Table of Contents

QB Expert Alpha Controller

IV

4.2.4 Manage Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.3 Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.3.1 Parameter and Data Retrieval . . . . . . . . . . . . . . . . . . . . . . 91

4.4 Trace Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4.4.1 Analyzing Traces . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.4.2 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.5 Icons and Security . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5 QPM DC Electric Tools . . . . . . . . . . . . . . . . .104

5.1 Tool Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 104

5.1.1 Operator Protection . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1.2 Repetitive Motion . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1.3 Hearing Protection . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1.4 Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.1.5 Breathing Protection . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.1.6 Tool Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.1.7 Sockets and Adapters . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.1.8 Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.2 QPM Tool Controls and Operation . . . . . . . . . . . . . . . . . . 108

5.2.1 Start Trigger Switch . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.2.2 Tool Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.2.3 Display and Multiple Function Button . . . . . . . . . . . . . . . . . 109

5.2.4 Tool Status Lights . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.2.5 MFB Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.2.6 Worklights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.7 Program Selection . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.8 Directional Control . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.9 Tool Temperature . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.10 Setting Torque, Angle, and Other Operating Parameter . . . . . . . . . 112

5.2.11 Assembly (Forward) Operation . . . . . . . . . . . . . . . . . . . . . 112

5.2.12 Disassembly (Reverse) Operation . . . . . . . . . . . . . . . . . 112

5.3 Special Application Tools . . . . . . . . . . . . . . . . . . . . . . .112

5.3.1 Exposed Gear Socket Tools . . . . . . . . . . . . . . . . . . . . . 112

5.3.2 Tubenut Nutrunners . . . . . . . . . . . . . . . . . . . . . . . . . 113

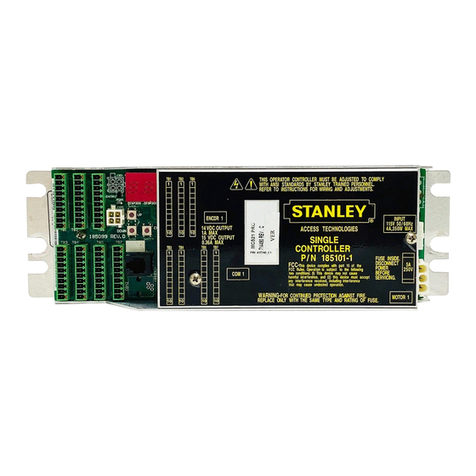

6 Alpha Controller Connections . . . . . . . . . . . . . . 118