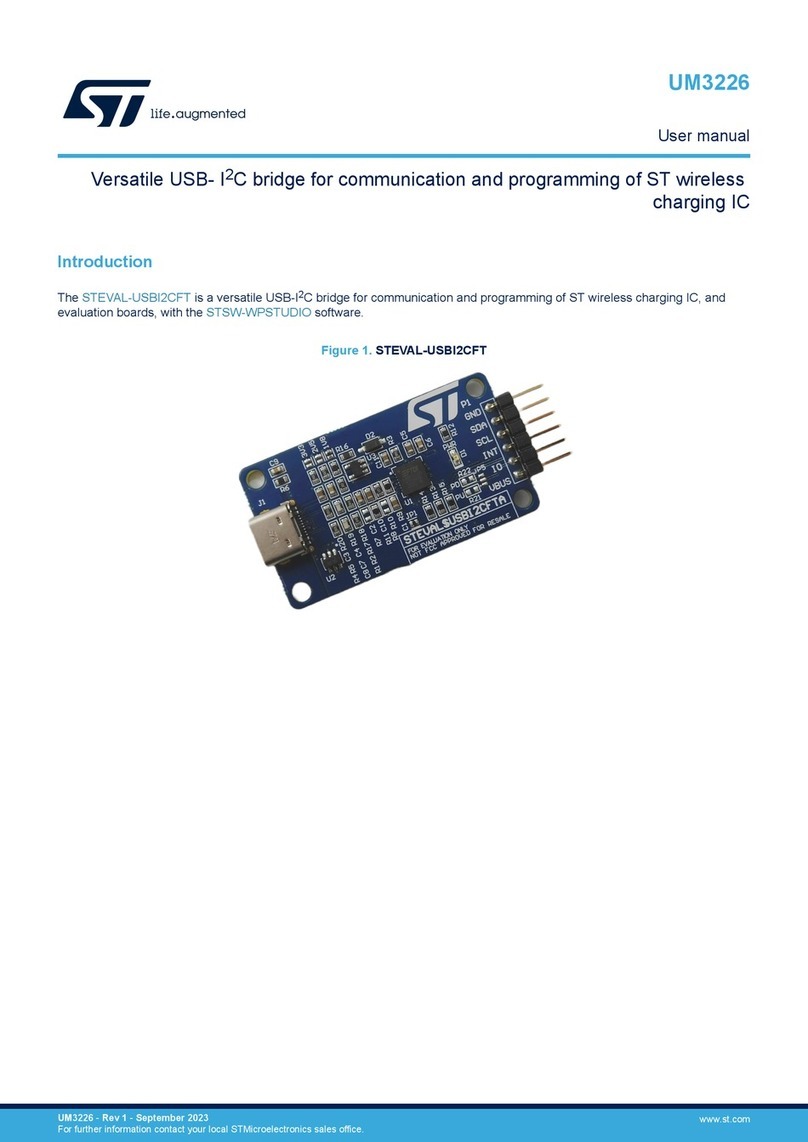

ST AEK-LCD-DT028V1 User manual

Other ST Computer Hardware manuals

ST

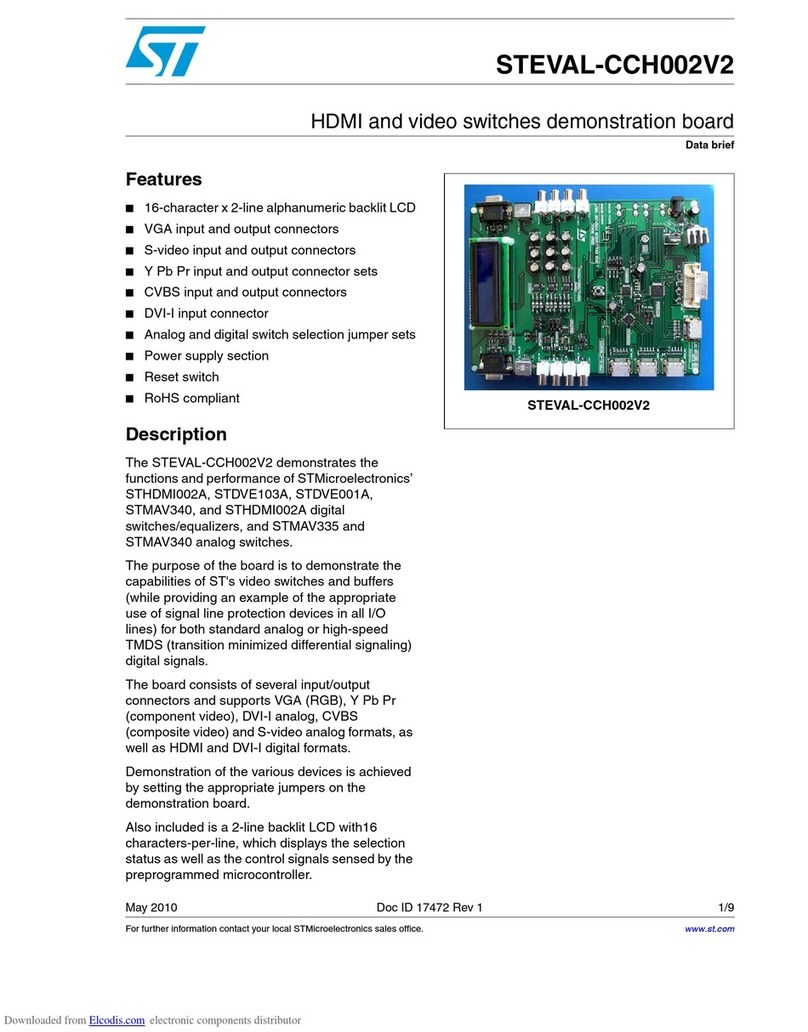

ST STEVAL-CCH002V2 User manual

ST

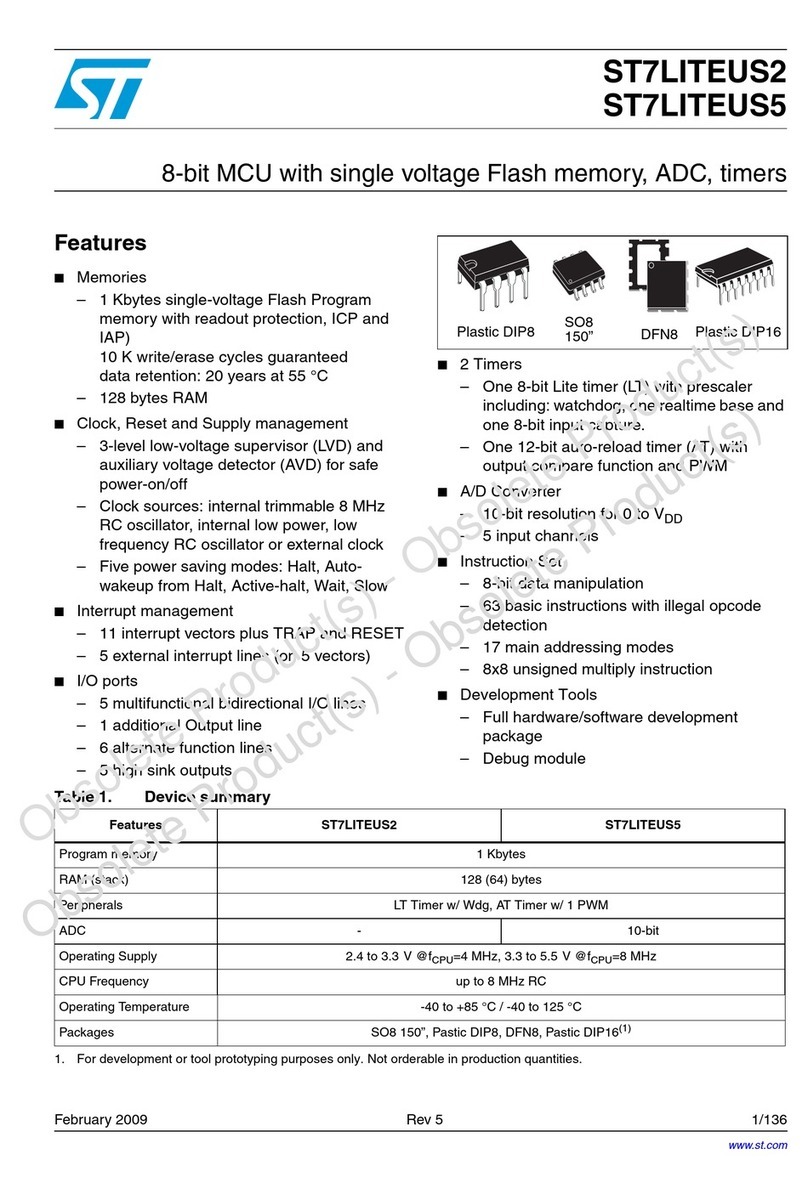

ST ST7LITEUS2 User manual

ST

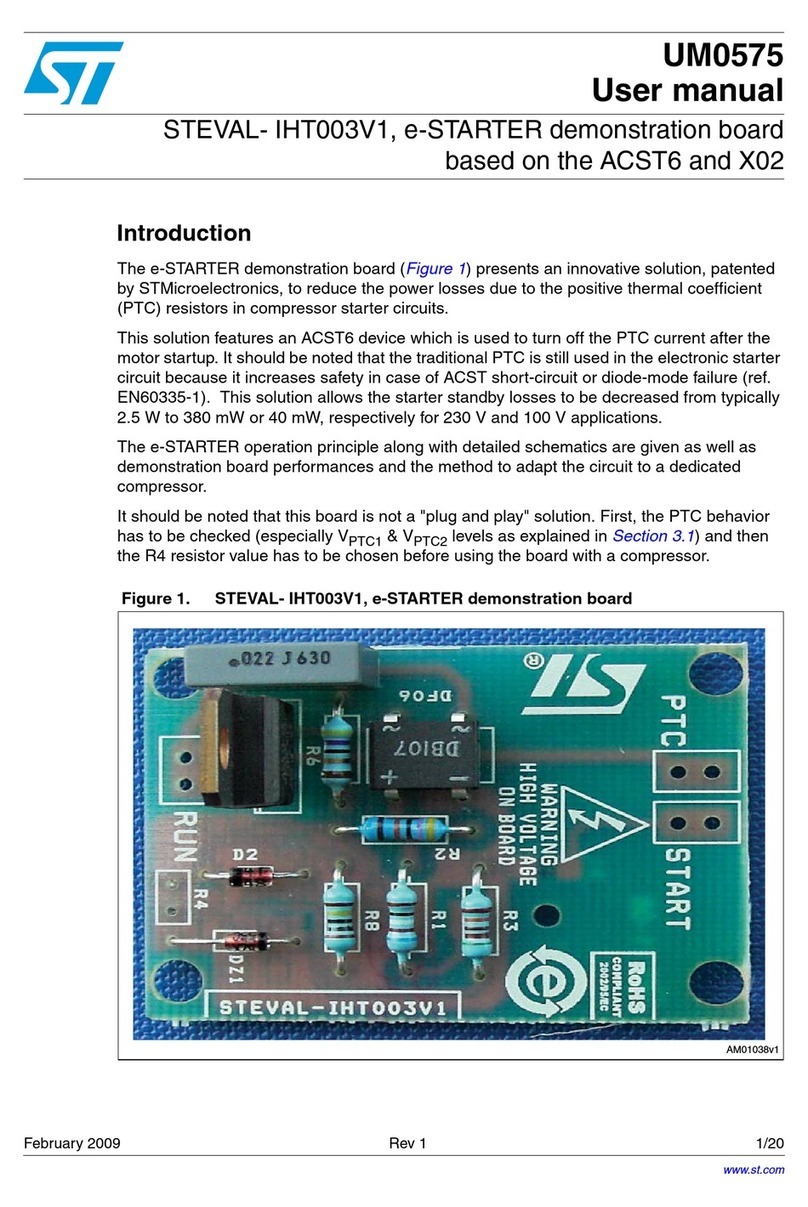

