Operating Instructions

www.snopakebrands.com

10

Essential Information

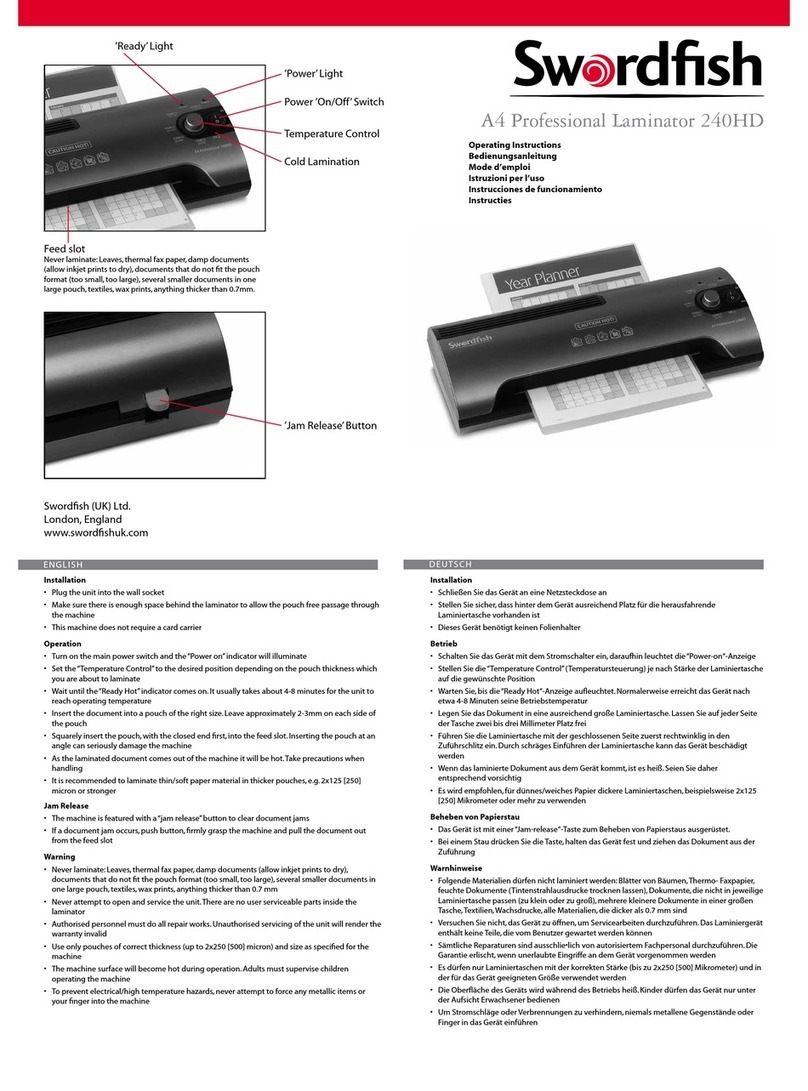

Cold Lamination

• Never insert a pouch until the previous lamination has been removed from the machine. Failure to do so could cause a jam.

• The maximum capacity of this machine (pouch + contents) is 1.0mm.

• Should a miss-feed or jam occur, press “REV” to eject the pouch.

The majority of lamination is done using pouches that are coated with adhesive that melts at high temperature. However,

pouches coated with pressure-activated adhesive - so-called cold lamination pouches - are also available.

If you wish to use cold lamination pouches, turn on the red switch at the back of machine, press ”PWR” to display the

control panel and then press ”SET” repeatedly until “COL” shows. The machine will then go into cold laminating mode.

Cold Laminating can now begin.

If the machine is still warm from previous hot lamination and you wish to now use cold lamination pouches, press ”SET”

repeatedly until “COL” shows. “Cooling”will flash in the control panel while the rollers cool down. “Cooling” will stop

flashing and “Ready” will appear when the desired temperature has been reached. Cold Laminating can now begin.

Maintenance

We recommend that you regularly inspect the rollers for signs of pouch adhesive on the rollers and remove it with a soft

cloth and alcohol (surgical spirit, rubbing alcohol or methylated spirit) when necessary. Do not use white spirit, petrol or

any other solvents as they could damage the silicone rollers. Do not use sharp or abrasive tools when cleaning the rollers.

The inner faces of lamination pouches are coated with an adhesive that becomes molten at high temperatures. When

a pouch is completely filled, this adhesive will usually be absorbed by the paper in the pouch. However, some adhesive

may be squeezed out of the pouch and onto the rollers. If a pouch is not completely filled, a great deal of adhesive can be

squeezed out onto the rollers.

IMPORTANT

Sticky rollers can cause pouches to jam, so it is important to keep them clean.

To access the rollers, disconnect the machine from the electricity supply, allow it too cool, and then remove the top cover

which is retained by two screws at the back. Use caution if the machine has been used recently – the top cover, the rollers

and adjacent components may still be hot!

If you wish to clean the rollers while they are turning, first press ”SET” repeatedly until “COL” shows so that the machine

goes into “cold lamination”mode and allow it to cool down.

Remove the top cover only. Do not further dismantle the machine – risk of electric shock! Use extreme caution – take care

that hair, clothing, jewellery, etc. does not become trapped by the rollers.

Phillips Screw x2 at the rear