2

Swegon reserves the right to alter specifications. 20100816 www.swegon.com

WISE

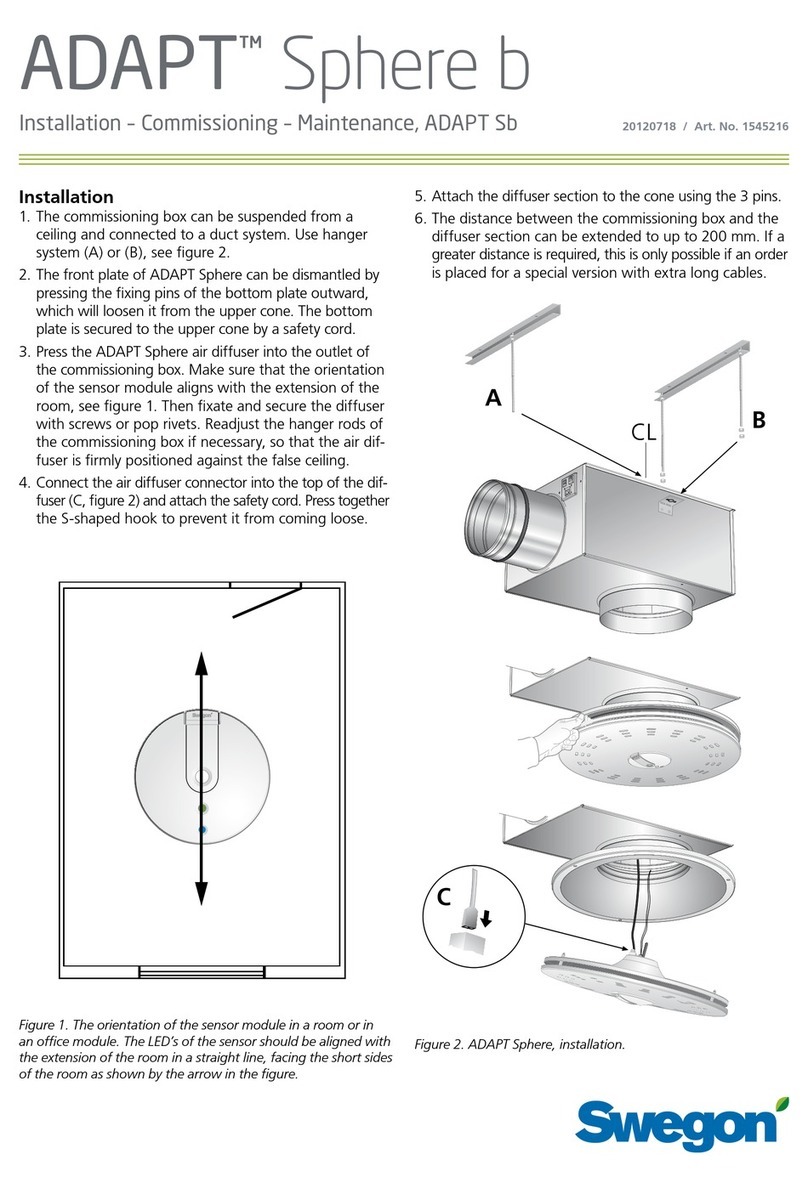

Figure 3. Connection of slave air diffusers and accessories. For

the ADAPT Ea, one slave air diffuser is normally connected to the

Junction box of the Master air diffuser.

1. ADAPT Master air diffuser (not shown in picture)

2. ADAPT Ea

3. CONNECT Adapt, wiring terminal for the Master air diffuser

4. 230-24 V AC Transformer

5. 5 m long LINK Adapt (RJ45 cable)

10. Connection to main control system (Modbus RTU)

11. SPLIT Link

24 V

Modbus

Figure 5. Commissioning.

Maintenance

The exterior surface of the ADAPT air diffusers can be

cleaned whenever necessary using lukewarm water with

dishwashing detergent added. Normally the best method

of cleaning is vacuuming with a brush nozzle.

The duct system is accessible through the air diffuser and

the commissioning box.

Electrical connections

All the electrical connections are wired to the CONNECT

Adapt junction box, which belongs to the Master air dif-

fuser. The slave air diffuser is connected by means of the

LINK Adapt (RJ45) cable (included in the supply) to its

respective slave contacts. If more than 2 slave air diffusers

are installed, a SPLIT Link should be used to further con-

nect to the last slave air diffuser. See Figure 4. The maximal

permissible length of the LINK Adapt from the connection

box to the last air diffuser is 15 m if the SPLIT Link is used.

If ADAPT is to be connected up to Modbus communica-

tion, this should be done by means of the LINK Modbus

(RJ12) cable. All cables and contacts are different so that

they will not be confused or incorrectly connected.

Electrical data

ADAPT is supplied with power via the junction box. See the

wiring diagram. It is important that cables with appropri-

ate cross-sectional area, transformers of correct size and

power supply cables of correct length are selected accord-

ing to the specifications in the sizing documents available

at www.swegon.com.

Supply voltage 24 V AC ±10 %

Max. power consumption 3 VA

Cable rating 0,6 A

Ambient temperature: 0 °C - +50 °C

Commissioning

All the ADAPT Air terminals are supplied preset to the so-

called commissioning mode, which means that the air diffuser

is controlled by force to the max. airflow setting. More infor-

mation about the commissioning process itself can be read in

the Project Manual for the Wise system and in the instructions

for TUNE Adapt. When the ADAPT air diffuser is in com-

missioning mode, the light-emitting diode shines orange.

• Steady green LED: Normal operation, the air diffuser is

operating normally.

• Flashing green LED: The air diffuser has just been energi-

sed and calibration is in progress.

• Steady red LED: The voltage (24V AC) is too low

• Flashing red LED: Internal sensor error

• Steady orange LED: The commissioning mode, max.

airflow

• Flashing orange LED: Other commissioning modes and

all the forced control situations of the feed-back control

system.

2

3

1

Figure 4. Air diffuser connections

1. Connection for LINK Adapt cable (RJ45)

2. Connection for the LINK Modbus cable (RJ12). Only the master

air diffuser should be connected.

3. Direct 24 V connection if a junction box is not used and the air

diffuser will be completely “stand alone”.

20

Master

21

Slave

22

Slave

23

Modbus

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

2

4

3

55

22

10

11

5

- + C