ST UM0575 User manual

ST

ST STM32F10 Series Installation and operating instructions

ST

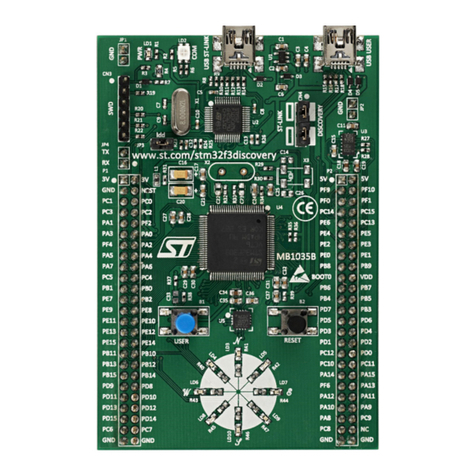

ST STM32F3DISCOVERY User manual

ST

ST STSW-ST25DV002 User manual

ST

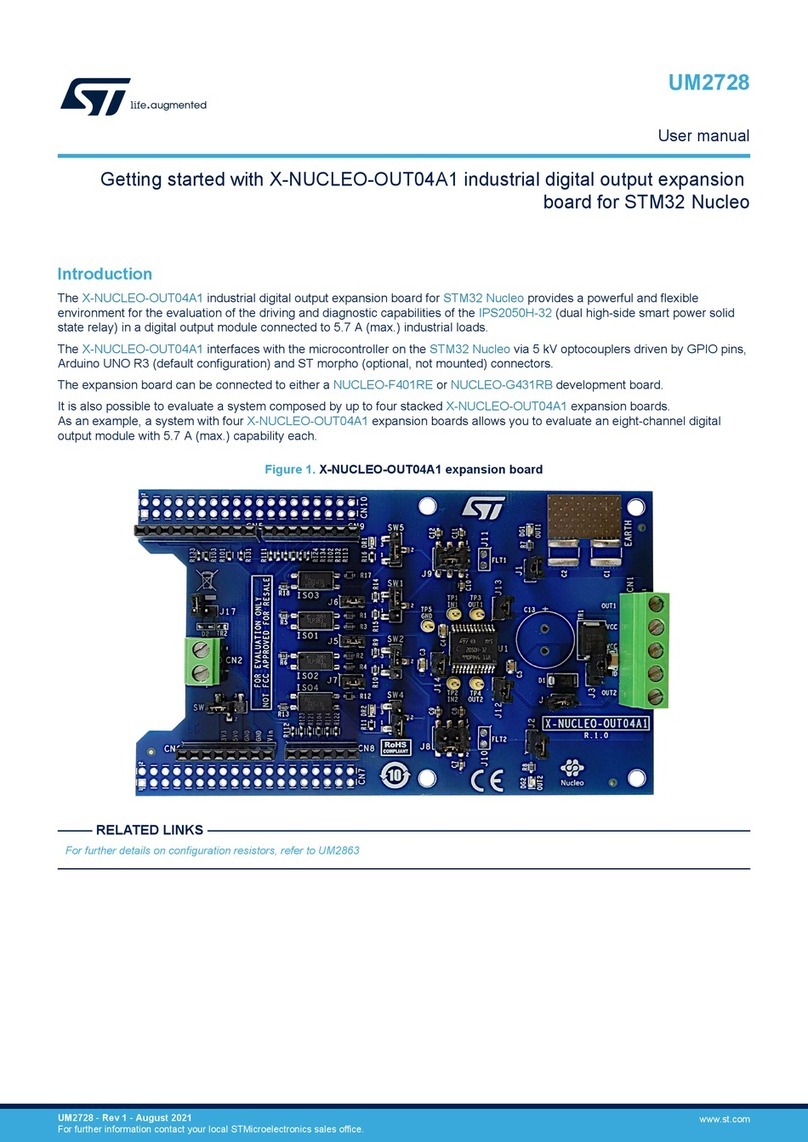

ST X-NUCLEO-OUT04A1 User manual

