ST STLINK-V3PWR User manual

Other ST Computer Hardware manuals

ST

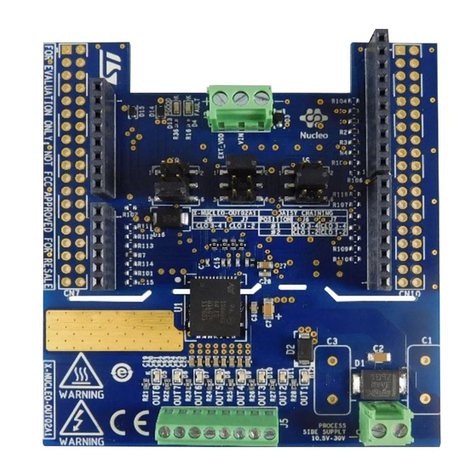

ST X-NUCLEO-OUT02A1 User manual

ST

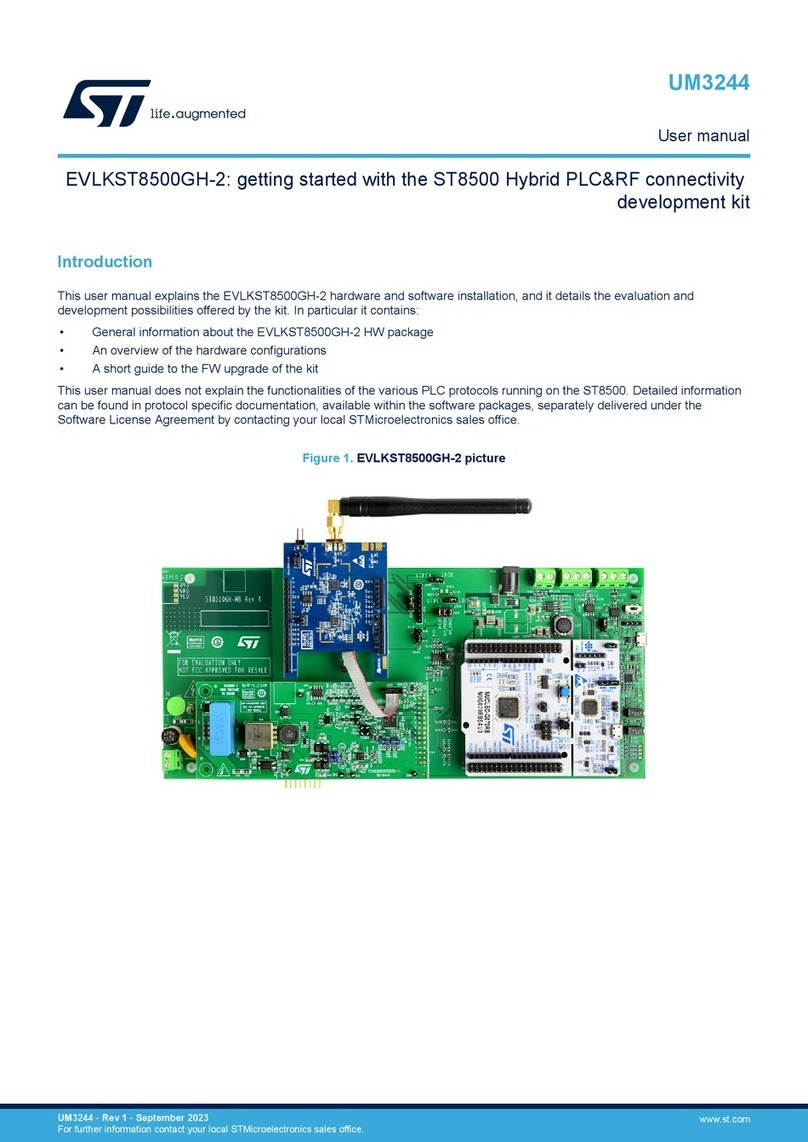

ST EVLKST8500GH-2 User manual

ST

ST X-NUCLEO-IDS01A4 User manual

ST

ST ST10R272L User manual

ST

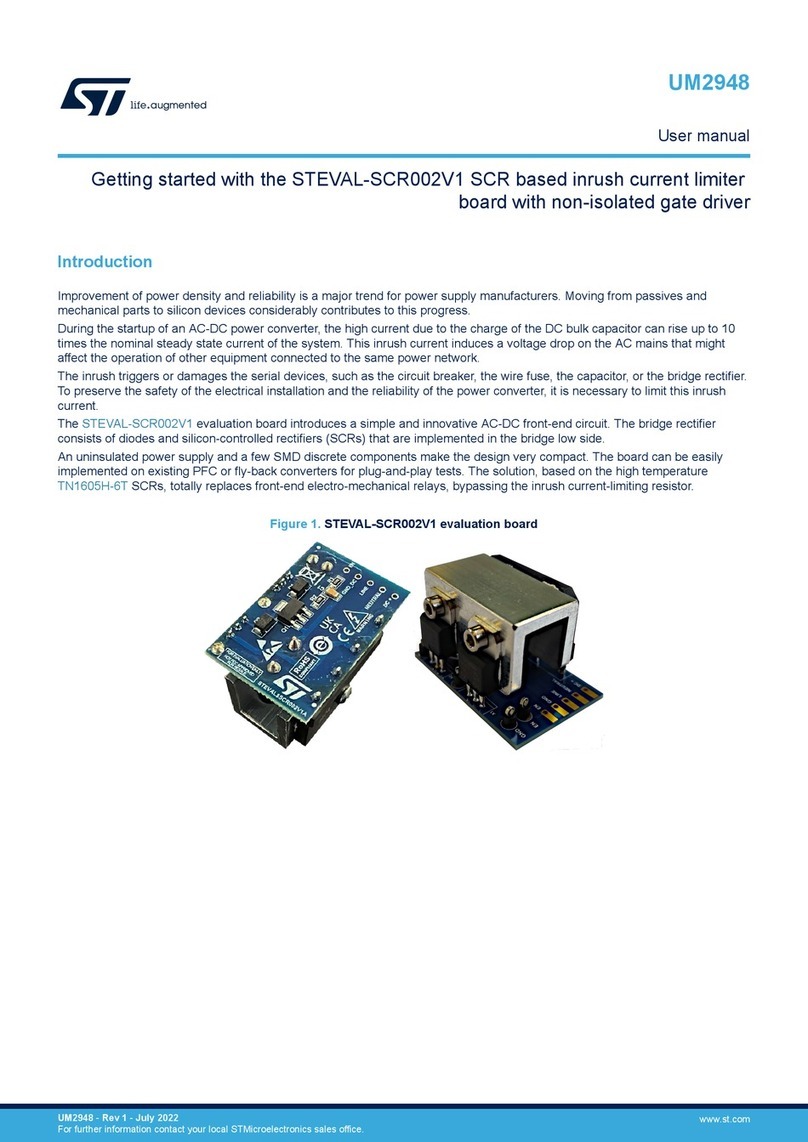

ST STEVAL-SCR002V1 User manual

ST

