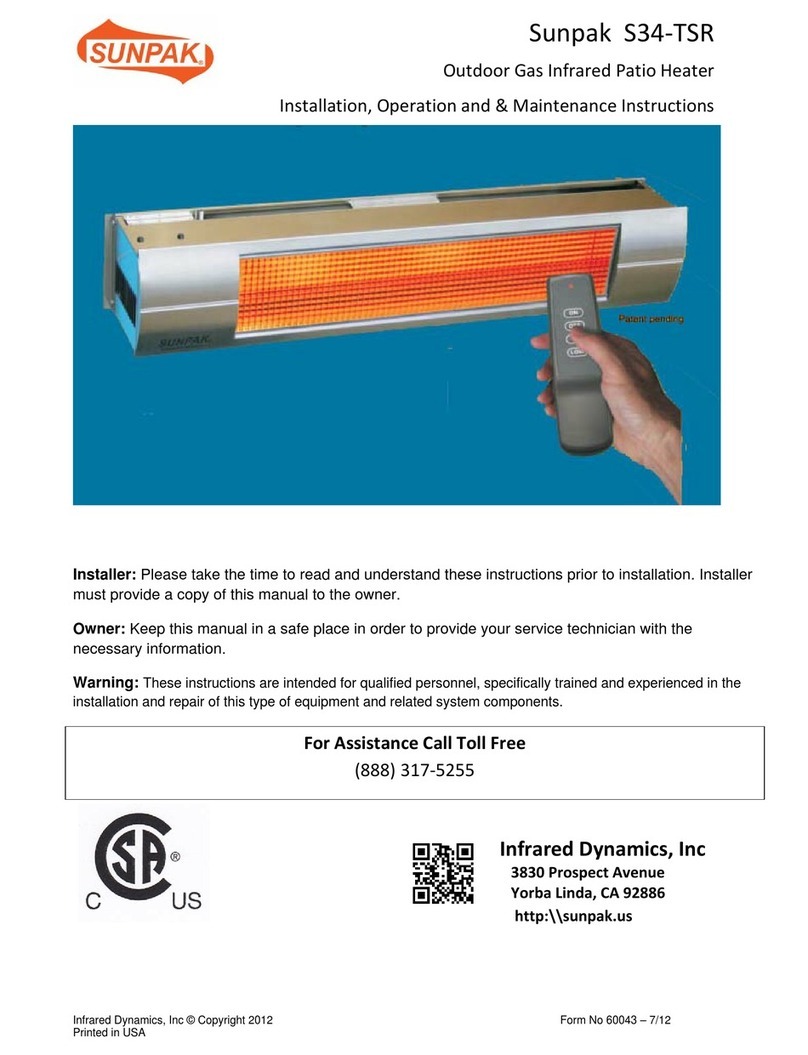

Sunpak® Infrared Heaters

7

Installation/Service Instruction

Receiving Equipment

On receipt of equipment it is suggested that a visual

inspection be made for external damage to the carton. If

the carton is damaged, a note should be made on the

Bill of Lading when signing for the equipment. Remove

the heater from the carton. If there is damage, report the

damage to the carrier immediately.

INSTALLATION INSTRUCTIONS

Important Notice

These instructions are intended for qualified personnel,

specifically trained and experienced in the installation of

this type of equipment and related system components.

Some states or provinces require installation and

service personnel to be licensed. If your state or

province is such, be sure your contractor bears the

appropriate license. Persons not qualified shall not

attempt to fix this equipment nor attempt repairs

according to these instructions.

WARNING

Asphyxia, Explosion or Fire

Improper installation, adjustment, alteration,

service or maintenance may create a hazard

resulting in asphyxiation, explosion or fire, or

damage to the equipment.

Code Requirements

Installation must be in accordance with local codes, or in

the absence of local codes, with the latest edition of the

National Fuel Gas Code, ANSI Z224 and National

Electrical Code ANSI/NFPA 70, and for Canada, the

latest edition of CAN/CGA-B149.1 and B149.2 and

Canadian Electrical Code, CSA C22.1 Part 1 and Part 2.

•Heaters to be installed in Aircraft hangars must be

installed in accordance with American National

Standards for Aircraft Hangars, ANSI/NFPA

No. 409.

•Heaters to be installed in Public Garages must be

installed in accordance with NFPA No. 88A,

Standards for Parking Structures.

•Heaters must be installed so that minimum

clearances marked on the heaters will be

maintained from vehicles parked below the heater.

•Each heater must be electrically grounded in

accordance with the National Electrical Code,

ANSI/NFPA 70, when an external electrical source

is utilized. In Canada, the CSA Canadian

Electrical Code, C22.1 Part 1 applies.

Gas Supply

The gas inlet supply pressure and manifold pressure required

for each heater are listed below. For gas supply line

pressures in excess of ½ psig, consult with your

representative or the factory.

Gas Inlet Pressure Nat Gas Propane

Maximum Pressure ½ psig ½ psig

Minimum Pressure 6” W.C. 11” W.C.

Manifold Pressure 5” W.C. 10” W.C.

It is important that the gas piping system be adequately sized

for all the gas appliances it serves.

Clearances

Each heater must be installed such that the following

“Minimum Clearance to Combustible Materials’ are

maintained.

Combustible materials include wood, compressed paper,

plant fibers, and plastic, Plexiglas or other materials capable

of being ignited and burned. Such materials shall be

considered combustible even though flame-proofed, fire

retardant treated or plastered. Additional clearance may be

required for glass, painted surfaces, vinyl siding or other

materials which may be damaged by radiant or convection

heat.

Adequate space around each heater is required even when

the materials surrounding the heater are non- combustible to

provide adequate combustion air and ventilation of exhaust

gases. Heaters should never be located in a ceiling recess or

soffit.

The stated clearance to combustible materials represents a

surface temperature of 90ºF (32ºC) above room temperature.

Building materials with a low heat tolerance (such as plastic,

vinyl siding, canvas, tri-ply, etc.) may be subject to

degradation at lower temperatures. It is the installer’s

responsibility to assure that adjacent materials are not

subject to degradation.

In locations used for storage of combustible materials, signs

shall be posted to specify the maximum permissible stacking

height to maintain required clearances from the heater to

combustible materials.

OPTIONAL MOUNTING KIT (#12006): Optional Mounting Kit

is available from your heater supplier. Whether the mounting

kit is used or not, minimum clearance from combustibles

must be observed as follows:

WARNING: The clearances shown below are also applicable

to vehicles parked below heaters.

Input Side Rea

Ceiling Below Mtg.

Model BTUH In In In In

ngle

S34 34,000 24” 17” 13” 48” HORIZ

S34 34,000 24” 8” 18” 48” 30º MAX