ST

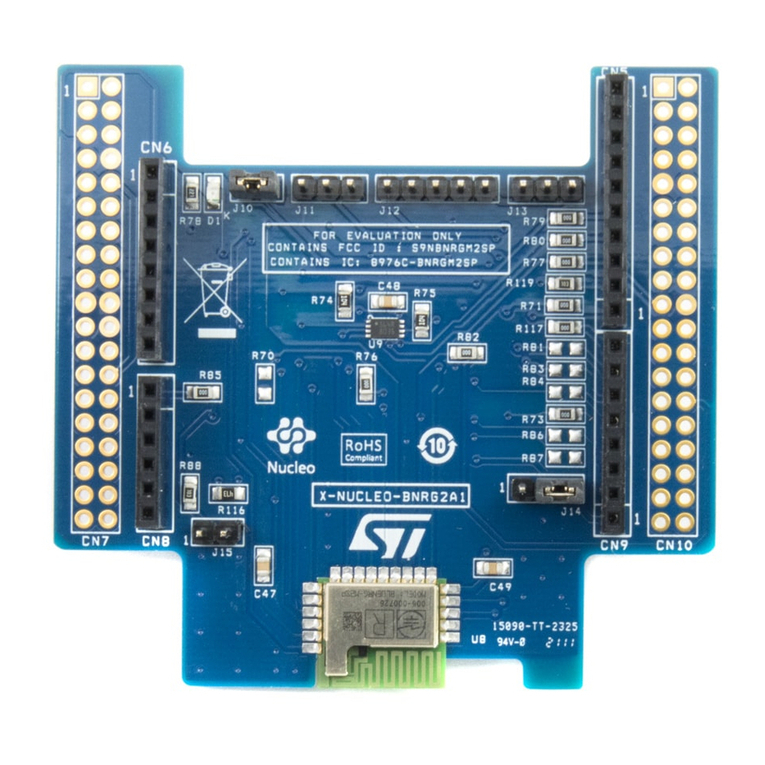

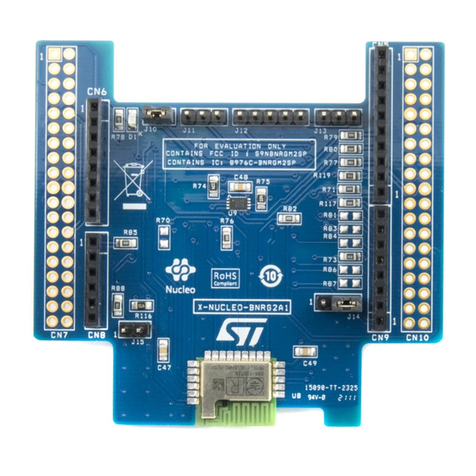

ST X-NUCLEO-BNRG2A1 User manual

ST

ST X-NUCLEO-IDB05A2 User manual

ST

ST STM32L562E-DK User manual

ST

ST X-NUCLEO-LED12A1 User manual

ST

ST CLT01-38SQ7 User manual

ST