ST STMPE811 Specification sheet

ST

ST STEVAL-OET005 User manual

ST

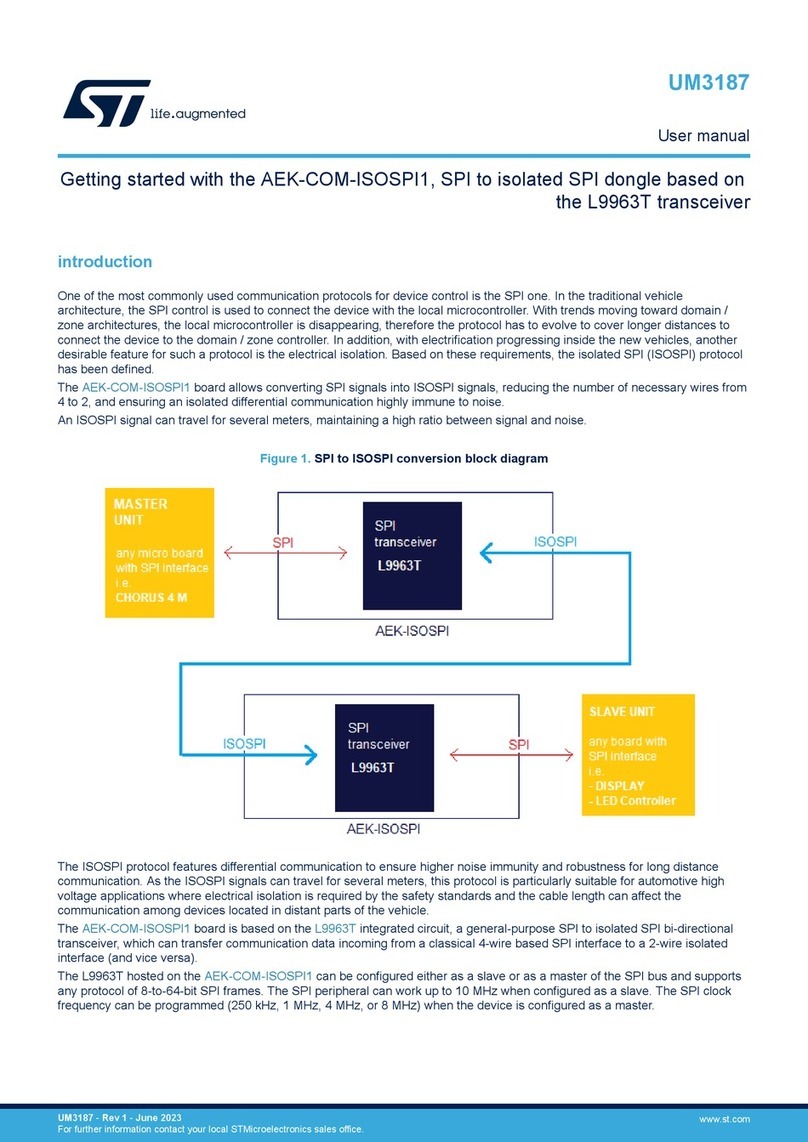

ST AEK-COM-ISOSPI1 User manual

ST

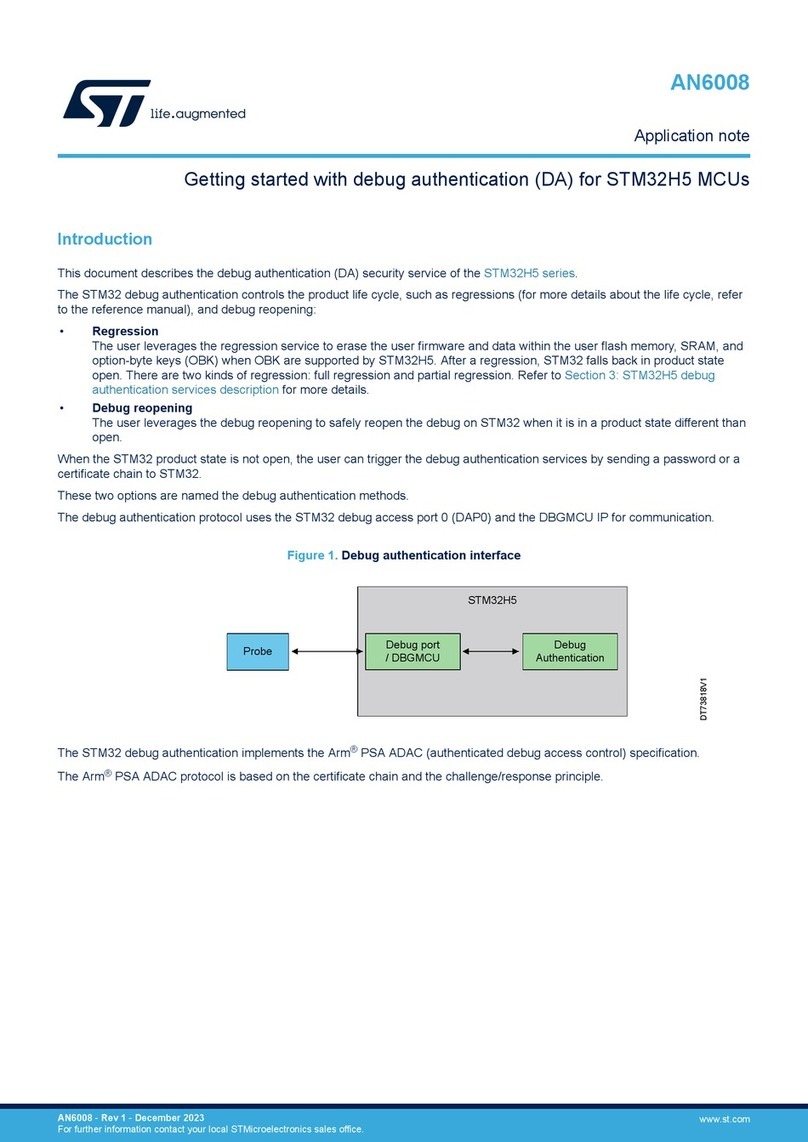

ST STM32H5 User manual

ST

ST STM32CubeF2 User manual

ST

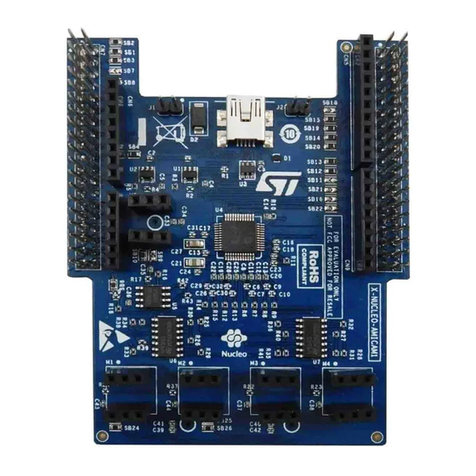

ST X-NUCLEO-AMICAM1 User manual

ST

ST X-NUCLEO-OUT02A1 User manual

ST

