HAWK Ceiling

2We reserve the right to alter specifications. 20080315 www.swegon.com

Technical description

Design

The square, perforated supply air diffuser consists of a

diffuser backing box and a diffuser face. The diffuser face

has perforations designed for managing high airflows.

The diffuser face is hung on hinges on one side and

secured by springs on the opposite side. This Quick Access

fastening system makes it simpler and quicker to open

and close the diffuser face for installation, commissioning

and cleaning. The air diffuser is also available in a low

version for installation in ceiling void where low instal-

lation height is required. The air diffuser is then supplied

without any branch.

Materials and surface treatment

The backing box and diffuser face are made of sheet

steel. The connection branch is made of galvanized sheet

steel. The interior and exterior surfaces of the air diffu-

sers are painted in our standard colour: RAL 9010. The

air diffusers are also available in optional colours: RAL

7037 Dusty grey, RAL 9006 white aluminium, RAL 9005

jet black, RAL 9007 grey aluminium and RAL 9003 signal

white (NCS 0500).

Accessories

Commissioning box:

ALS. Made of galvanized sheet steel. Contains removable

commissioning damper, fixed measurement tappings and

sound absorbing material with reinforced surface layer, to

Fire Resistance Class B-s1,d0 according to EN ISO 11925-2.

The air diffuser is also available in a low version if the

height in the ceiling void is restricted. The commissioning

box is then supplied without outlet branch.

The commissioning box is available with 1 or 2 differences

in dimension between the inlet and outlet.

Frame:

SAR K. For aesthetic installation of a lowered diffuser.

Planning

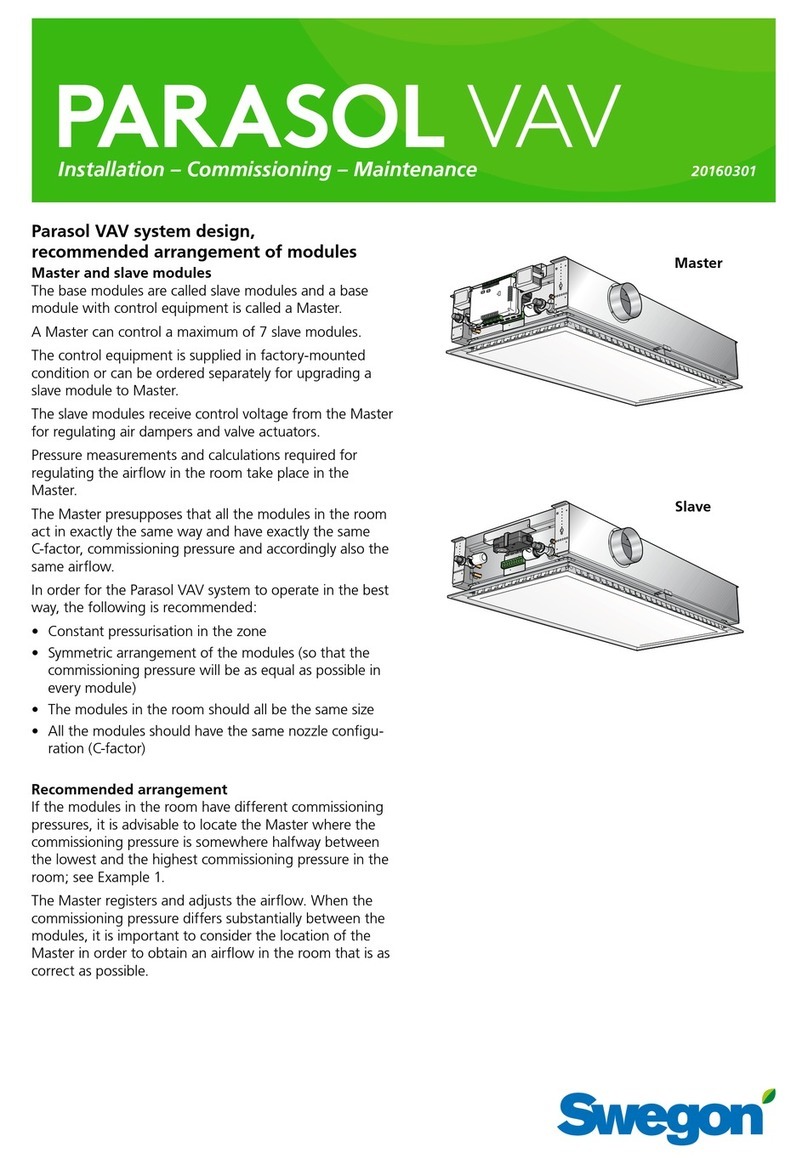

The HAWK Ceiling is available with square dimensions

of 595 x 595 mm in all connection sizes. This makes the

HAWK Ceiling very easy to install in suspended modular

ceilings with insertion dimensions for 600 x 600 mm

modules. Position the whole air diffuser on the surface

of the T-bar framework and then secure it to the duct

system. The HAWK Ceiling is also available in a low

version for installation in ceiling void where its installation

height must be minimized. See Figures 1 and 2.