ST X-NUCLEO-GNSS2A1 User manual

ST

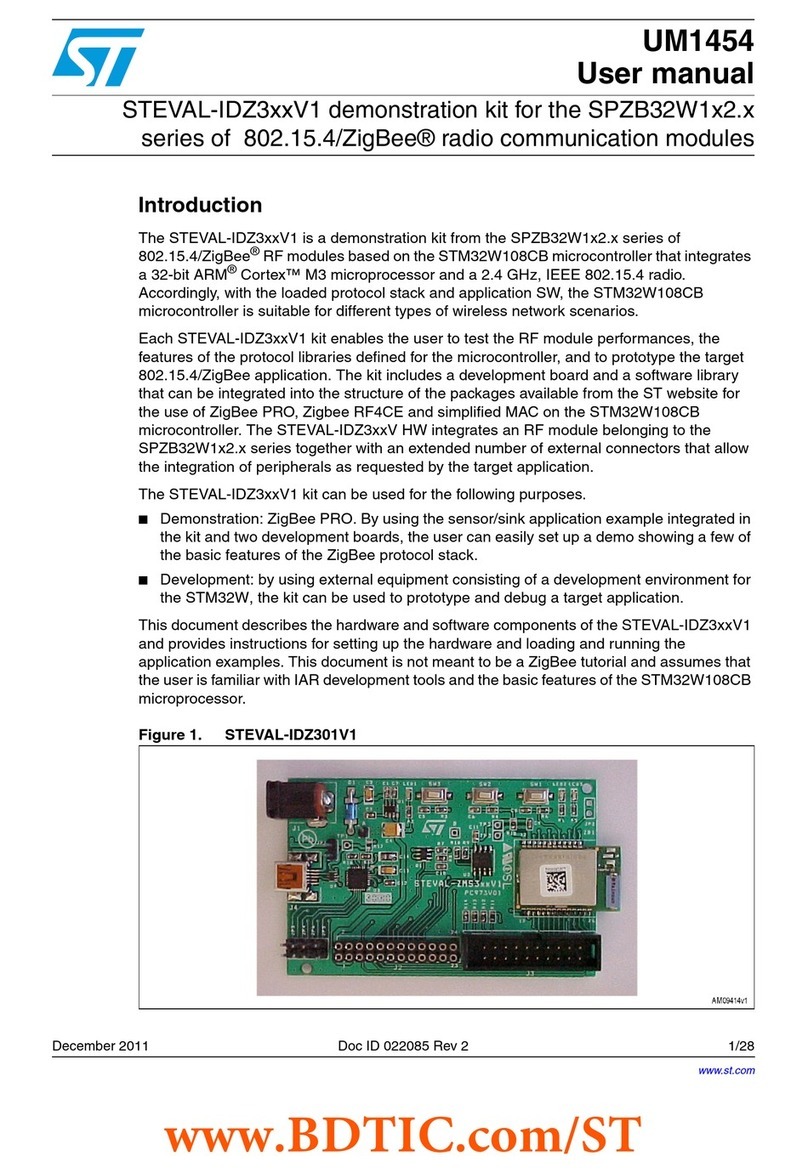

ST STEVAL-IDZ3V1 Series User manual

ST

ST UM2033 User manual

ST

ST X-NUCLEO-NFC01A1 User manual

ST

ST X-NUCLEO-IHM09M1 User manual

ST

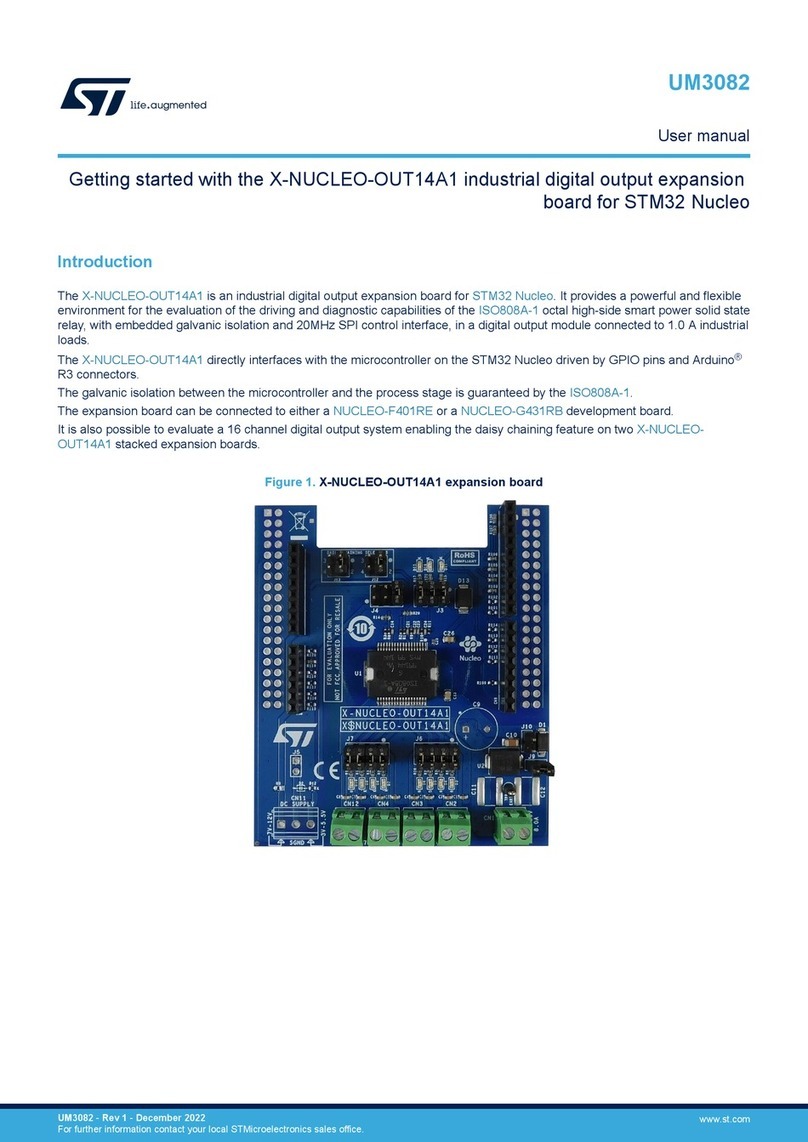

ST X-NUCLEO-OUT14A1 User manual

