Operating Instructions

www.snopakebrands.com 5

Quick Start Guide

Please read this manual completely before using your laminator as incorrect use

can cause serious damage. Failure to follow the instructions in this manual could

invalidate your warranty!

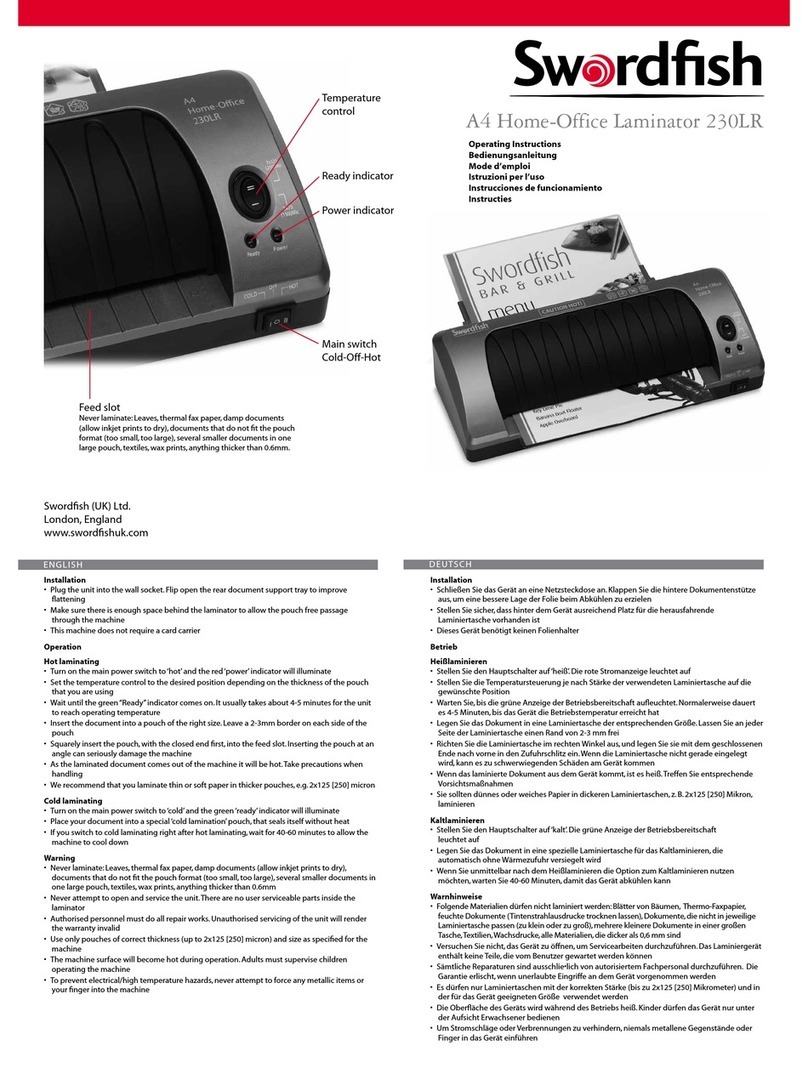

Position the laminator on a suitable at surface, within easy reach of a 13Amp socket, ensuring that there is sucient

space behind the machine for the laminations to lay at.

1

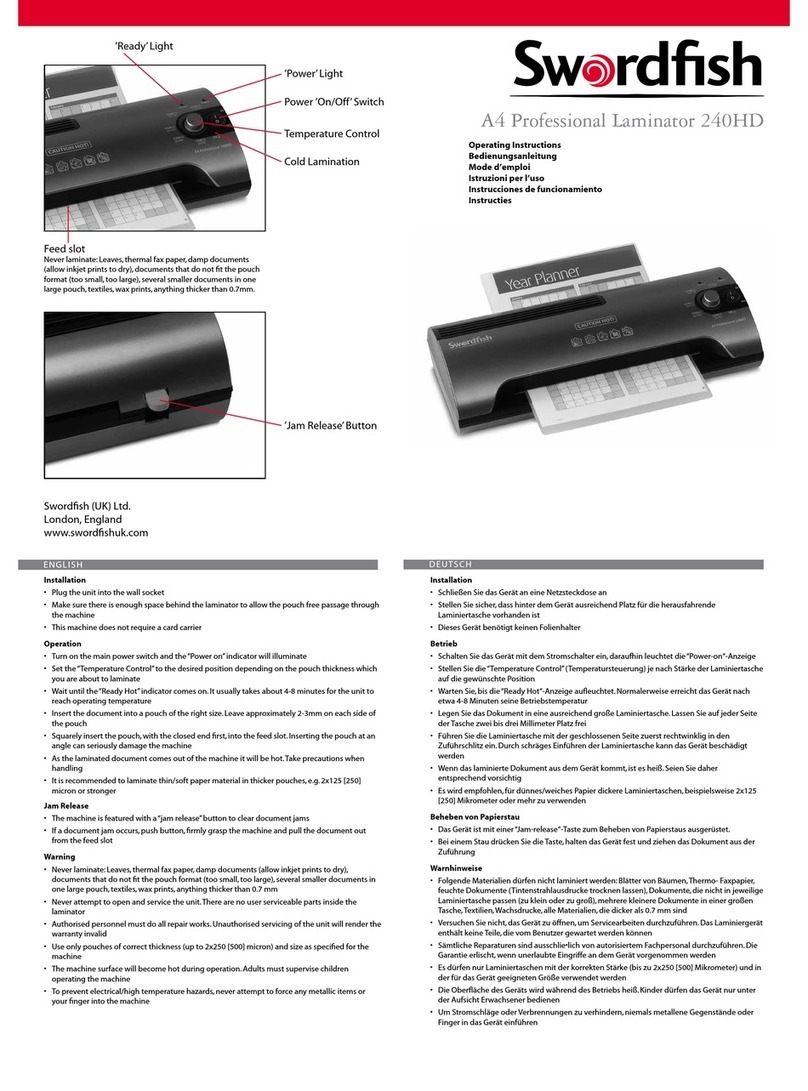

Connect the laminator to the 13Amp socket and press the isolating switch on the back of the machine to the“on”

position. The “cold” and “ready” lights will illuminate and the machine will start running in cold lamination mode.

It can be used for cold lamination immediately.

2

Press the Select button on the control panel to set the temperature, depending on the pouch thickness which you

are about to laminate and the machine will run and start warming up.

Note that setting the temperature too high can cause your pouch to jam!

3

When the appropriate temperature is reached, the ”ready” light will stop ashing and turn green. Laminating can

now begin.

4

Insert the document into a pouch of the right size. Leave approximately 2-3mm on each side of the pouch

5

To get the best results from your laminator and extend its working life, please turn to page 6.

If the lamination is imperfect, adjust the temperature to correct the fault – see page 9.

7

Before turning o the machine, press the Select button to put the machine in cold lamination mode by pressing

the Select Button. The“cold”light will illuminate. Allow the laminator to run for 5 minutes before turning o the

power. This will allow the rollers to cool evenly.

8

6You must use a pouch carrier if you intend to laminate any of the following:

• Multiple items within a single pouch

• Irregular shaped items

• Soft material such as newspaper, tissue, paper and fabrics

• Any item that leaves a border of more than a 3mm around its edges

Pouch carriers are available from your usual pouch supplier.