Theta Controller

Contents iii

2.8.5 Service.........................................................................33

2.8.5.1 Tool..........................................................................33

2.8.5.1.1 About Tab..........................................................33

2.8.5.1.2 Counters Tab ....................................................33

2.8.5.1.3 CAL Tab............................................................34

2.8.5.2 Controller.................................................................34

2.8.5.3 Controller.................................................................34

2.8.5.3.1 About Tab..........................................................35

2.8.6 Analyze........................................................................35

2.8.6.1 TOOL tab.................................................................35

2.8.6.2 TRACE tab...............................................................36

2.8.6.3 I/O tab......................................................................36

QPM DC Electric Tools ............................................................................38

3.1 Tool Specifications..............................................................38

3.2 Operator Protection ............................................................39

3.2.1 Repetitive Motion.........................................................39

3.2.2 Hearing Protection.......................................................39

3.2.3 Vibration ......................................................................40

3.2.4 Breathing Protection....................................................40

3.3 Tool Installation...................................................................40

3.3.1 Sockets and Adapters..................................................40

3.3.2 Suspension Devices....................................................41

3.3.3 Cable Installation.........................................................41

3.4 QPM Tools..........................................................................41

3.4.1 Display and Multiple Function Button for Hand Held

Tools 41

3.4.2 MFB Mode...................................................................41

3.4.3 Tool Memory................................................................42

3.4.4 Tightening Cycle Counters ..........................................42

3.5 Tool Operation....................................................................43

3.5.1 Directional Control.......................................................43

3.5.2 Torque Reaction Devices ............................................43

3.5.3 Tool Temperature........................................................44

3.5.4 Tool Status Lights........................................................44

3.5.5 Tool Audible Device.....................................................44

3.5.6 Setting Torque, Angle and Other Operating

Parameters................................................................................44

3.6 Special Application Tools....................................................44

3.6.1 Exposed Gear Socket Tools........................................44

3.6.2 Tubenut Nutrunners.....................................................45

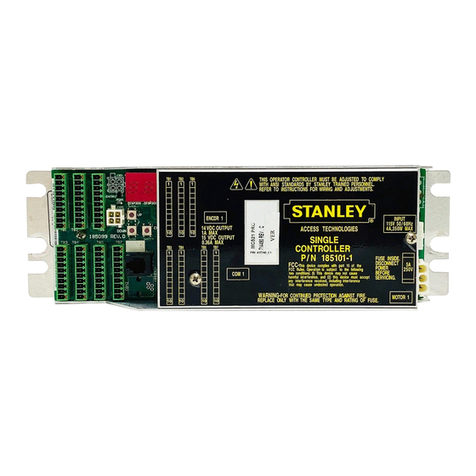

Theta Controller Connections...................................................................46

4.1 Theta Controller Connections.............................................46

4.1.1 Theta Controller Power Cord.......................................46

4.1.2 Theta Controller Tool Connector .................................46

4.1.3 Theta Controller Serial Connector...............................47

4.1.4 Theta Controller Input and Output Connector..............47

4.2 Assignable Input/Output Functions.....................................50

4.2.1 Input Descriptions........................................................51