Only approaching the cutting disc running against the

workpiece when the disc reaches its maximum speed.

After starting wait at least 4 seconds until the disk rotate at

rated speed.

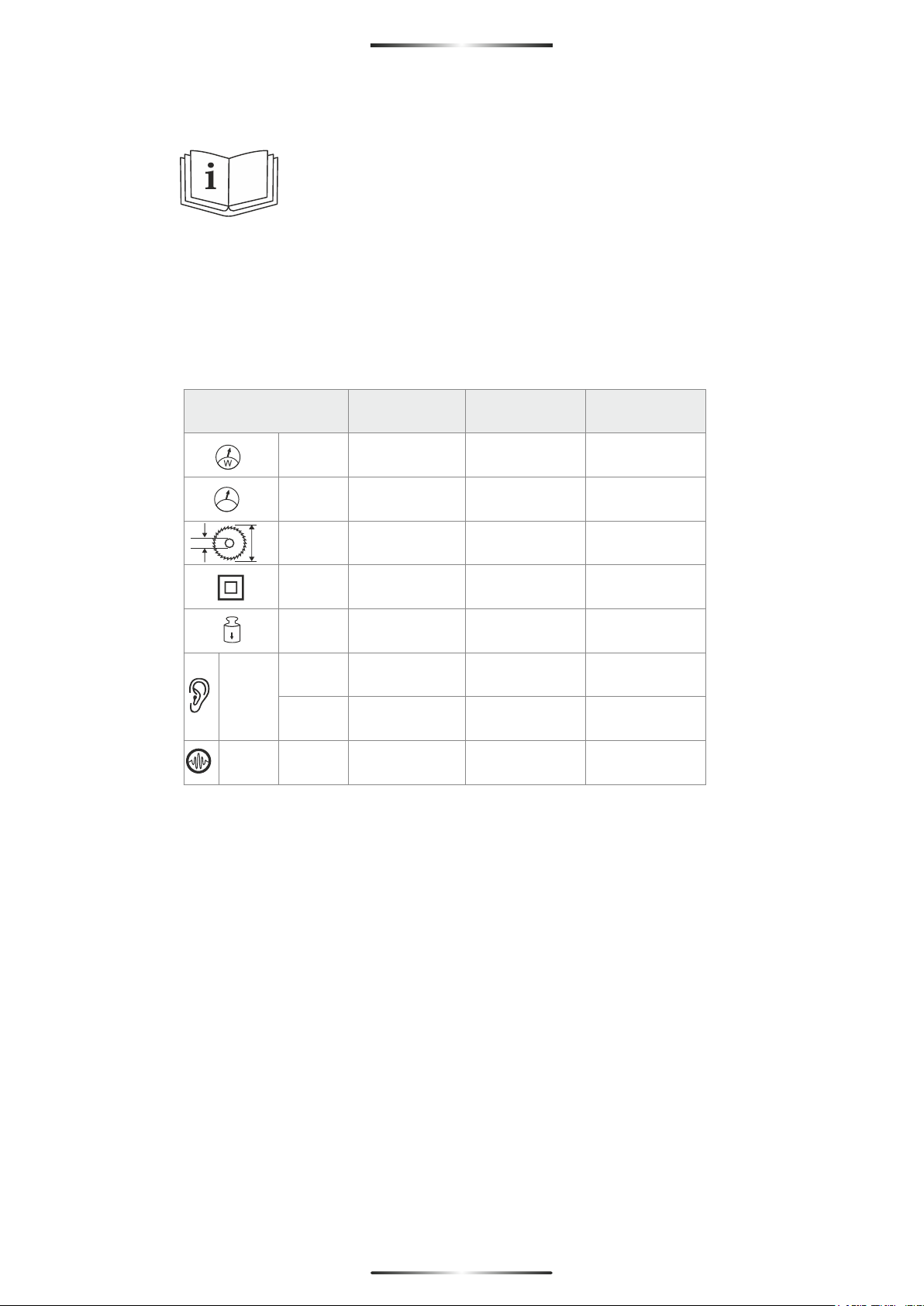

Always firmly clamp the workpiece. Do not cut

workpieces that are too small to clamp. Otherwise, the

clearance of your hand to the rotating cutting disc is too

small.

