INSTALLATION OPERATION &

MAINTENANCE DATA SHEET

85 796 07 30 0 2 December 14, 2004

R. STAHL, INC.

9001 Knight Road

Houston, TX 77054

Tel: 800-782-4357 FAX: 713-792-9301

Website: www.rstahl.com

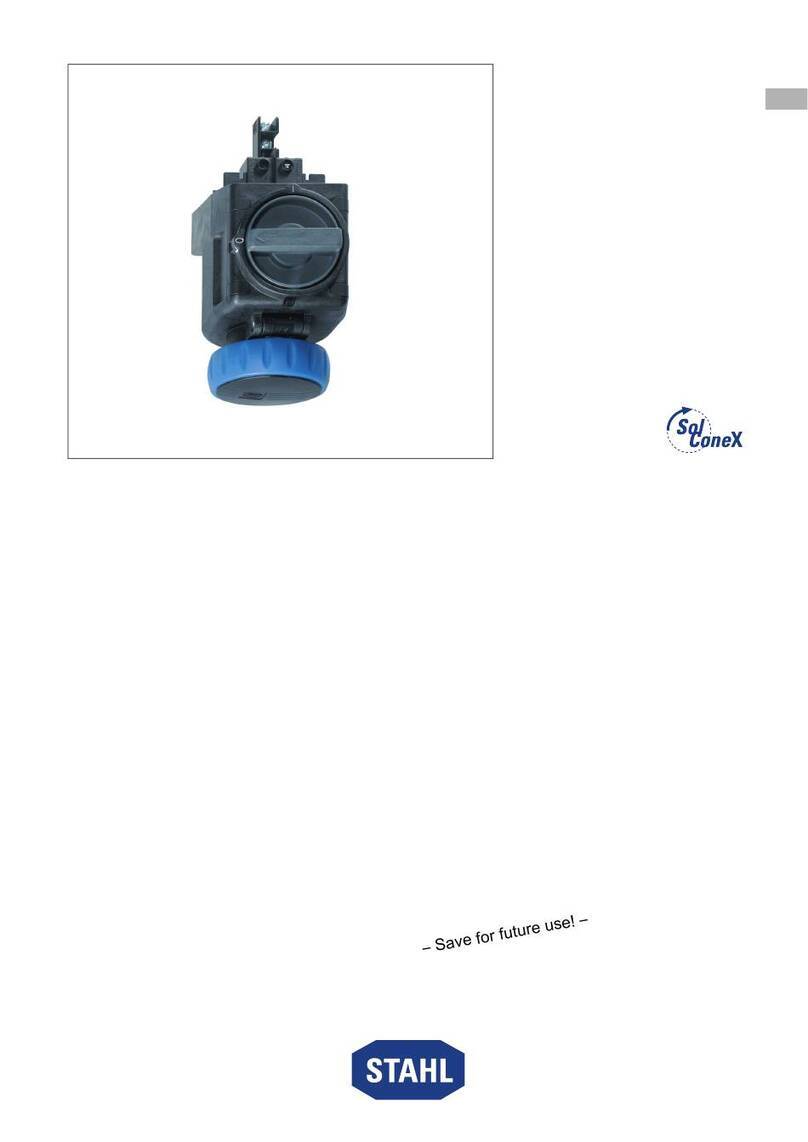

4. Wiring of Plug 8579/22

4.1. Cord Type

Select a flexible cord with copper conductors of the

appropriate insulation, ampacity and 90°C tempera-

ture rating. For installations in the U.S., refer to the

National Electrical Code, Articles 400-4, 400-5A, 400-

5B, 501-11, 502-12 and 503-10. For installation in

Canada refer to CEC section 4 & 18

NOTE: Maximum range for plug terminals is 10-6

AWG. Tighten terminal screws to 26.5 in-lbs

(3 N-m) torque.

4.2. Cord Preparation

Cut the cord cleanly - Do not strip away cord jacket or

conductor insulation at this time.

4.3. Opening the Plug

Referring to Figure 1 above, loosen screws ➀and pull

the plug body ➁out of the shell ➂.Loosen the screw

➃on the locking clamp ➄,insert the screwdriver in

the locking clamp slot, lift the locking clamp out of the

pressure ring ➅and unscrew the pressure ring.

4.4. Insert the Cord

Slide the pressure ring ➅and the washer ➆over

the cord.

4.4.1 Install Cord Grommet

The grommet ➇is a universal onion ring style which

accommodates several cord diameters by removing

(cutting out) the inner undersized diameters. The

grommet should fit snugly on the cord. The grommet

may require lubrication in order to slide over the cord.

Use talcum powder or an equivalent material rated for

use on electrical products. Slide the grommet over the

cord with the cuts toward the shell ➂.

NOTE: If the grommet slides freely over the cord,

there will be insufficient sealing for Class II

and Class III Hazardous Locations.

4.4.2 Slide the shell ➂over the cord.

4.5. Cord Preparation

Dress the cord by removing the outer jacket and fillers

for a length of 3-1/8" (80 mm) and strip the insulation

off of the conductors 5/8" (17 mm) from the end.

4.6. Connection to Terminals

Open the strain relief clamp screws ⑩and flip the

clamp to the side. Attach the leads to the appropriate

terminals 1

1.Terminal markings correspond to recep-

tacle terminal markings.

CAUTION: The Equipment Ground (green wire) is

to be connected to the terminal marked with the Earth

Ground symbol .

4.7. Strain Relief

Adjust the strain relief clamp ⑩to slide over the cord,

if necessary remove the clamp plastic inserts to fit the

plug body ➁.Then tighten the strain relief clamp ⑩.

4.8. Plug Assembly

4.8.1 Insert the plug body ➁into the shell ➂.To align the

plug body ➁with the shell ➂,the keyway on the

inside of the shell must mate with the rib in the plug

body.

4.8.2 Tighten the screws ➀.

4.8.3 Slide the grommet ➇and the gland washer ➆forward

until they shoulder against the shell ➂and tighten the

pressure ring ➅until a good grommet compression is

achieved.

4.8.4 Reinstall the locking clamp ➄and tighten the screw ➃.

4.9. The optional dust cap (P/N 85 798 01 14 0) must be

used for Class II, Divisions 1 & 2, Groups E or F

Hazardous Locations.

WARNING: Users shall observe the labels on the

plug and receptacle with regard to the use of recepta-

cle covers and dust caps.

5. Maintenance

These plugs and receptacles require no maintenance

other than a periodic inspection for damage and prop-

er operation. The surface of the plug pins should be

given a thorough inspection. Any damaged equipment

should be replaced promptly to ensure the electrical

safety and explosion protection of the system.

1

23

4

5

6

7

8

9

103/8

1 5/8

11

keyway

cord

Figure 1.

Note: The nature of these instructions is only informative and does not

cover all of the details, variations or combinations in which this

equipment may be used, its storage, delivery, installation, safe

operation and maintenance.Since conditions of use of the product

are outside of the care, custody and control of the manufacturer,

the purchaser should determine the suitability of the product for

his intended use, and assumes all risk and liability whatsoever in

connection therewith.