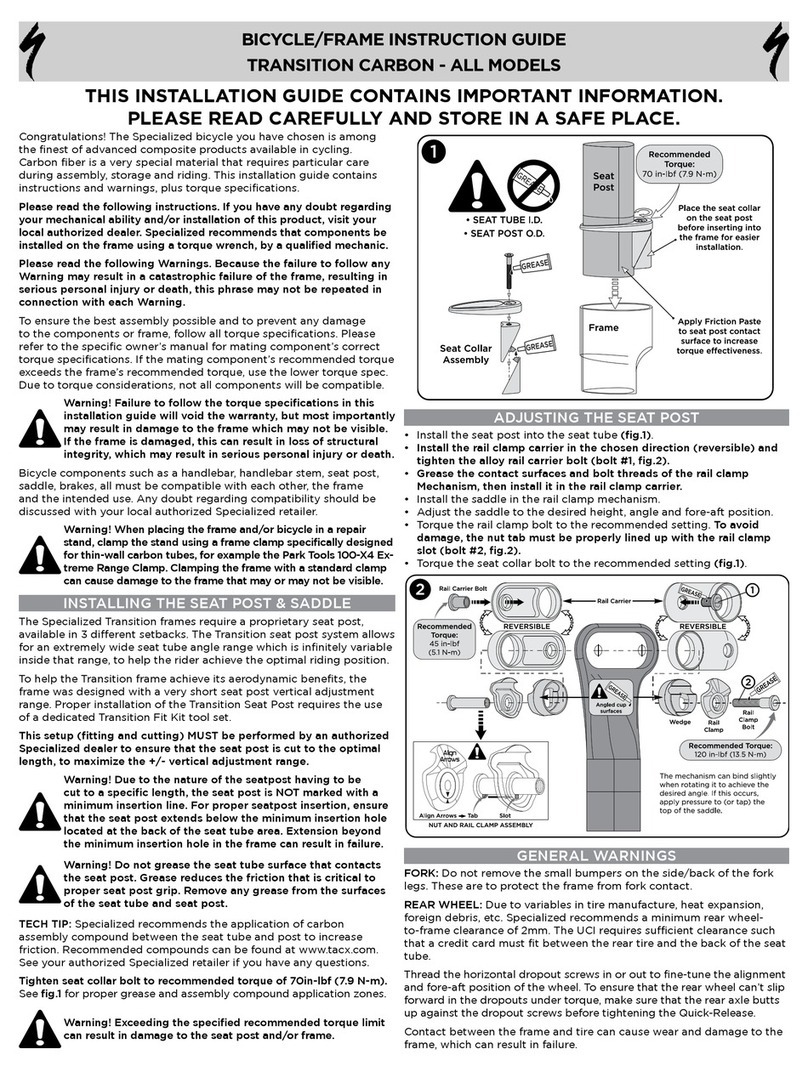

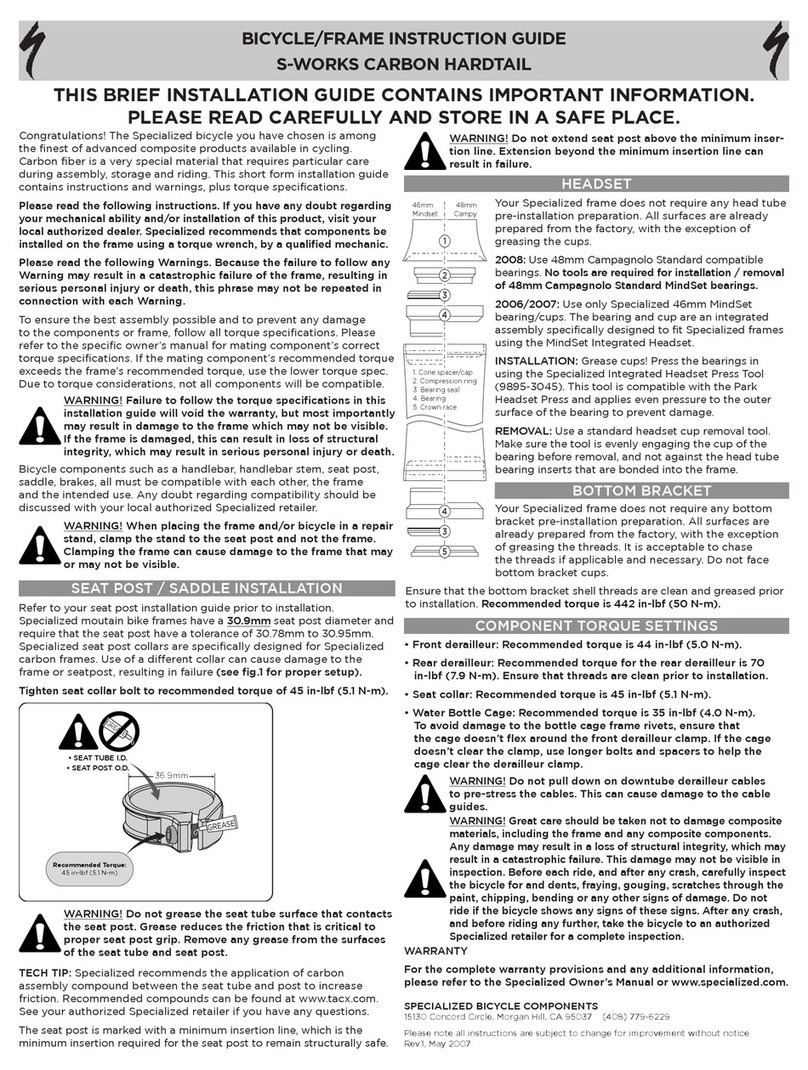

On non-carbon frames only1. , grease the seat tube I.D. and Command Post O.D. (see g.

2).

Slide the Command Post into the seat tube.2.

Adjust the Command Post to approximate height for proper leg extension. The 3.

Command Post ships in the Power (full height) position. While in the Power position,

determine saddle height like you would a standard seat post.

Leave the Command Post in the Power position during installation. This will

ensure that the cable housing is at the correct length.

Adjust seat collar torque to recommended setting (see g. 2).4.

IMPORTANT! Recommended torques in this manual are specic for the Command

Post. Consult the bicycle owner’s manual for recommended torque. Always use

lower torque recommendation.

WARNING! Only use seat collars approved by Specialized with the Command

Post. Use of an unapproved seat collar may result in slippage and potential

damage of the Command Post.

The following 30.9 collars have been tested and recommended:

Specialized xed and Q/R collars

Salsa Flip-Lock Q/Rs

Please visit www.specialized.com for future approved collars.

NOTE: Do not overtighten. Use only hand pressure on Q/R lever. Only use enough tension

to keep the post from slipping. If you are having slipping issues, friction compound pastes or

talc powder can be used on aluminum and carbon frames.

WARNING! Seat collar torque requirements can vary depending on the specic

frame and seat clamp used. Exceeding the max specied torque limit (see g. 2)

can result in damage to the Command Post and/or frame. Consult an authorized

dealer for additional information.

1

NUT AND RAIL CLAMP ASSEMBLY

WEDGE

NUT

ALIGN ARROWS TA B SLOT

RAIL

CLAMP

BOLT

CARBON

FRAMES

• SEAT COLLAR I.D.

NON-CARBON

FRAMES

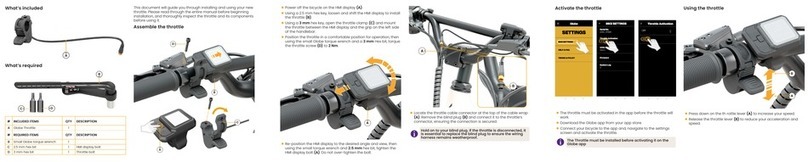