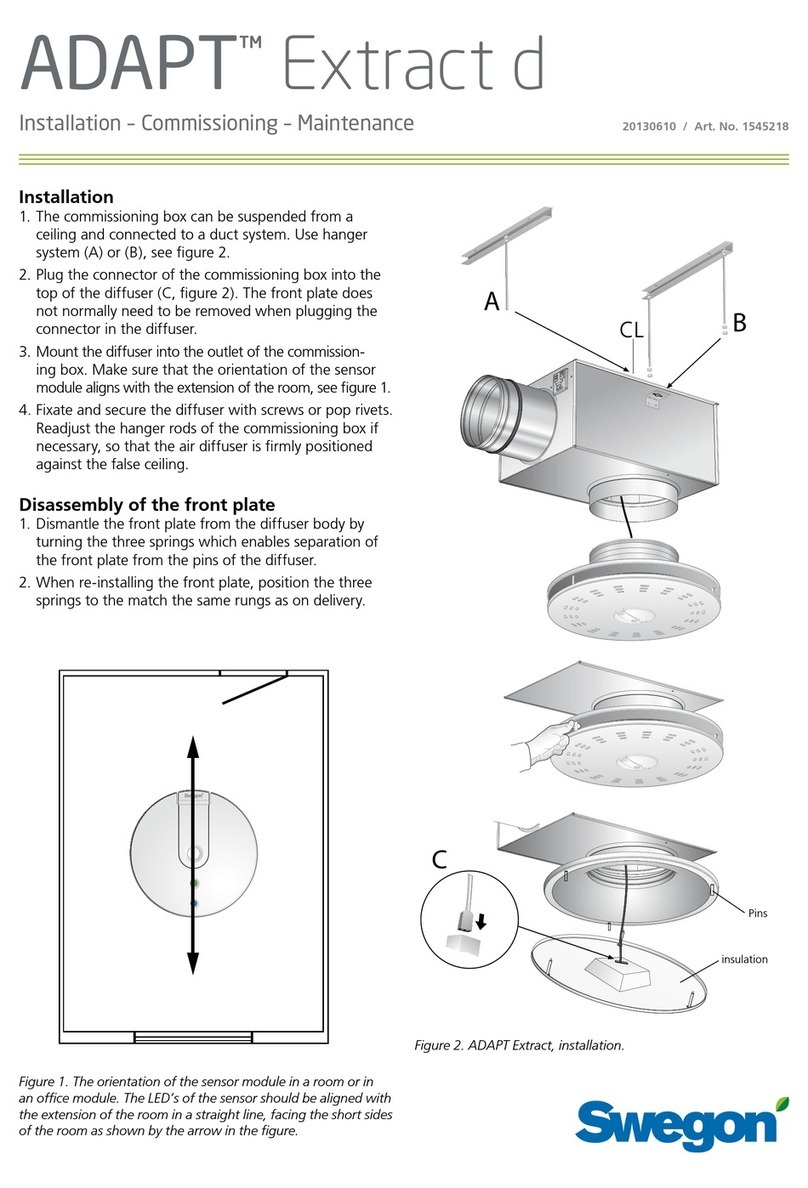

Installation

To dismantle the face (see Figure 2) prior to installing the

air diffuser, insert a thin object, such as a Quick Access

card or similar card, between the air diffuser face and

backing box to release the springs. Then slide the card

from the centre outward toward the corners. The inlet

spigot of the diffuser backing box can be secured to the

connecting ducting by means of self-tapping screws or

blind rivets.

For flush-mounting in fixed ceiling constructions, secure

the air diffuser by means of screws into place in the

framework through either the sides or top of the diffuser

backing box. The face and backing box in the version

for low installation height must be centred and jointed

together using the locking strip supplied. Secure the air

diffuser in the correct position by means of self-tapping-

screws to the underside of commissioning box.