ST X-NUCLEO-OUT19A1 User manual

ST

ST CLT01-38SQ7 User manual

ST

ST STEVAL-ST25R3916B User manual

ST

ST X-NUCLEO-53L3A2 User manual

ST

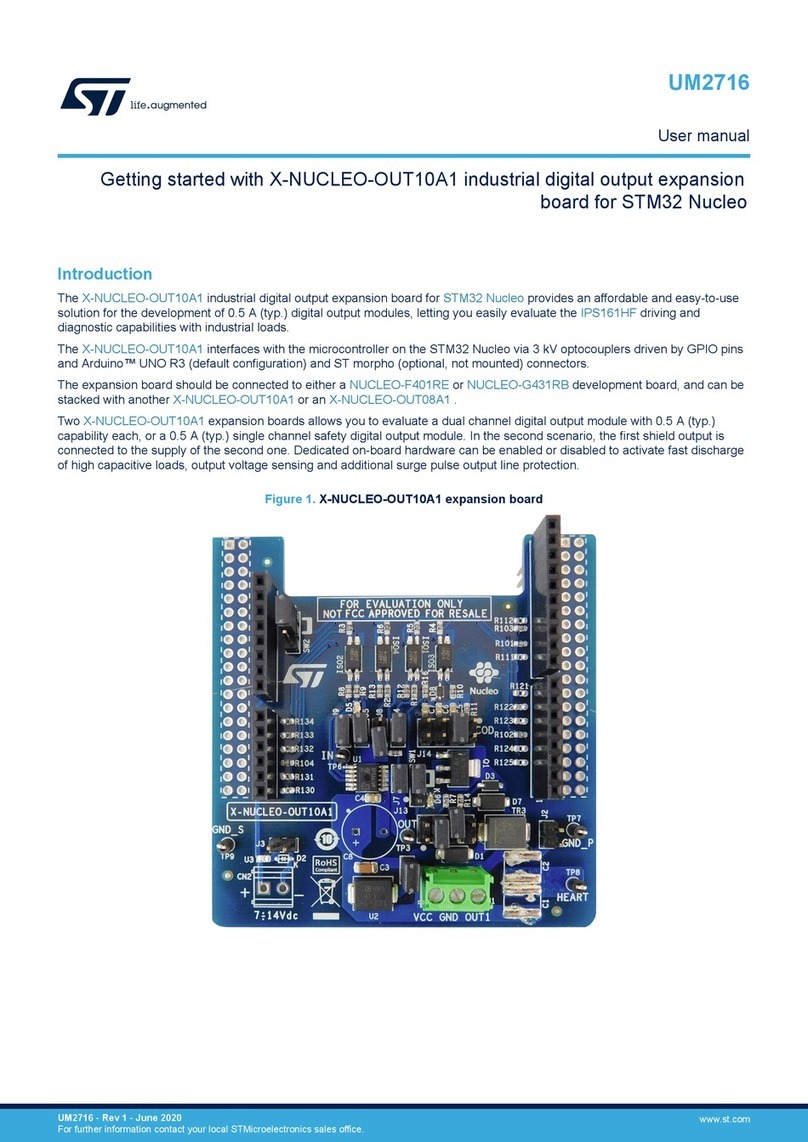

ST X-NUCLEO-OUT10A1 User manual

ST

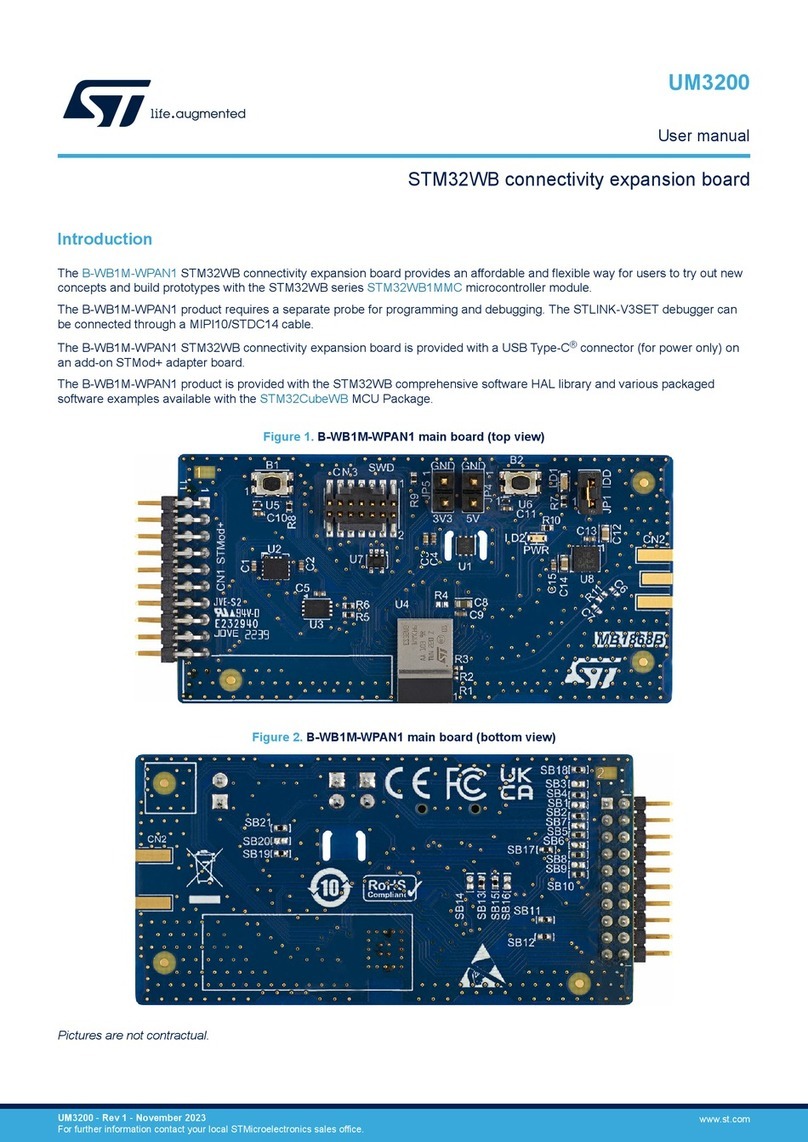

ST B-WB1M-WPAN1 User manual

ST

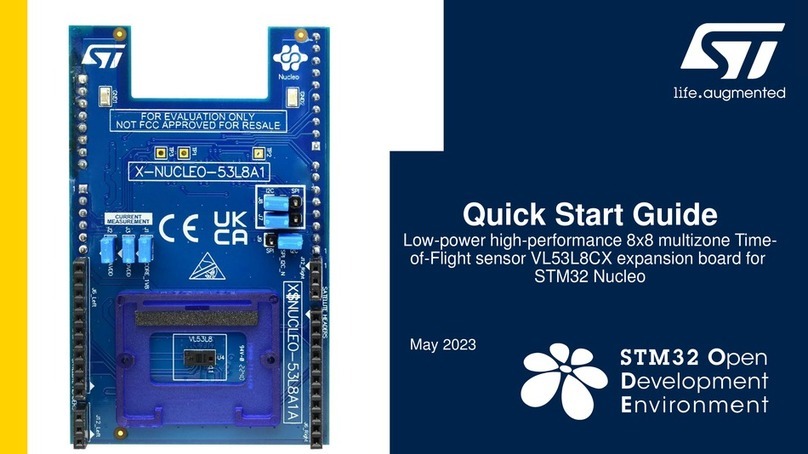

ST X-NUCLEO-53L8A1 User manual

ST

ST STEVAL-TTM001V1 User manual

Popular Computer Hardware manuals by other brands

EMC2

EMC2 VNX Series Hardware Information Guide

Panasonic

Panasonic DV0PM20105 Operation manual

Mitsubishi Electric

Mitsubishi Electric Q81BD-J61BT11 user manual

Gigabyte

Gigabyte B660M DS3H AX DDR4 user manual

Raidon

Raidon iT2300 Quick installation guide

National Instruments

National Instruments PXI-8186 user manual

Intel

Intel AXXRMFBU4 Quick installation user's guide

Kontron

Kontron DIMM-PC/MD product manual

STEINWAY LYNGDORF

STEINWAY LYNGDORF SP-1 installation manual

Advantech

Advantech ASMB-935 Series user manual

Jupiter

Jupiter RAM PACK instructions

Measurement Computing

Measurement Computing CIO-EXP-RTD16 user manual