© 2002, THE STANLEY WORKS. ALL RIGHTS RESERVED. 203959

Rev. F, 10/2/02

1 of 23

Stanley Access Technologies

Quick-Reference Guide TABLE OF CONTENTS

1. PURPOSE ....................................................................................................................................................2

1.1 Discussion................................................................................................................................................2

1.2 Applicability ............................................................................................................................................2

1.3 Features and Functions ............................................................................................................................2

2. PRECAUTIONS ..........................................................................................................................................4

3. WIRING INSTRUCTIONS.........................................................................................................................4

3.1 Evaluating Power Requirements..............................................................................................................4

3.2 Connecting Main Power Wiring..............................................................................................................4

3.3 Connecting Breakout Status Signal Wiring (Magic-Swing Operators)...................................................5

3.4 Connecting Breakout Status Signal Wiring (Magic-Force Operators)....................................................7

3.5 Wiring the Operator Switch Module (Magic-Force Operators)...............................................................9

3.6 Wiring the Operator for Required Handing (Magic-Force Operators)..................................................10

3.7 Wiring the “ON/OFF/HOLD OPEN” Switch........................................................................................10

3.8 Wiring the Door Activation or Safety Device .......................................................................................11

3.9 Wiring Sentrex3......................................................................................................................................11

3.10 Wiring the Counter ................................................................................................................................11

4. TUNE-IN INSTRUCTIONS......................................................................................................................11

4.1 Initial Tune-In Settings..........................................................................................................................11

4.2 Final Tune-In Adjustments....................................................................................................................12

ATTACHMENTS

Attachment 1, Breakout Status Wiring...............................................................................................................14

Attachment 2, Magic-Force Operator Wiring—Dual Operators with Dual-Adjustment Closing Speed

Controls and Switch Modules........................................................................................................................15

Attachment 3, Magic-Force Operator Wiring—Dual Operators with Dual-Adjustment Closing Speed

Controls, Power Close Modules, and Switch Modules..................................................................................16

Attachment 4, Magic-Swing System Wiring—Main Power, Motor(s), and Encoder(s)....................................17

Attachment 5, Signal Wiring— HDLE/FE Control Box with Carpets, Pushplate, Operate Sensor,

or Safety Sensor ..............................................................................................................................................18

Attachment 6, Wiring Diagram— HDLE/FE Control Box with Bifold Doors ..................................................19

Attachment 7, Wiring Diagram—HDLE/FE Control Box with Sentrex3..........................................................20

Attachment 8, DIP Switch S2 Mode Settings.....................................................................................................21

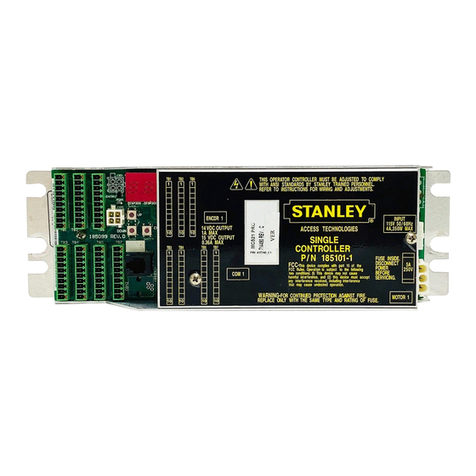

Attachment 9, HDLE/FE Control Box................................................................................................................23