Position these directly down in the T-bar framework, and

then secure them to the duct system or to the commissio-

ning box. If an ALS commissioning box is used, it must be

secured to the building structure by means of hangers or

mounting brackets. The distance between the air diffuser

and the commissioning box can be increased by as much

as 500 mm with an ordinary circular duct without having

to lengthen the measuring tubes and damper adjustment

cords. See Figures 1, 2 and 3.

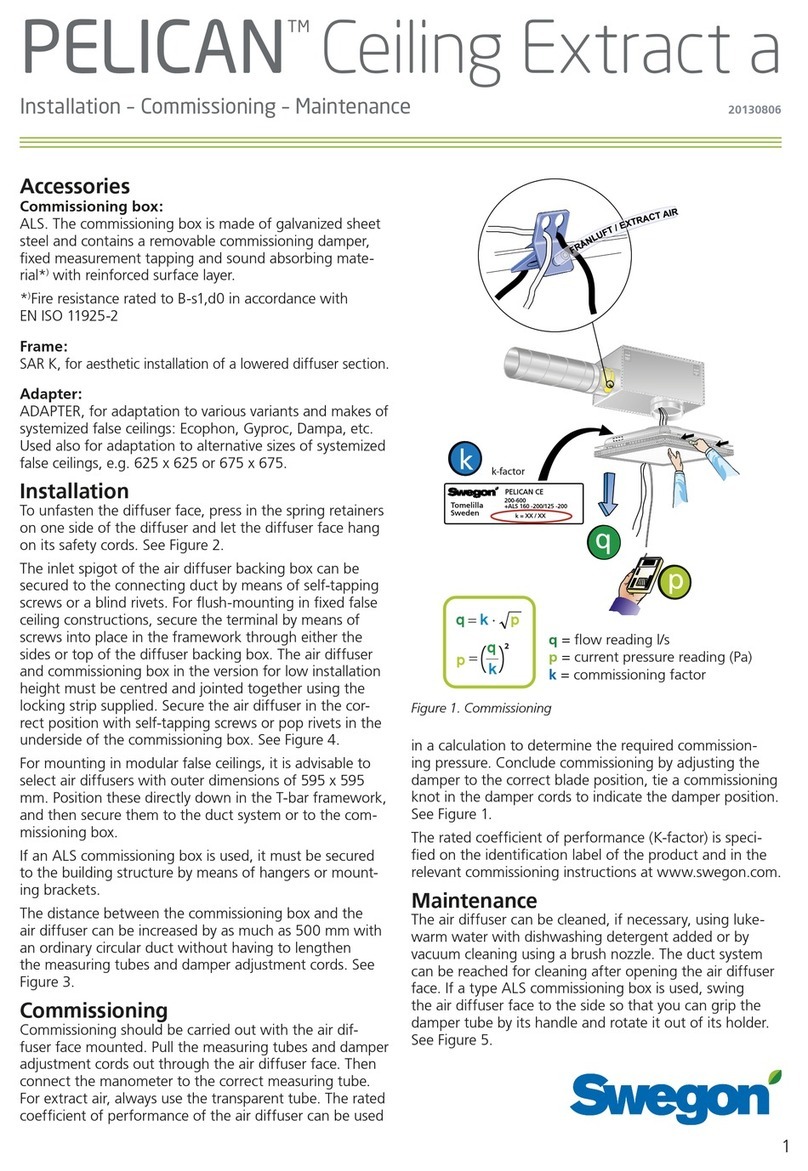

Commissioning

Commissioning must be carried out with the diffuser

face mounted. Pull out the measuring tubes and damper

adjustment cords through the diffuser face perforations.

Connect a manometer to the measuring tubes. The desi-

red commissioning pressure can be calculated by applying

the rated coefficient of performance of the air diffuser.

Set the damper blade in the correct position and tie the

damper adjustment cords in a commissioning knot to

indicate the damper position.

The rated coefficient of performance of the air diffuser

(K-factor) is specified on the identification label and the

relevant commissioning instructions are also available at

www.swegon.com.

Maintenance

The air diffuser can be cleaned, if necessary, using luke-

warm water with dishwashing detergent added. The duct

system can be accessed after opening the diffuser face.

If an ALS commissioning box is used, pull the distributor

plate aside and then twist the damper unit from of its

mounting.

Environment

The Declaration of construction materials is available at

www.swegon.com.