INSTALLING THE REMOTE LEVER

The remote lever is connected by cable to the Command Post. A left-handed remote lever

ships with the Command Post; however, the remote lever can be positioned on either side

of the handlebar, if desired.

NOTE: If saddle is already installed, rotate the saddle out of the way, leaving the saddle head

lever exposed.

To install the remote lever:

Determine which side the remote lever will be installed on (see g. 3). 1.

LEFT-HANDED

REMOTE LEVER

(CAN BE MOUNTED

ON RIGHT SIDE)

3

LEFT GRIP

DEVICES

(BRAKE, SHIFTER)

RIGHT-HANDED

REMOTE LEVER

(NOT INCLUDED)

RIGHT GRIP

DEVICES

(BRAKE, SHIFTER)

Unscrew the hex on the remote lever using a 4mm hex key, and lightly grease the clamp 2.

I.D. (see g. 4).

CARBON

HANDLEBARS

NON-CARBON

HANDLEBARS

REMOTE LEVER I.D.

NO GREASE!

15 in-lbf (1.7 N-m)

4

4MM

NOTE: Do NOT apply grease if the remote lever is to be installed on carbon handlebars.

Clamp the remote lever on the handlebar, ensuring that the remote lever is the handlebar 3.

device closest to the stem (see g. 3). Before installing and tightening the hex screw,

operate the remote lever to ensure it doesn’t impede on other devices already on the

handlebar, such as shifters and brake levers.

Screw the hex on the clamp and torque to 15 in/lbs. using a torque wrench and a 4mm 4.

hex key (see g. 4).

Insert the cable through the slot on the remote lever. Pull through until the cable head 5.

rests in the slot (see g. 5).

Insert the cable into the 90-degree pipe, making sure to insert the cable through the 6.

non-grommeted end (see g 5).

CABLE HEAD

FERRULE

CABLE TO

SEAT POST

SLOT

RUN CABLE

THROUGH

90-DEGREE

PIPE

PULL CABLE

UNTIL CABLE

HEAD RESTS

IN SLOT

INSERT CABLE

THROUGH SLOT

NON-GROMMETED END

5b

c

d

a

INSERT CABLE

INTO NON-FERRULE

END OF CABLE

HOUSING

(con’t.)