If the cutting disc becomes jammed, switch the

machine off and wait until the cutting disc comes to a

complete stop. Never attempt to remove a still running

cutting disc from the cut, otherwise there is danger of

kickback. Determine and correct the cause for the

jamming.

After switching off, do not stop the cutting disc by

applying lateral pressure to it. The cutting disc can

become damaged, break or lead to kickback.

Do not force the cutting disc into the workpiece and do

not apply too much pressure when using the power

tool. Particularly avoid jamming or wedging the cutting

disc when working corners or sharp edges. When the

cutting disc is damaged due to abuse, cracks can form that

can lead to breakage without prior warning.

Wear a work apron. Pay attention that other persons are

not put at risk from sparking. Remove flammable

materials in close vicinity. Sparking occurs when cutting

metal.

Use the cut off grinder only for cutting materials

mentioned under “Intended Use”. Otherwise, the cut off

grinder can be subject to overload.

Do not use damaged, out-of-centre or vibrating cutting

discs. Damaged cutting discs cause increased friction,

binding of the cutting disc and kickback.

Always use cutting discs with correct size and shape

(diamond versus round) of arbor holes. Cutting discs

that do not match the mounting hardware of the cut off

grinder will run eccentrically, causing loss of control.

Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent kickback

and loss of control over the power tool.

Observe the operating instructions of the cut-off wheel

manufacturer for assembly and use of the cut-off

wheel. Cut-off wheels that do not fit can lead to injury as well

as to jamming, breaking or kickback.

Do not use accessories which are not specifically

designed and recommended by the tool manufacturer.

Just because the accessory can be attached to your power

tool, it does not assure safe operation.

Do not touch the cutting disc after working before it has

cooled. The cutting disc becomes very hot while working.

The machine TV509 / TV509B / TV509C is intended for stationary

use with cutting abrasive discs to perform lengthways and

crossways straight cuts or mitre cuts to 45° in metal materials

without the use of water.

This manual is consistent with the date of manufacture of your

machine, you will find information on the technical data of the

machine acquired manual check for updates of our machines on

the website: www.grupostayer.com

1. Contents page

2.Specific safety instructions......................................20

3.Instructions for use....................................................21

3.1 Placement Tool.............................................................21

3.2 Assembly......................................................................21

3.3 Illustrated description............................................21

4.Operating instructions..............................................21

4.1 Placement and testing..........................................21

4.2 Tool change..........................................................22

4.3 Operation adjustment...........................................23

4.4 Limitations on the size of the workpiece.................23

4.5 General instructions for use..................................24

5.Maintenance and service instructions.....................24

5.1 Cleaning...............................................................24

6.2 Repair service.......................................................24

5.3 Warranty...............................................................24

5.4 Disposal and recycling..........................................24

6.Regulations................................................................24

6.1 Technical Data......................................................24

6.2 EU declaration of conformity.................................25

2. Specific safety instructions

Never stand on the power tool. Serious injuries could

occur when the power tool tips over or when accidentally

coming into contact with the cutting disc.

Always use the blade guard. A blade guard protects the

user against broken off parts of the cutting disc and against

accidental touching of the cutting disc.

Make sure that the guard operates properly and that it

can move freely. Never lock the guard in place when

opened.

Use the power tool only for dry cutting. Water

penetrating into a power tool increases the risk of an electric

shock.

Keep the mains cable away from rotating application

tools. The mains cable can be cut through or get caught.

Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery causing loss of control.

Never remove cutting remainders, metal chips, etc.

from the cutting area while the machine is running.

Always guide the tool arm back to the neutral position first

and then switch the machine off.

Guide the cutting disc against the workpiece only when

the machine is switched on. Otherwise, there is danger of

kickback, when the cutting disc becomes wedged in the

workpiece.

ENGLISH

7

7