ST

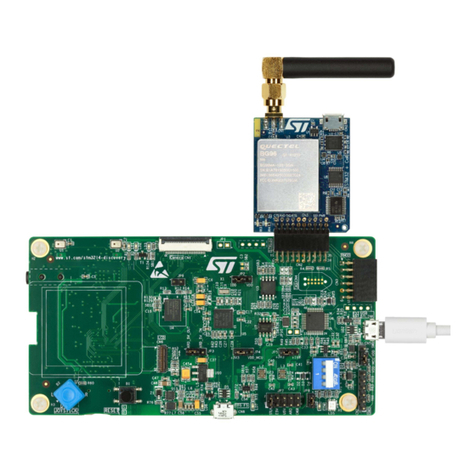

ST X-CUBE-CELLULAR User manual

ST

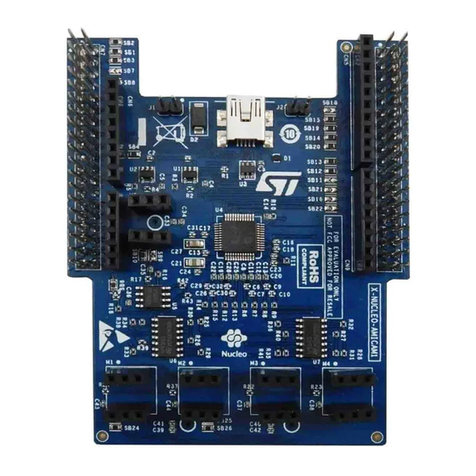

ST X-NUCLEO-AMICAM1 User manual

Popular Computer Hardware manuals by other brands

EMC2

EMC2 VNX Series Hardware Information Guide

Panasonic

Panasonic DV0PM20105 Operation manual

Mitsubishi Electric

Mitsubishi Electric Q81BD-J61BT11 user manual

Gigabyte

Gigabyte B660M DS3H AX DDR4 user manual

Raidon

Raidon iT2300 Quick installation guide

National Instruments

National Instruments PXI-8186 user manual

Intel

Intel AXXRMFBU4 Quick installation user's guide

Kontron

Kontron DIMM-PC/MD product manual

STEINWAY LYNGDORF

STEINWAY LYNGDORF SP-1 installation manual

Advantech

Advantech ASMB-935 Series user manual

Jupiter

Jupiter RAM PACK instructions

Measurement Computing

Measurement Computing CIO-EXP-RTD16 user manual